Explosion-proof cabinet high in security coefficient

A safety factor, explosion-proof cabinet technology, applied in the field of explosion-proof cabinets, can solve the problems of low safety factor, single structure, increased loss, etc., and achieve the effect of high degree of intelligent automation, improved safety factor, and improved locking strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

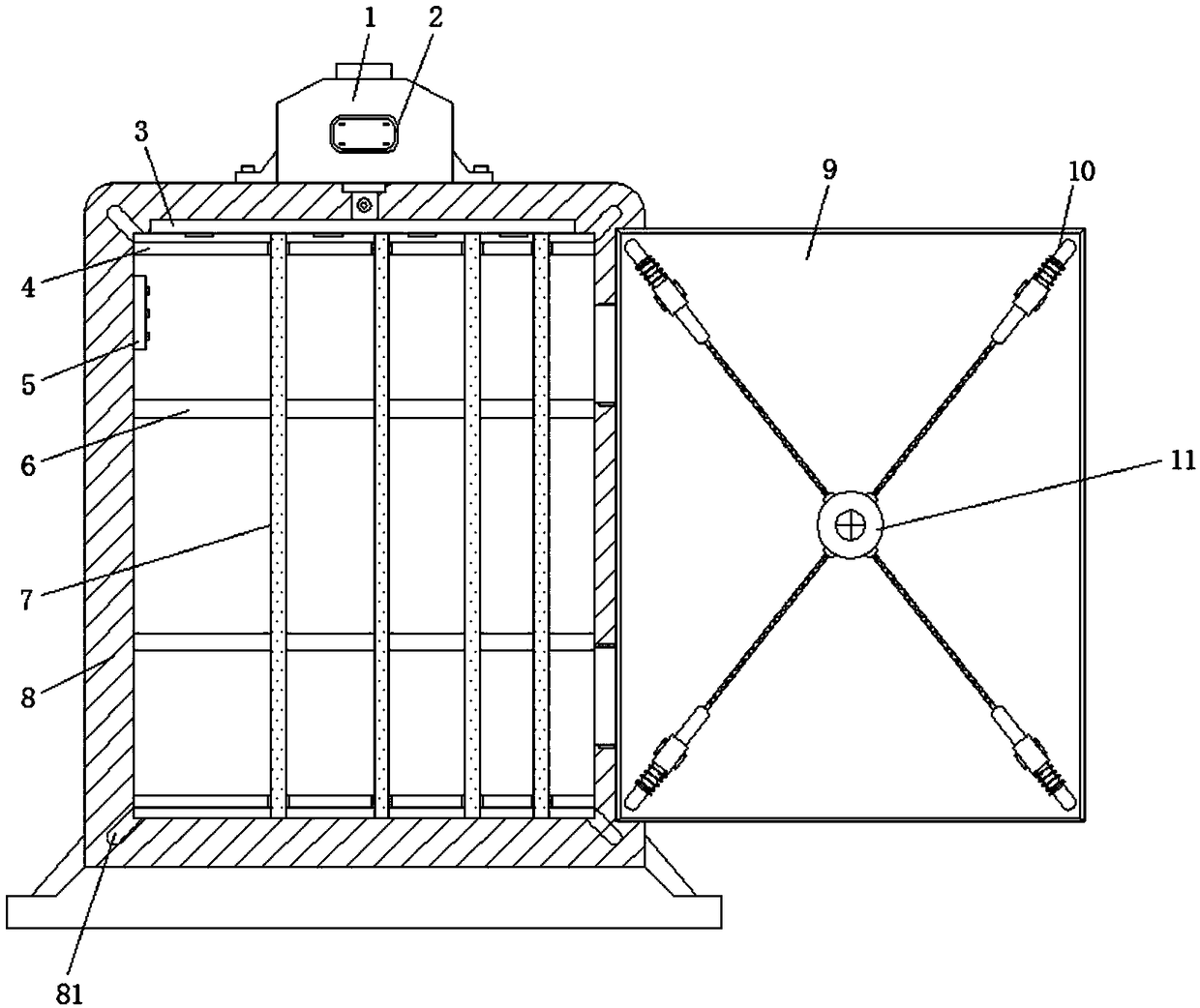

[0026] Example one, reference figure 1 with Figure 5 , An explosion-proof cabinet with a high safety factor, including a cabinet body 8 and a cabinet door 9. The inner surface walls of the cabinet body 8 are equidistantly arranged with multiple layers 6 from top to bottom, and the front sides of the multiple layers 6 A fixed rod 7 is vertically arranged, and the vertical end of the rear surface wall of the fixed rod 7 is welded with multiple partitions 17 at equal intervals. The upper and lower sides of the cabinet body 8 are welded with sliding rods 4 along the horizontal ends. The partitions 17 at the upper and lower ends of the plate 17 are slidably connected to the sliding rod 4, and the spacing between the two partitions 17 is equal to the thickness of the side plate 9. Through the sliding action of the partition 17 on the sliding rod 4, The items can be placed in zones according to the nature and size of the items. On the one hand, the items can be placed more organized a...

