Positioning tool for top cover outer plate

A technology for positioning tooling and top covers, which is applied in the direction of tool storage devices, workpiece clamping devices, auxiliary devices, etc., and can solve the problems of inconsistency in state, inconsistency in grasping the position and angle of the outer plate of the top cover, and the welding quality of the car body top cover assembly Inconsistency and other problems, to achieve the effect of ensuring consistency, reliable and effective positioning, and improving the quality of assembly welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

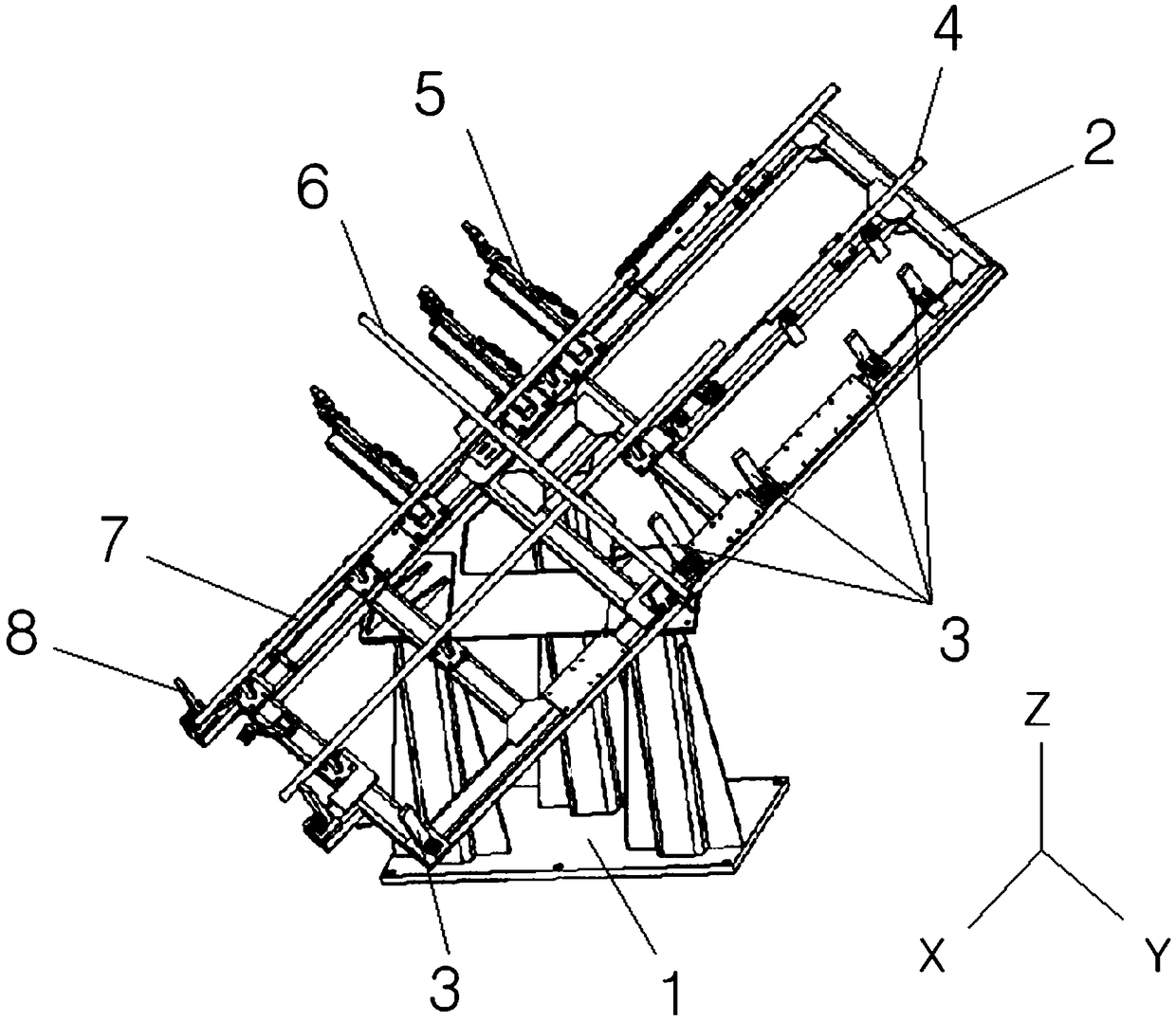

[0029] The present invention will be further described below in conjunction with the drawings.

