Pump body height adjustable buffer base

An adjustable pump body technology, applied in the direction of pump components, variable capacity pump components, vibration suppression adjustment, etc., can solve the problems of base vibration, noise generation, vibration generation, etc., to reduce noise, reduce vibration, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

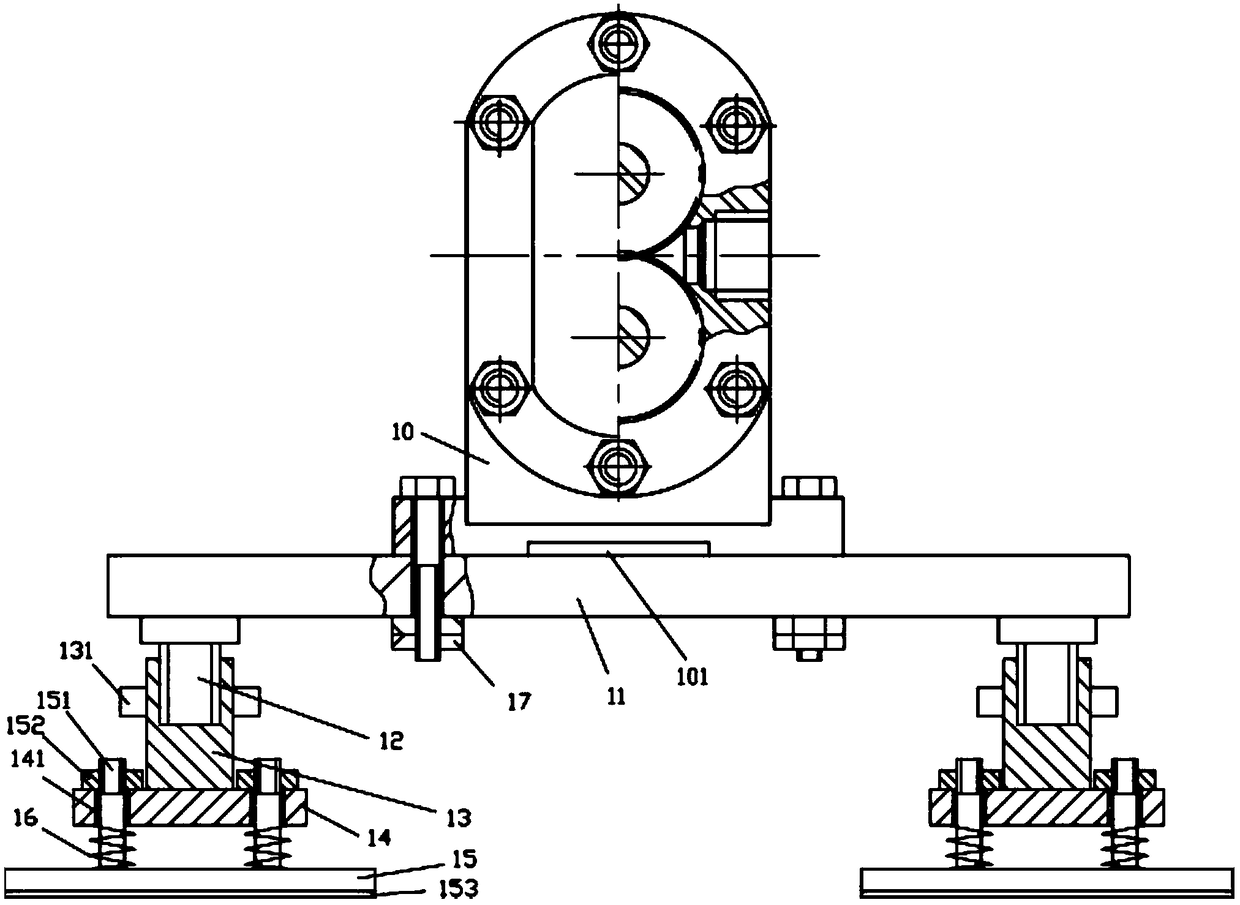

[0013] Examples, see e.g. figure 1 As shown, a pump body height adjustable buffer base includes a pump body 10 and a base body 11, and the top surface of the base body 11 is fixedly connected with the pump body 10 by bolts;

[0014] Bottom support studs 12 are fixed on the front and rear of the left and right sides of the bottom surface of the base body 11, and the vertical screw sleeve 13 is screwed in the bottom support stud 12, and the bottom end of the vertical screw sleeve 13 is fixed. There is a buffer connecting plate 14, the edge of the buffer connecting plate 14 is formed with a plurality of jacks 141, the buffer plate 15 is located directly below the buffer connecting plate 14, and the top surface of the buffer plate 15 is fixed with a plurality of vertical adjustment rods 151. The straight adjusting rod 151 is inserted into the corresponding socket 141, the top of the vertical adjusting rod 151 protrudes from the top surface of the buffer connecting plate 14 and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com