Embodiment 2

[0027] Example two, reference figure 1 with Figure 4 , The horizontal end of the top inner surface wall of the cabinet body 8 is fixedly connected with a horizontal pipe 3, and the top center of the horizontal pipe 3 communicates with the fire extinguisher 1 fixed on the top outer surface wall of the cabinet body 8 through the main pipe 16. The fire extinguisher 1 is provided with AVR The central control processor 2, the bottom of the horizontal pipe 3 is equidistantly arranged with a plurality of nozzles 31 along the horizontal end, the cabinet 8 is provided with a temperature sensor 5, the temperature sensor 5 is used to monitor the internal temperature of the cabinet 8 in real time, the main pipeline 16 A solenoid valve 161 is provided on the upper part. The output terminal of the temperature sensor 5 is electrically connected to the input terminal of the AVR central control processor 2, and the output terminal of the AVR central control processor 2 is electrically connected ...

Embodiment 3

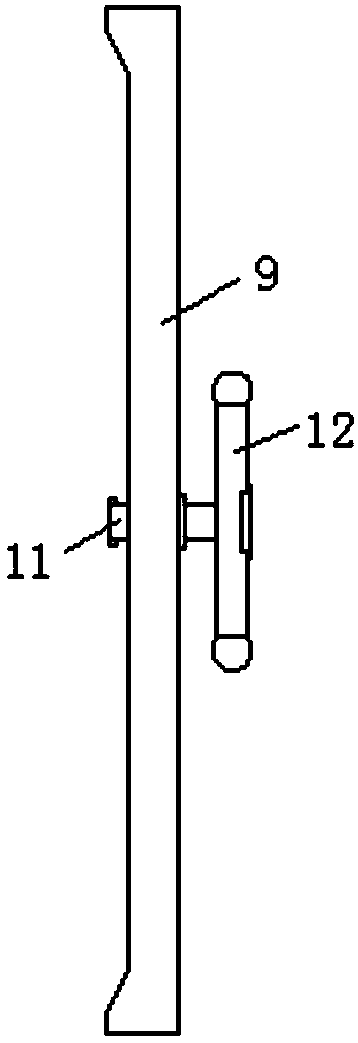

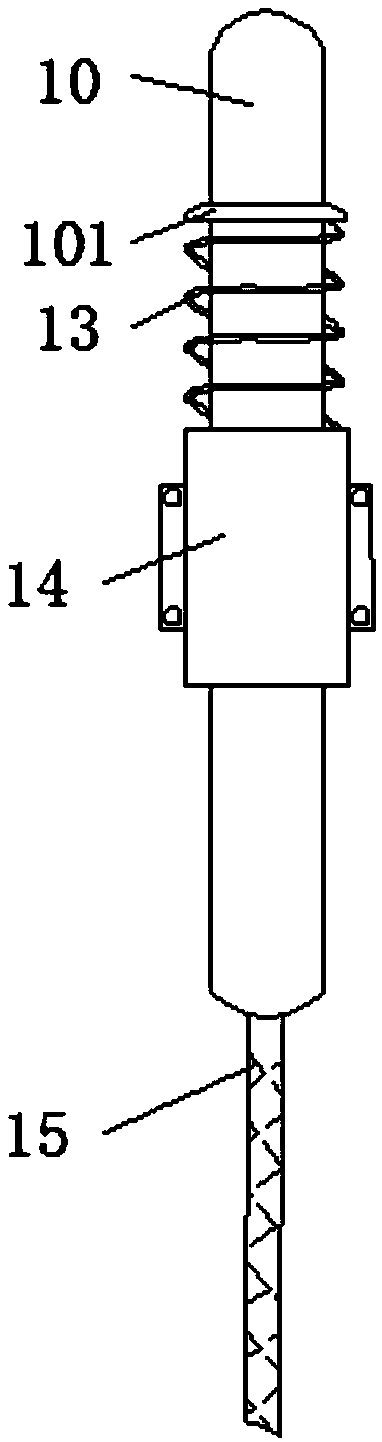

[0028] Example three, reference Figure 1-3 , The front end of one side of the cabinet body 8 is movably connected with a cabinet door 9 through a hinge. The four right angles of the rear surface of the cabinet door 9 are welded with a limit sleeve 14, and the orientation of the limit sleeve 14 faces the right angle of the cabinet door 9. The setting of the limit sleeve 14 can limit the lateral displacement of the limit bolt 10 to avoid position deflection during the movement. The inside of the limit sleeve 14 is sleeved with the limit bolt 10, and the limit bolt 10 is located on the limit pin 10. The outer part of the position sleeve 14 is welded with a limit piece 101, and the limit piece 101 is elastically connected to the limit sleeve 14 through a return spring 13 sleeved on the outside of the limit sleeve 14. The return spring 13 is used to provide the limit pin 10 for automatic entry The elastic force required inside the limit hole 81, the end of the limit bolt 10 at a ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com