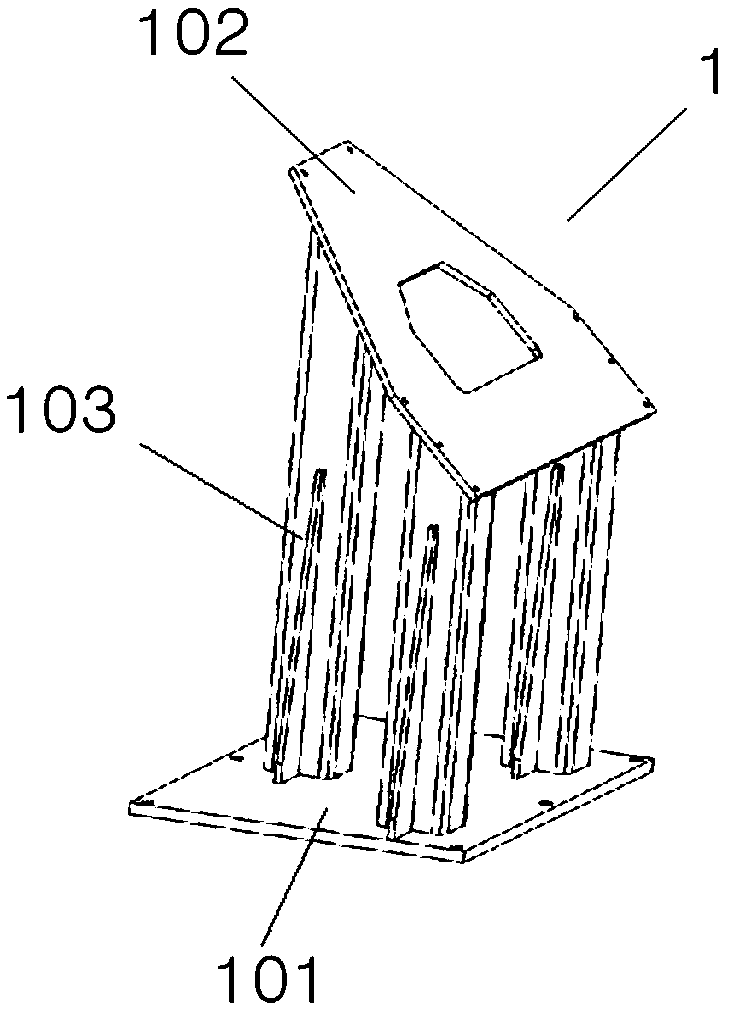

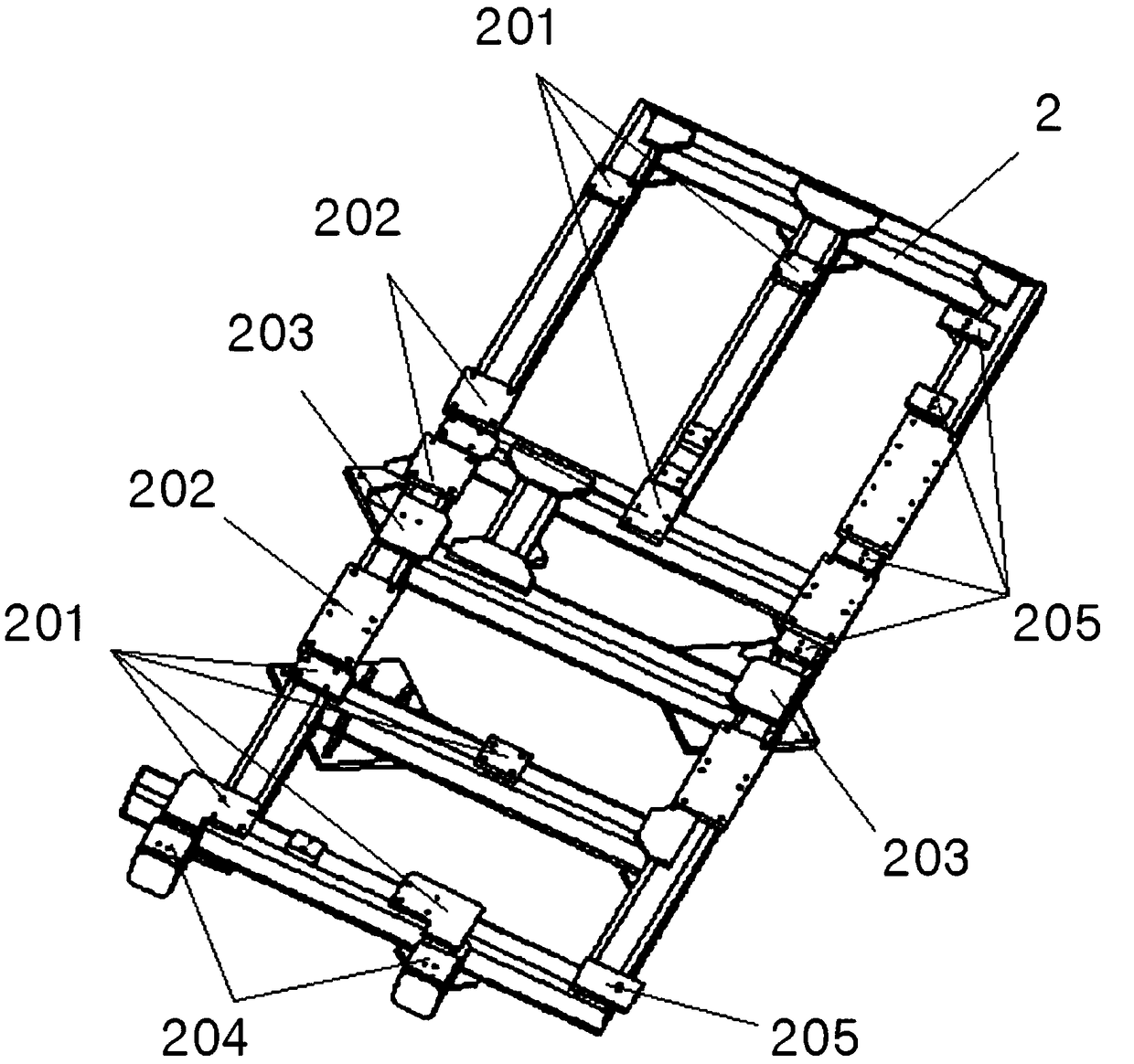

[0030] See Figure 1 to Figure 9 The positioning tool for the outer panel of the top cover shown includes a support 1, a base plate 2, an X-direction sliding track, a Y-direction sliding track 6, an X-direction positioning block 8, a Y-direction positioning block 3, and a correction unit 5; The support 1 includes a bottom plate 101, a support column 103 fixed on the bottom plate 101 by vertical welding, and a substrate mounting surface 102 fixed on the top of the support column 103 by oblique welding; the bottom surface of the substrate 2 is welded with a substrate connecting plate 206, the substrate 2 The substrate connecting plate 206 is fixedly connected with the substrate mounting surface 102 on the top of the substrate 2 with bolts; the X-direction sliding rail and the Y-direction sliding rail 6 are laid vertically and crossed on the top surface of the substrate 1, and sliding in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com