Horizontal Guide Mechanism with Large Wheel Base for Ring Crane

A technology of guiding mechanism and crane, applied in the direction of support structure, load hanging element, transportation and packaging, etc., can solve the development requirements that cannot meet the large-scale development of nuclear power machinery, the horizontal guiding mechanism has a small wheel base, and the horizontal wheel bears high pressure, etc. problems, to achieve the effect of large wheel-span ratio, stable operation and reduction of horizontal wheel pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

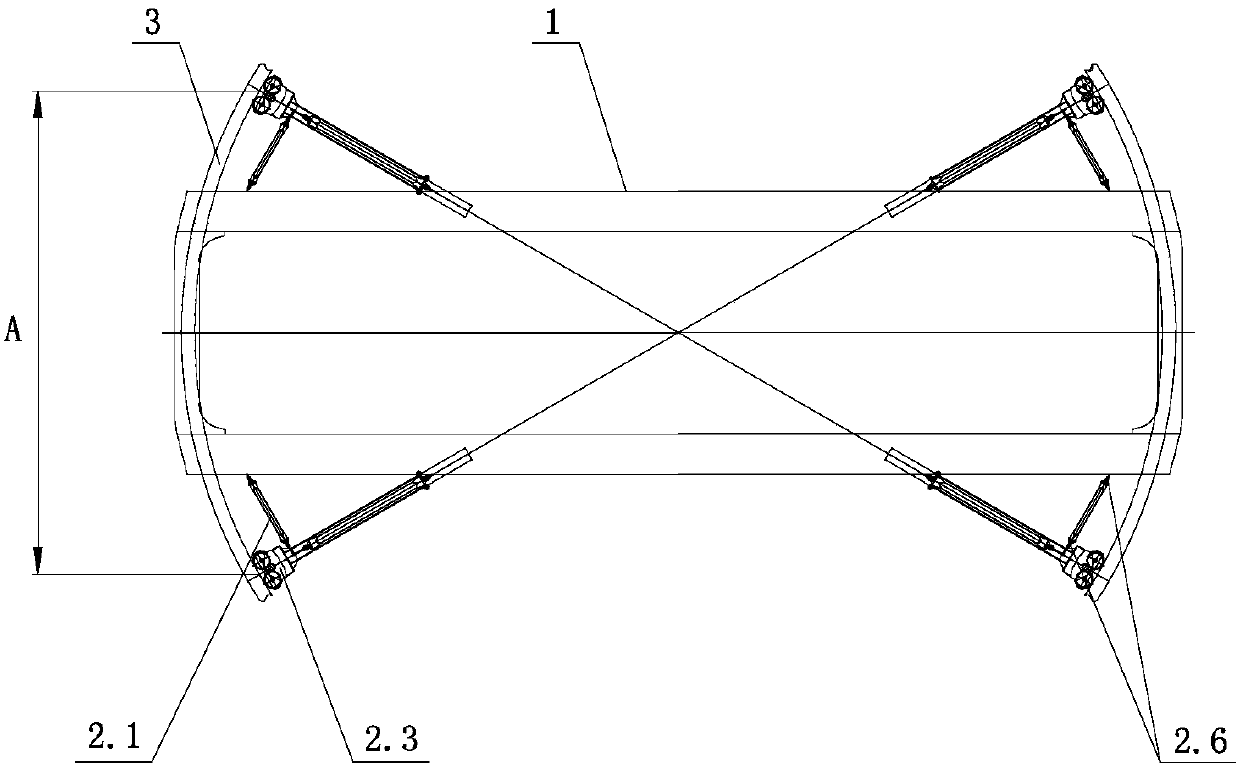

[0032] Such as Figure 1 to Figure 4 The large wheelbase horizontal guide mechanism for the ring crane shown is composed of four corner horizontal guide mechanisms respectively arranged on the four corners of the horizontal plane of the ring crane to realize horizontal guidance through the joint action;

