Plane point stress state detector and detection method

A technology of stress state and detector, applied in the direction of force/torque/work measuring instrument, instrument, measuring device, etc., can solve the problem that the shear stress cannot be measured, and achieve the effect of simple structure, high accuracy and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

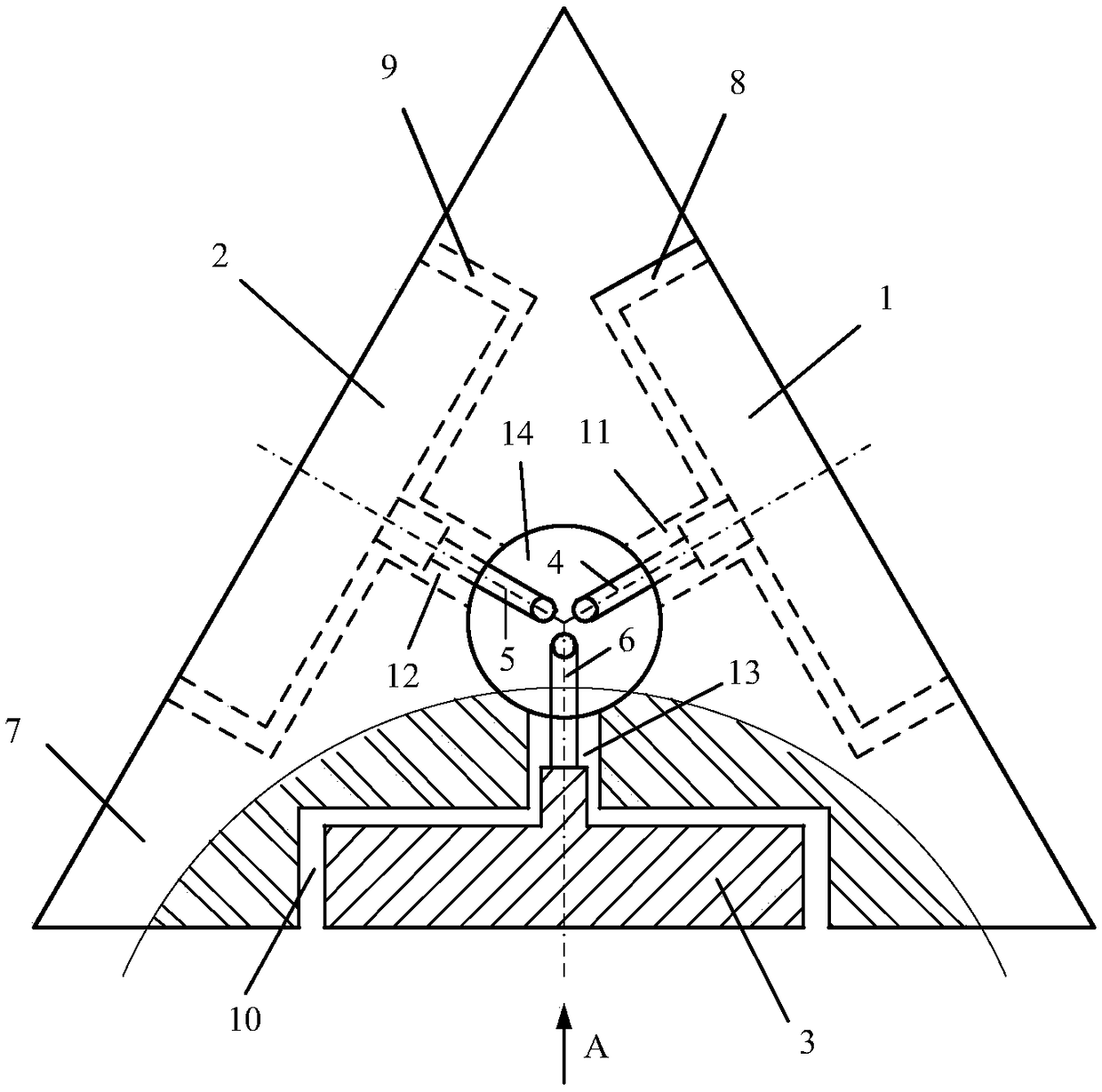

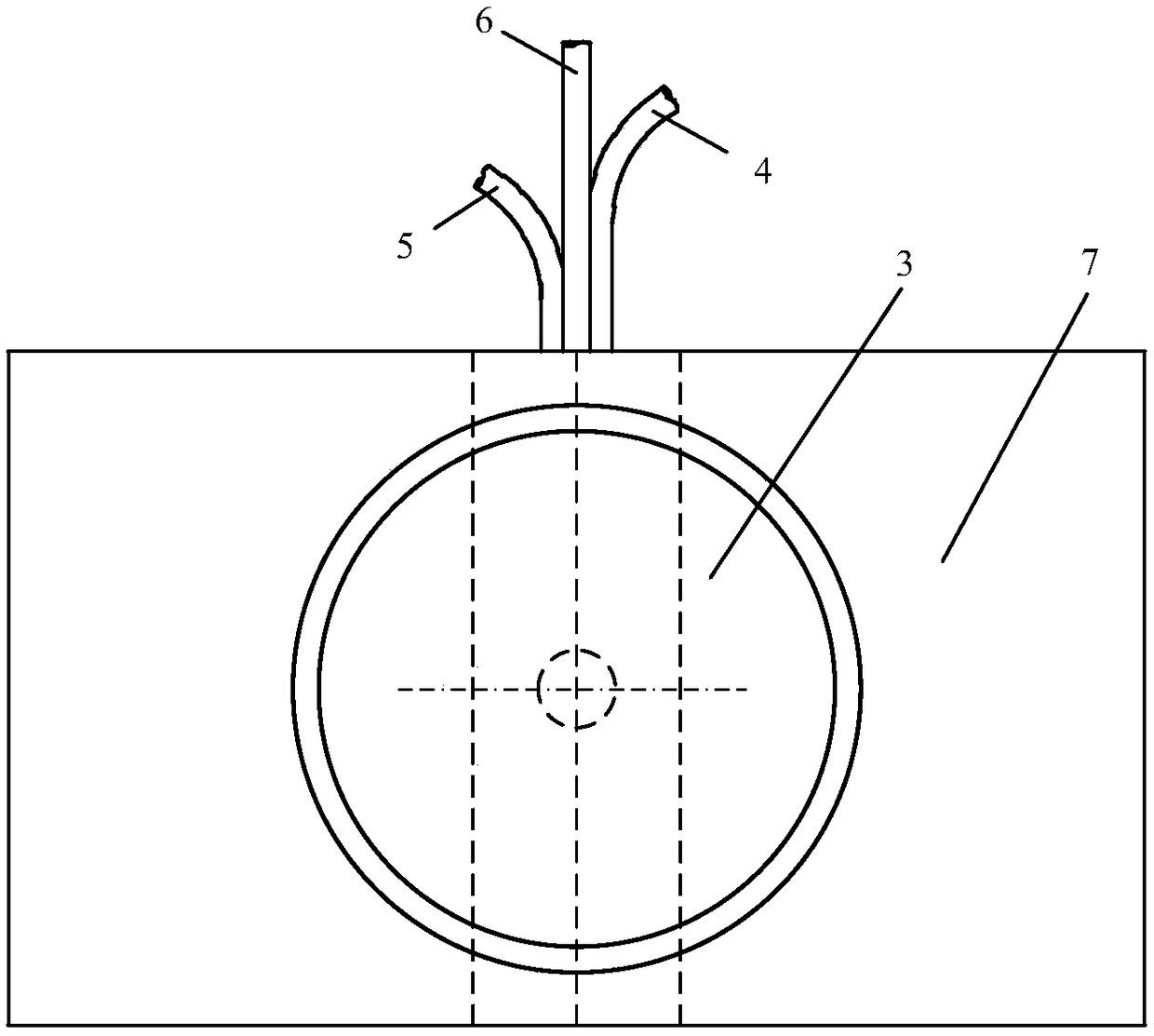

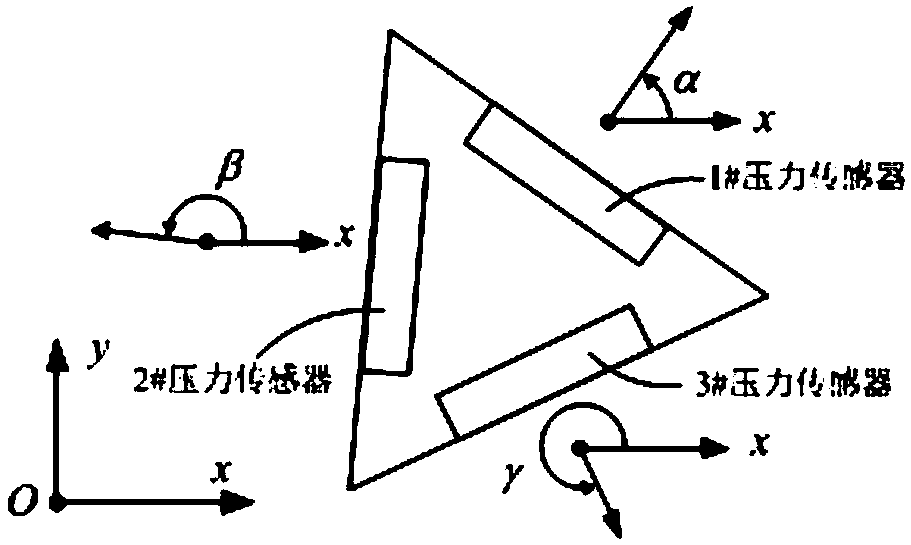

[0024] A plane point stress state detector, the detector includes a base, 3 pressure sensors and cables corresponding to the pressure sensors, such as figure 1 The base shown is a triangular prism, and the first side, the second side and the third side of the triangular prism are all provided with inserting grooves on which the pressure sensors are placed, and the center of the inserting grooves is provided with an inward extension. the cable through hole;

[0025] The center of the triangular prism is provided with an axial cable through hole, and the axial cable through hole communicates with the cable through hole.

[0026] Specifically, the embedding grooves of the first side, the second side and the third side of the triangular prism are located at the same horizontal position of the triangular prism, and the sensing surface of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com