Single-girder bridge crane composite end beam

A bridge crane and single-girder technology, which is applied in the field of hoisting machinery, can solve the problems that the lifting tonnage of single-girder bridge crane cannot meet the production demand, increase the lifting tonnage, increase user investment, etc., and achieve the purpose of increasing the traveling capacity of the cart , increase the lifting tonnage, improve the effect of economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

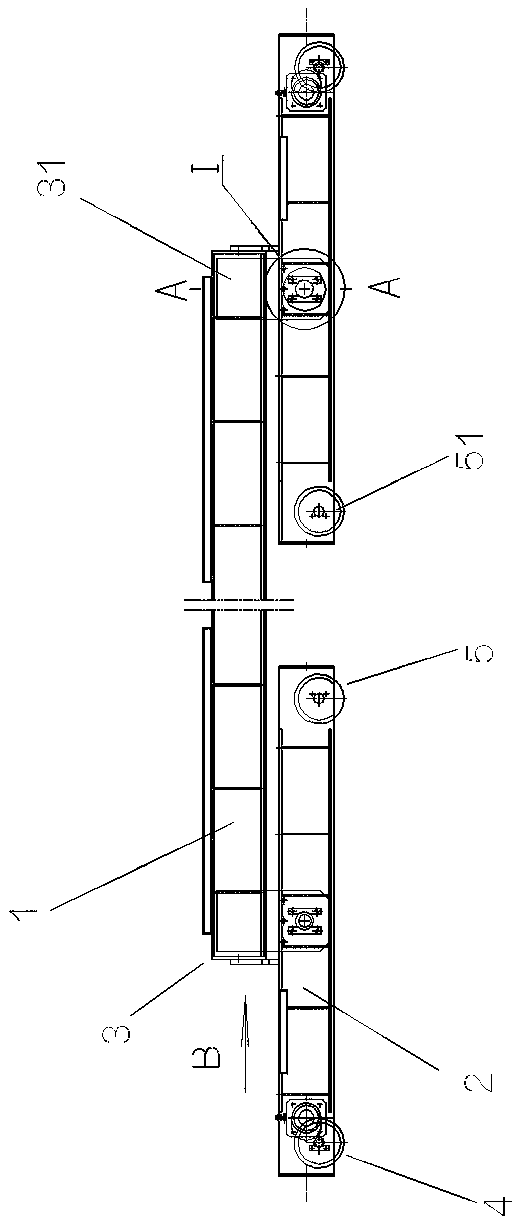

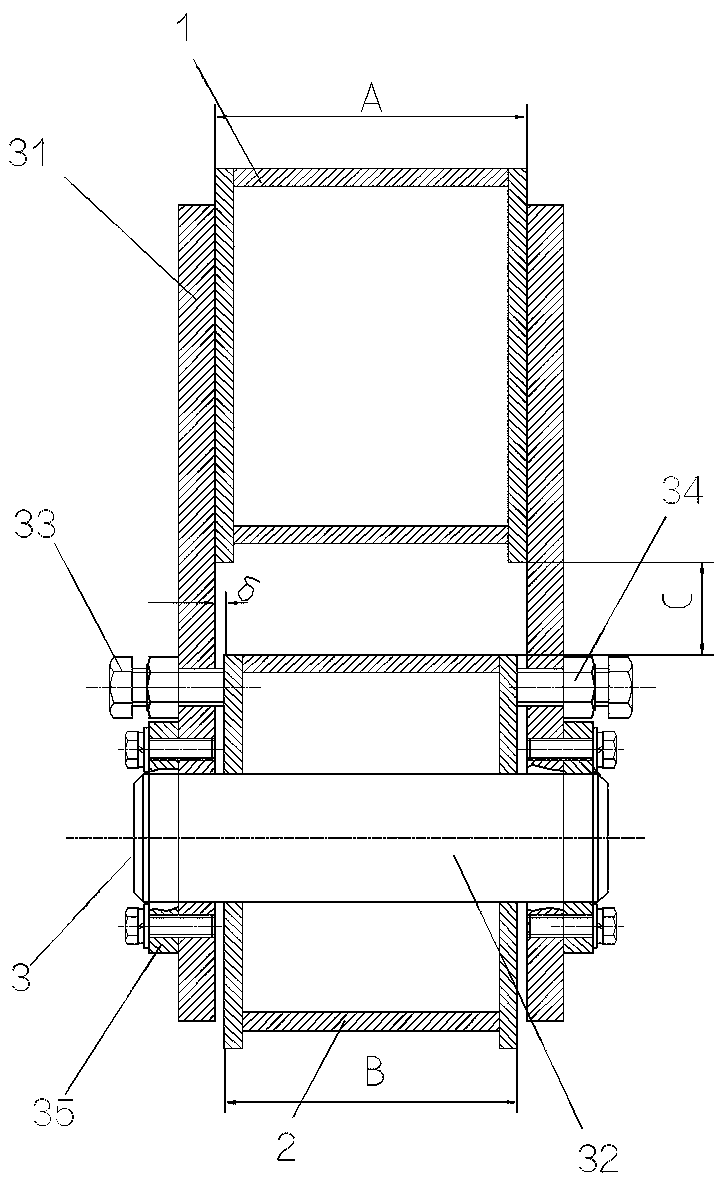

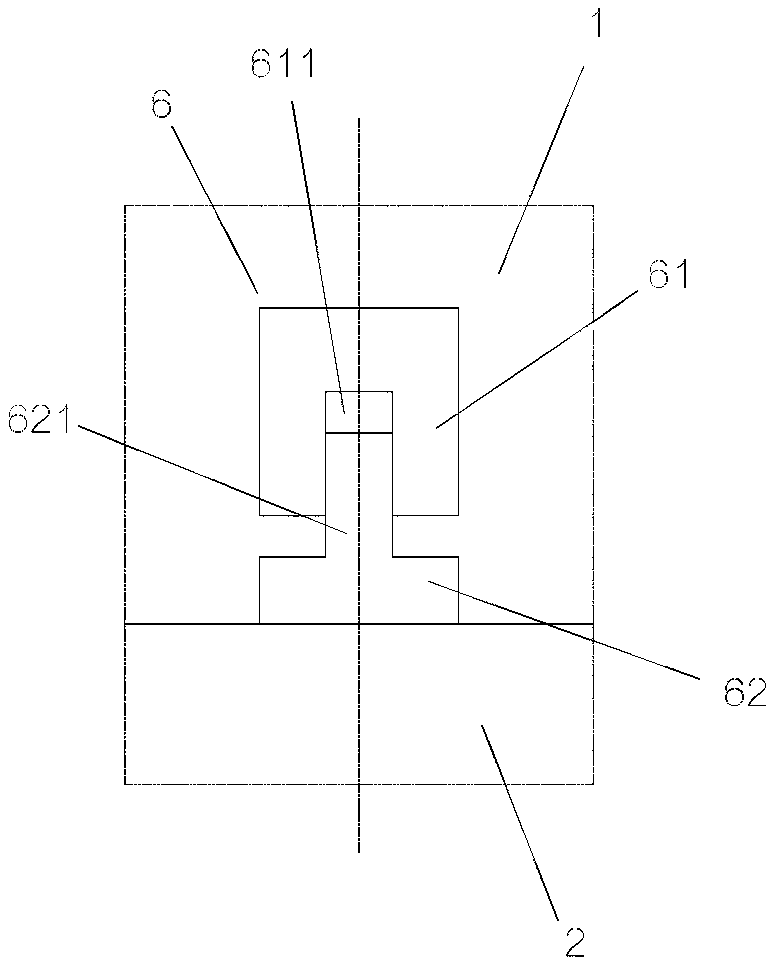

[0020] like Figure 1 to Figure 4 As shown, the present invention includes an upper end beam 1, two lower end beams 2 and hinged devices 3 respectively arranged between the two ends of the upper end beam 1 and the two lower end beams 2, one upper end beam 1 and two spaced apart The lower end beam 2 is arranged in the form of finished products up and down, and the two ends of the upper end beam 1 are respectively hinged to the middle part of the corresponding lower end beam 2 through the hinge device 3 . A drive wheel set 4 and a driven wheel set 5 are respectively arranged at both ends of each lower end beam 2 . The structure in which the four wheels 51 in the two lower end beams 2 are arranged in a straight line and supported on the crane rail on the corresponding side, and the increase in wheelbase between the frontmost wheel and the endmost wheel of the two lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com