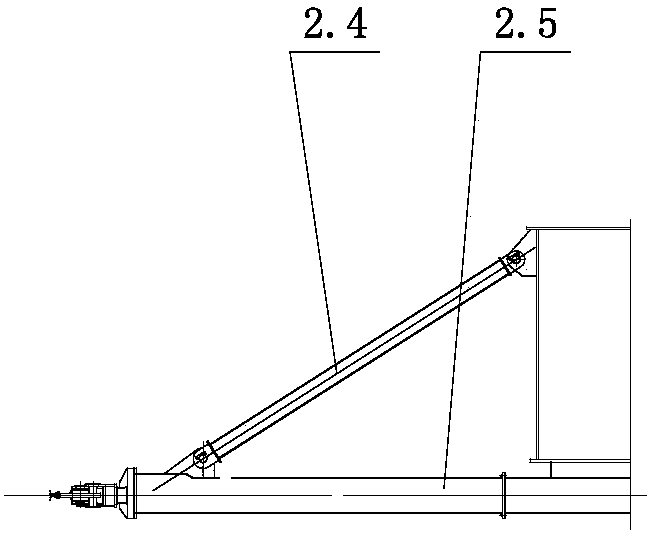

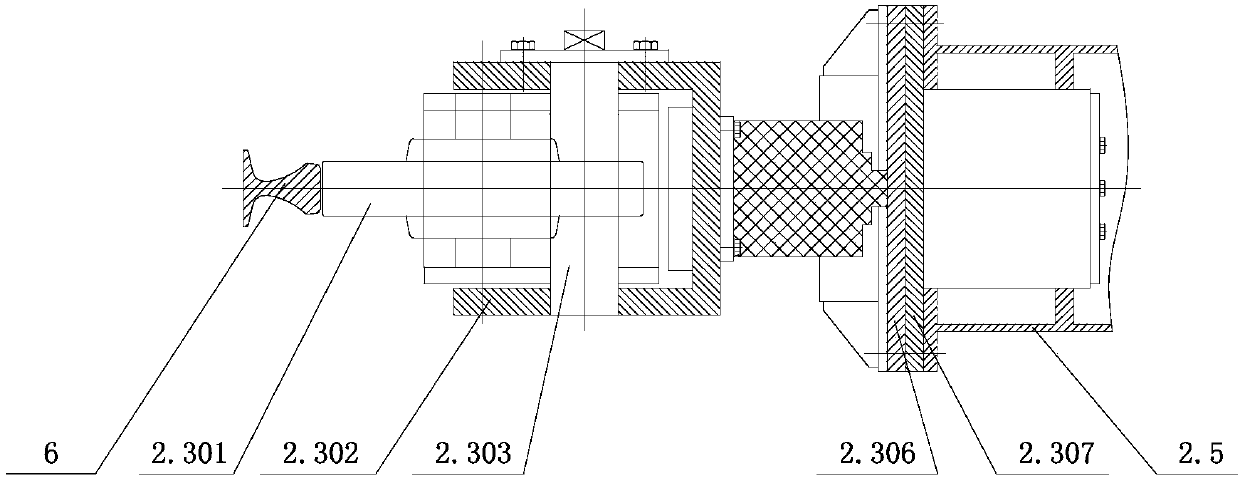

[0033] Each corner horizontal guide mechanism includes: horizontal support 2.1, horizontal guide wheel 2.3, oblique support 2.4 and support rod 2.5;

[0034] The support rod 2.5 is the main load-bearing part and is a long rod part. The horizontal guide wheel 2.3 is installed on the head, and the root is fixed under the side of the main girder 1 of the bridge frame of the ring crane. The support rod 2.5 firmly supports the horizontal guide wheel 2.3 on the main girder of the bridge frame. Outer 1 side, and the support rod 2.5 extends outward relative to the side wall of the ring crane bridge girder 1 from the root to the head;

[0035] The oblique support 2.4 is a supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com