A high-temperature heating device, printer and printing process of an fdm printer

A technology of process and heating temperature, applied in the direction of additive processing, manufacturing auxiliary devices, processing heating elements, etc., can solve the problems of irregular shrinkage of printing filaments, and achieve regular shrinkage, uniform ejection, and smooth transition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

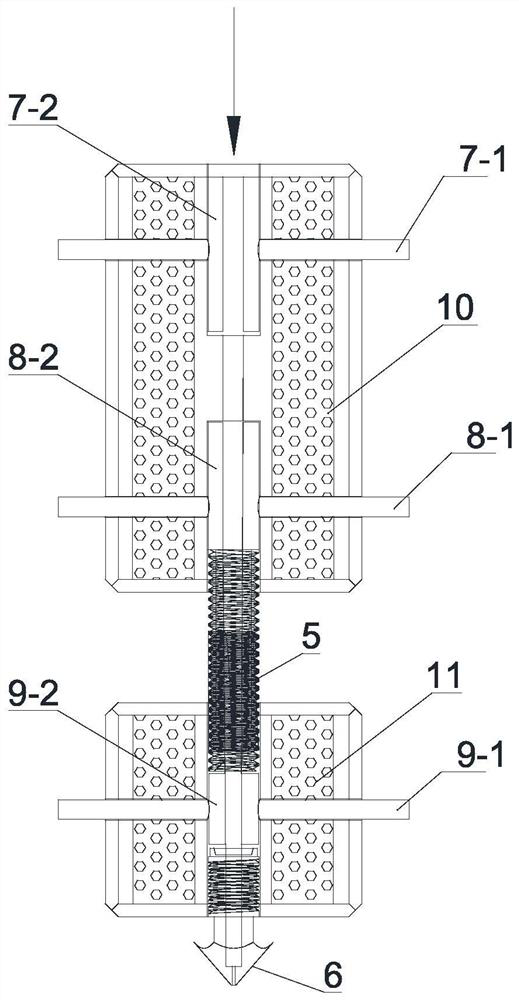

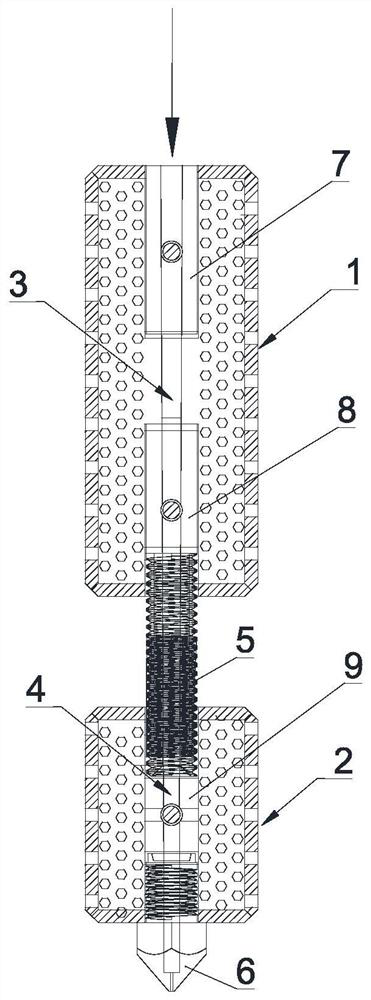

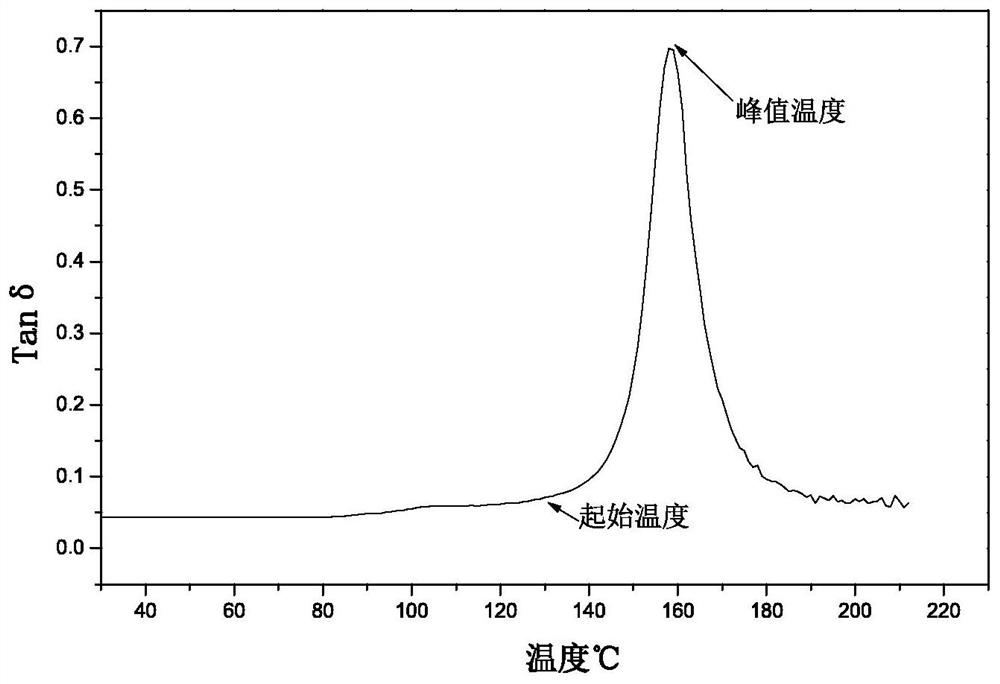

[0036] see figure 1 and figure 2 A high-temperature heating device for an FDM printer of the present invention includes a first heating module 1 for heating the printing filament from a glass state to a high elastic state and a first heating module 1 for heating the printing filament from a high elastic state to The second heating module 2 is heated to the viscous state, wherein, the first heating module 1 is provided with a first printing filament conveying channel 3 for printing filament movement, and the second heating module 2 is provided with a printing filament The second printing filament delivery channel 4 where the material continues to move, one end of the first printing filament delivery channel 3 is connected to the printing filament feeding device, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com