Heating and drying oven capable of conveniently taking and placing experimental vessel

A technology for heating and drying experimental vessels, which is applied in the direction of static material dryers, drying chambers/containers, local agitation dryers, etc., which can solve the problems of increasing power consumption, scalding operators, and inconvenient removal of vessels, so as to avoid burns Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

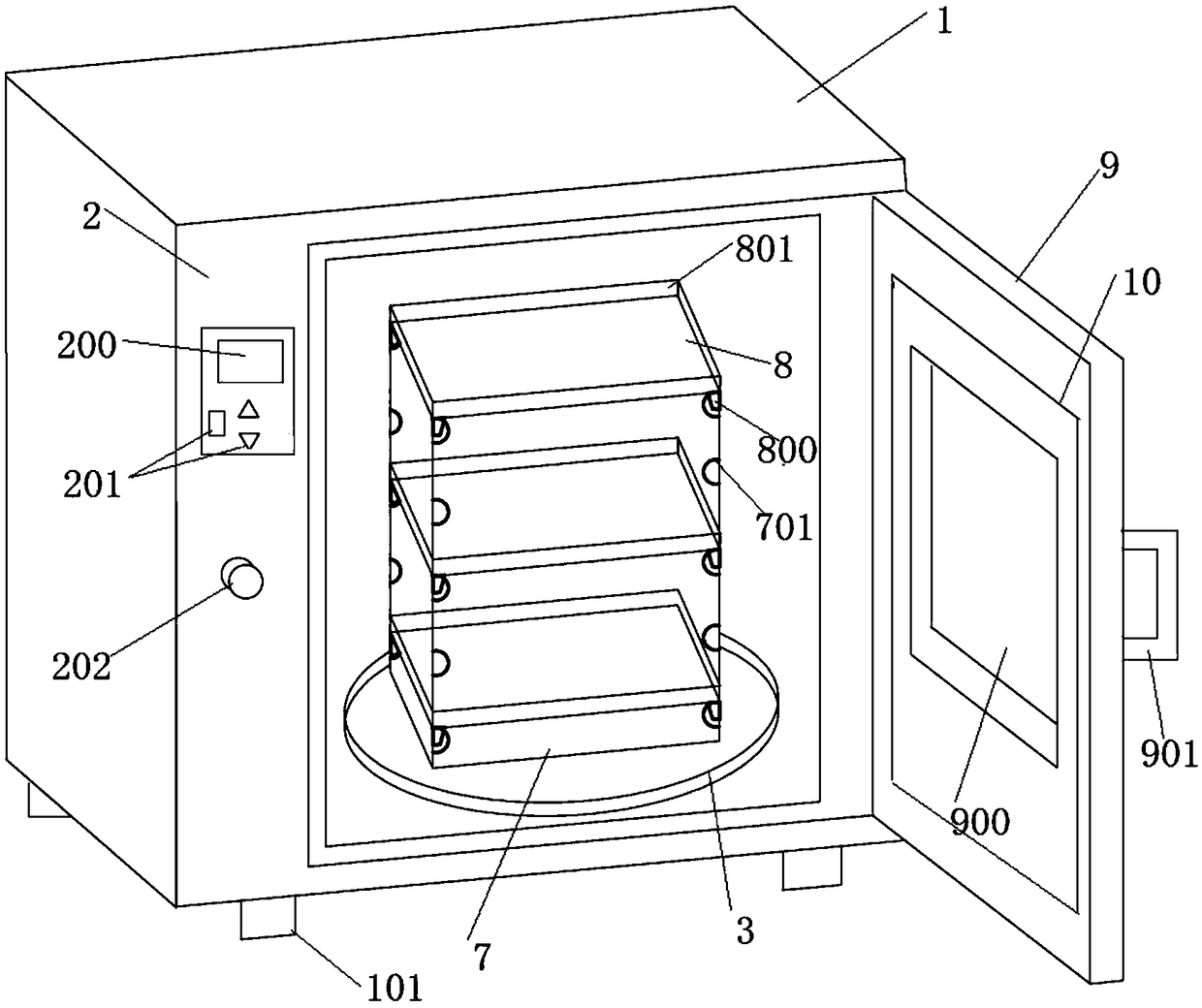

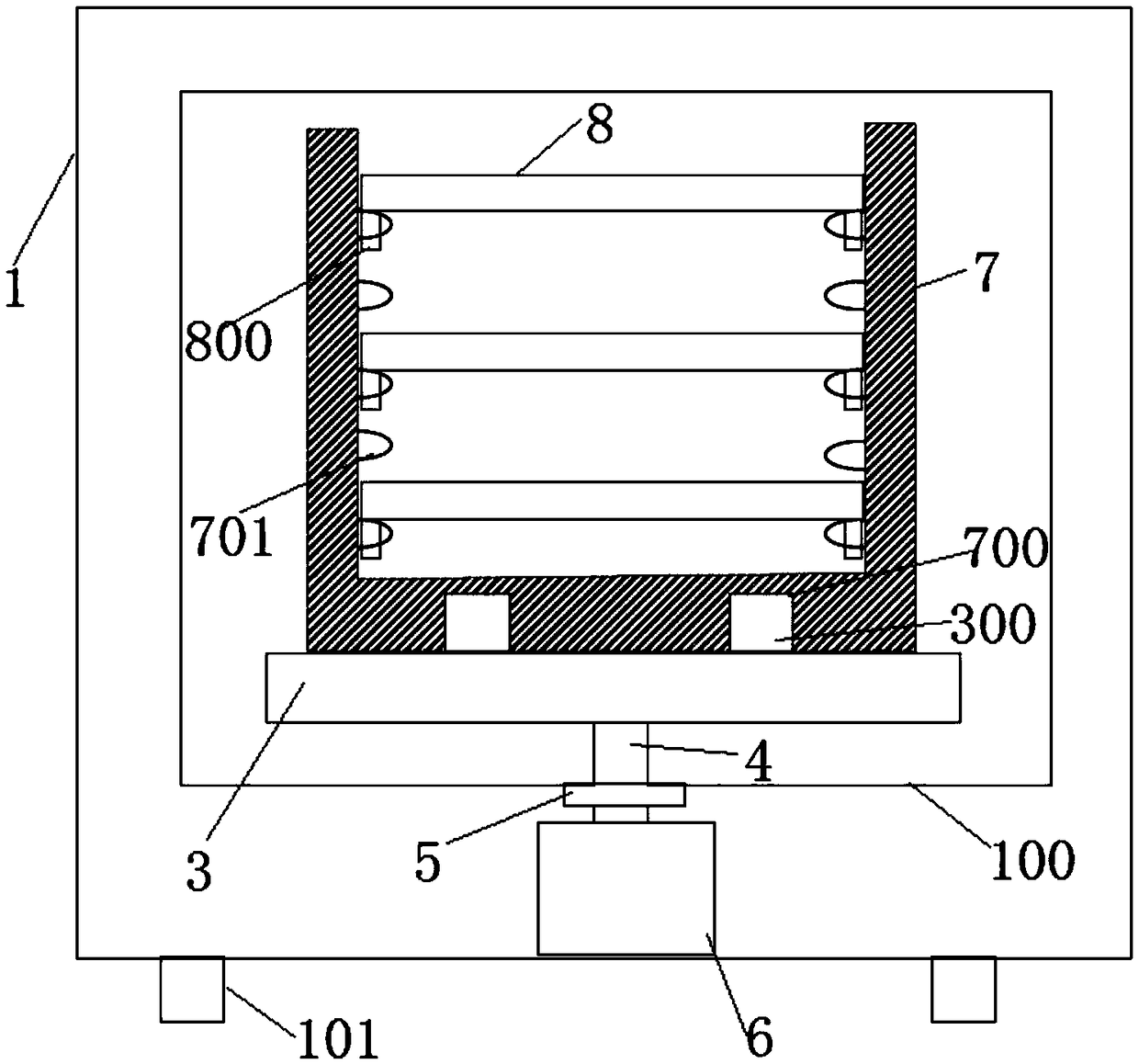

[0020] A heating and drying box that is convenient for taking and placing experimental utensils, comprising a drying box body 1 and a control box 2 arranged on one side of the drying box body 1, a bottom plate 100 is arranged inside the drying box body 1, and a bottom plate 100 is located at the center of the upper surface of the bottom plate 100 A rotating disc 3 is provided, and a rotating shaft 4 is fixed on the bottom of the rotating disc 3, and the rotating shaft 4 is fixed on the middle part of the bottom plate 100 through a sealed bearing 5, and a drive motor 6 is arranged in the cavity between the bottom plate 100 and the lower side of the drying box body 1 , the output shaft of the driving motor 6 is connected with the rotating shaft 4; the upper part of the rotating disk 3 is connected with a turret 7, and the rotating disk 3 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap