Measuring method and system of optical axis center and angle of view of camera movement

A measurement method and camera technology, applied in the field of cameras, can solve problems such as complex workload of offset data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

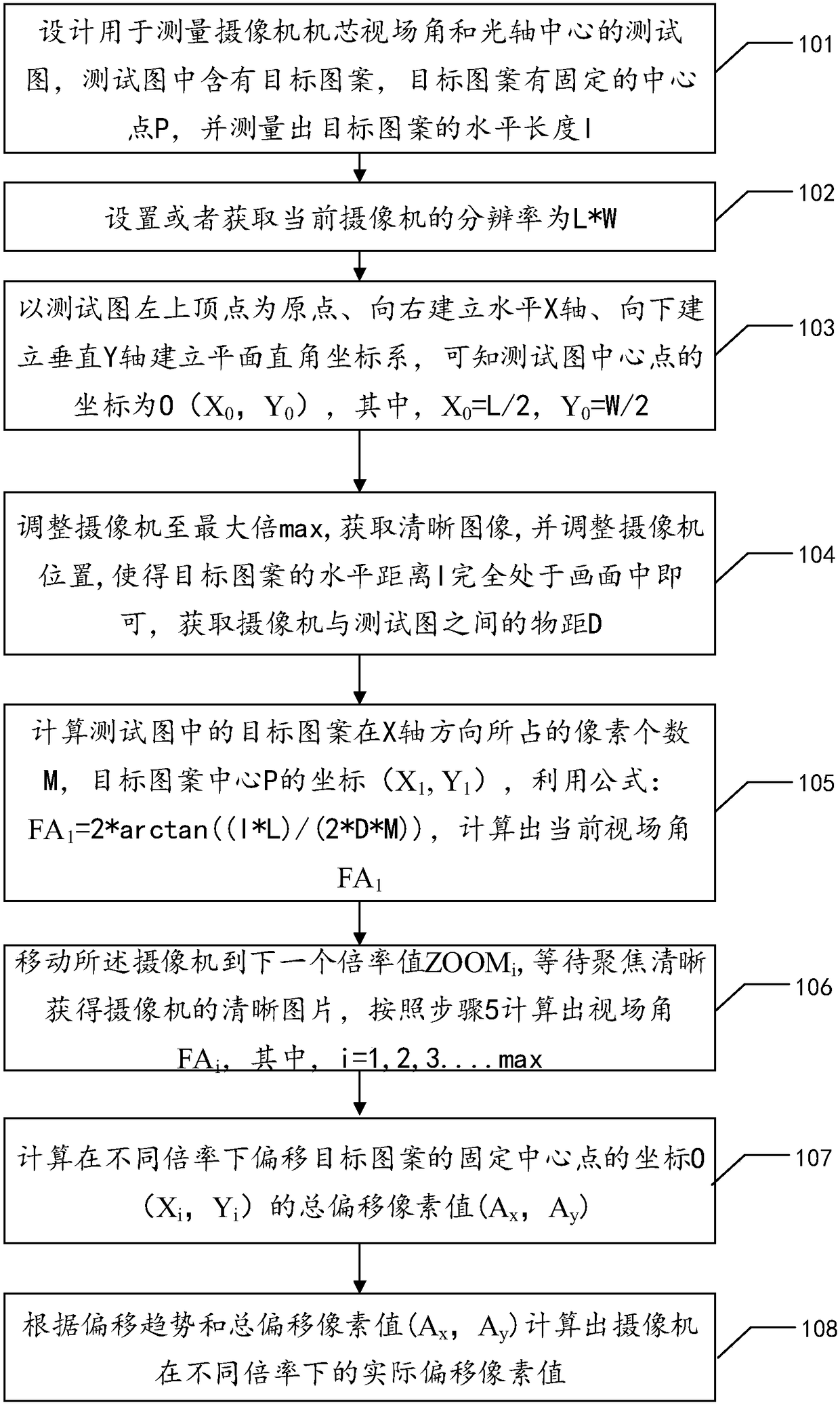

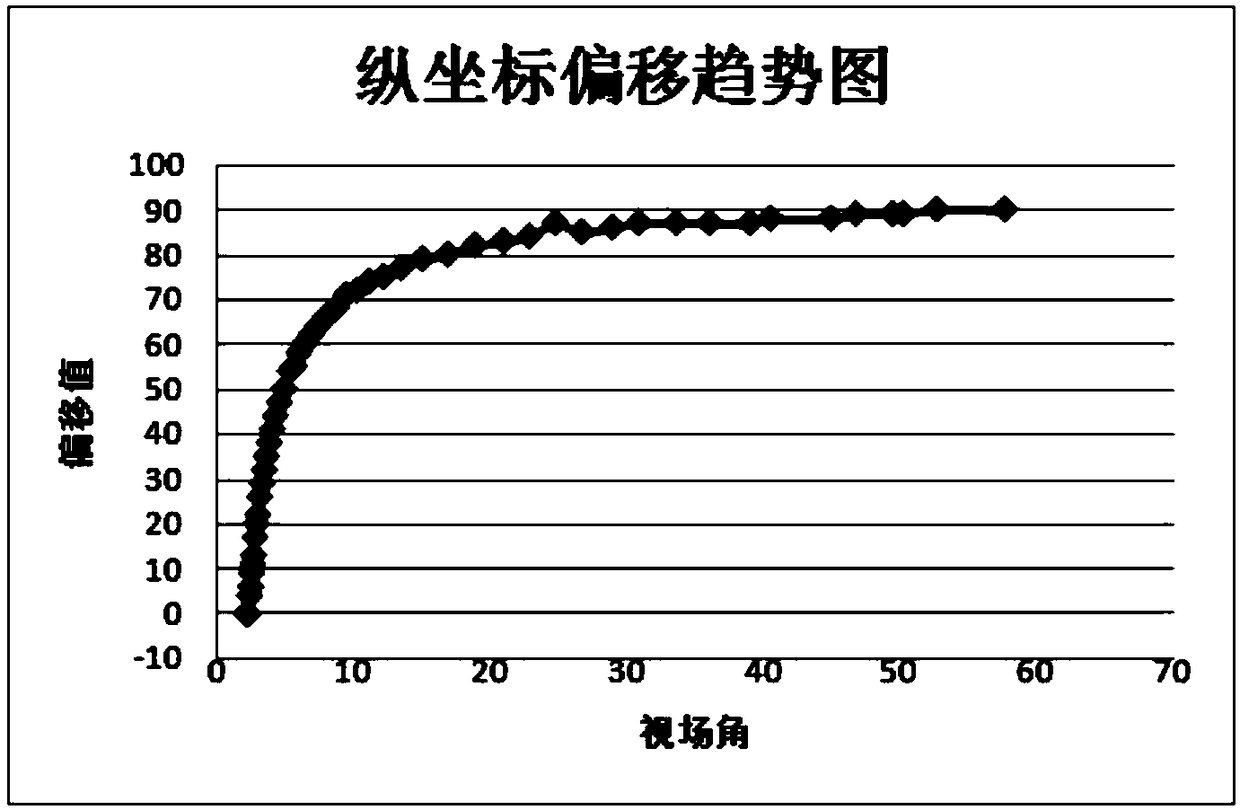

[0076] figure 1 It is a schematic flow chart of this embodiment, a method for measuring the field of view angle of a camera movement and the center of an optical axis, comprising:

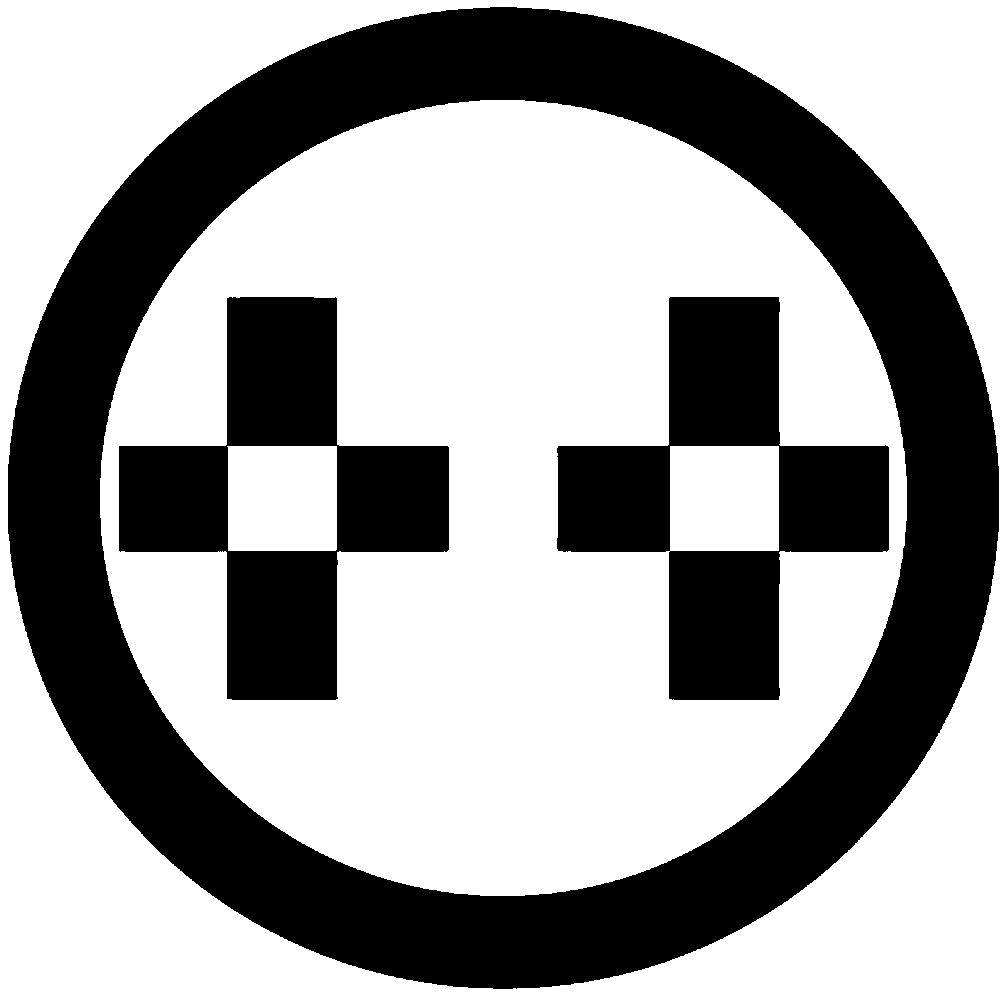

[0077] Step 101, designing a test chart for measuring the field of view angle of the camera movement and the center of the optical axis, the test chart contains a target pattern, the target pattern has a fixed center point P, and the horizontal length l of the target pattern is measured;

[0078] It should be noted that in order to solve the data of simultaneously measuring the field of view and optical axis offset, it is necessary to design the test chart reasonably. In this embodiment, the principle of measuring the angle of view is to use the original resolution of the test chart and the known distance (horizontal length l of the target pattern) and the target pattern of the pixel value in the test chart to calculate the actual horizontal direction of the entire picture of the camera in proporti...

Embodiment 2

[0141] Figure 5 It is a schematic diagram of the structure of this embodiment, a measurement system for the angle of view of the camera movement and the center of the optical axis, including:

[0142] The measurement preparation unit 201 is used to establish and obtain data for measuring the field of view angle of the camera movement and the center of the optical axis;

[0143] An angle of view measuring unit 202, used to measure the angle of view of the camera movement;

[0144] The optical axis center measuring unit 203 is used for measuring the offset of the optical axis center of the camera movement.

Embodiment 3

[0146] Image 6 It is a schematic diagram of the structure of this embodiment, a measuring device for the angle of view of the camera core and the center of the optical axis, including:

[0147] The measurement preparation unit 301 is used to establish and obtain data for measuring the field of view angle of the camera movement and the center of the optical axis;

[0148] The test chart design module 3011 is used to design a test chart for measuring the field of view angle of the camera movement and the center of the optical axis, the test chart contains a target pattern, the target pattern has a fixed center point P, and the target pattern is measured The horizontal length l;

[0149] A resolution acquisition module 3012, configured to set or acquire the resolution of the current camera as L*W;

[0150] The coordinate system establishment module 3013 is used to set up the horizontal X axis with the upper left vertex of the test chart as the origin, establish the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com