Intelligent management electronic point inspection system and equipment based on voice interaction

A point-checking system and voice interaction technology, applied in voice analysis, voice recognition, registration/instruction of machine work, etc., can solve problems such as untimely data entry, handwriting misrecording, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

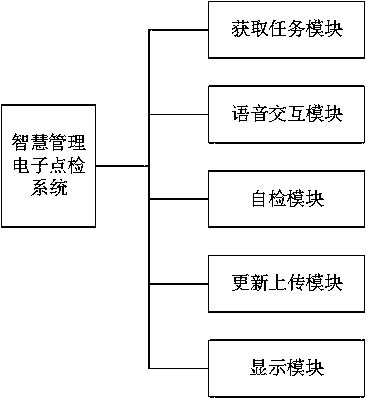

[0057] Such as figure 1 As shown, it is a block diagram of an intelligent management electronic inspection system based on voice technology in the present invention.

[0058]An intelligent management electronic spot inspection system based on voice technology, including:

[0059] Obtain task module, used to obtain check task items;

[0060] The voice interaction module is used to realize voice interaction and recognize and analyze the received voice;

[0061] The self-inspection module is used to perform self-inspection on all the updated point inspection task items, obtain the task completion degree, judge the accuracy of the data in the task item, and obtain the correct point data;

[0062] The update upload module is used to input the error-free point data into the corresponding inspection task item, update the status of the task item and upload it to the smart management database.

[0063] This technical solution is based on the hand-held electronic spot inspection equi...

Embodiment 2

[0065] Based on embodiment 1, the difference from embodiment 1 is:

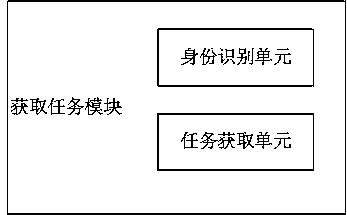

[0066] Such as figure 2 As shown, it is a block diagram of the acquisition task module of the present invention.

[0067] The acquisition task module includes:

[0068] Identity recognition unit, used to identify the identity information of full-time checkers;

[0069] The task acquisition unit is configured to obtain the corresponding check task item according to the identity information of the full-time check inspector.

[0070] The acquisition task module correspondingly obtains the check task items to be operated by the full-time check inspector by identifying the identity information of the full-time check inspector. In a large-scale enterprise, different full-time check inspectors may Responsible for different equipment spot checks, obtain identity information, and carry out spot checks more accurately. A dedicated person is responsible for a specific task item.

[0071] Furthermore, while obtaini...

Embodiment 3

[0098] The method of use when performing task items for the full-time checker based on the system of Embodiment 2:

[0099] Step 1, pre-install the local voice database in the intelligent management electronic spot inspection system.

[0100] Step 2, the hand-held electronic spot inspection device reminds the full-time spot inspector of the tasks to be performed by voice.

[0101] Step 3, the full-time checker performs the task, and obtains the current voice input of the full-time checker by holding the electronic check device.

[0102] Step 4: Analyze the voice, obtain the corresponding voice features, identify data in a targeted manner, use the local voice library to generate corresponding text from the acquired voice features, and synchronize the text to the screen interface on the temporary data bar of the task item.

[0103] Step 5, when the voice input is completed, enter the self-inspection module to perform self-inspection, confirm that there is no error point data an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com