Track cable car

A technology of rail cables and distribution beams, applied in the field of rail cable cars, can solve the problems of huge material consumption and achieve high economic benefits, long service life and low wheel pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

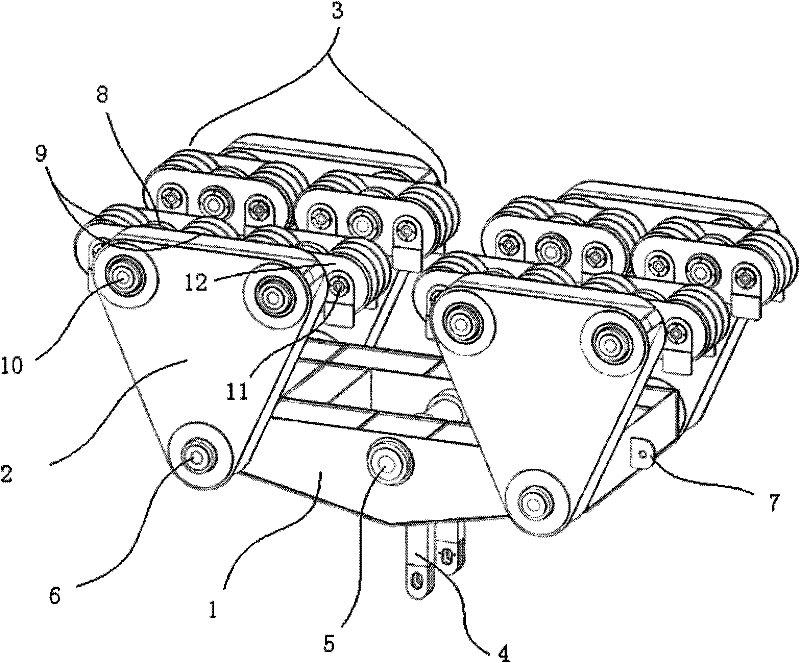

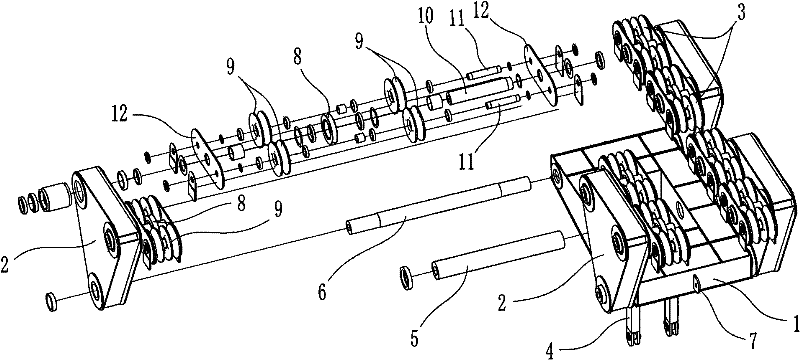

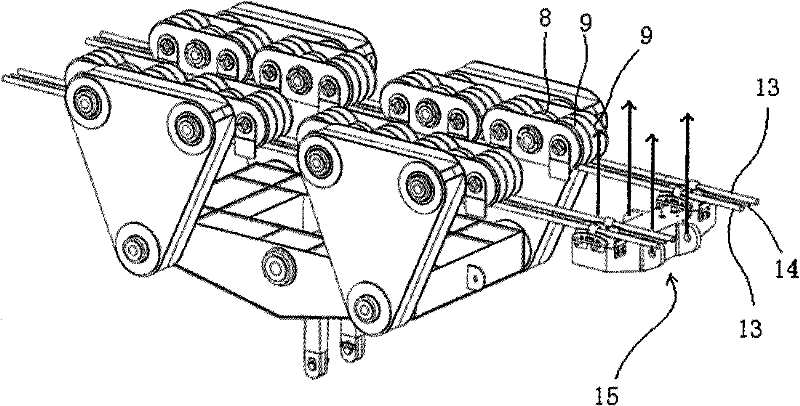

[0013] Such as figure 1 , figure 2 As shown, the rail cable car includes a rectangular distribution beam 1, a triangular distribution beam 2, a rail cable wheel group 3, a load spreader 4, a load bearing shaft 5, and a triangular distribution beam shaft 6; The middle part of the rectangular distribution beam 1; the triangular distribution beam 2 is an inverted triangle and is symmetrically arranged on both sides of the rectangular distribution beam 1 through the triangular distribution beam axis 6, and each side of the rectangular distribution beam 1 is provided with two triangular distribution beams 2, and the triangular distribution beam 2 The bottom of the beam 2 is connected with the triangular distribution beam shaft 6, and the cable pulley group 3 is arranged on the upper part of the triangular distribution beam 2 through the shaft 10, and the cable pulley group 3 provided on each triangular distribution beam 2 includes two front and rear cable pulleys Unit, each track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com