Wearing fault diagnosis method of automobile engine bushing

A technology for automobile engine and wear faults, which is applied in engine testing, mechanical component testing, and machine/structural component testing, etc. It can solve problems such as insufficient feature quantities, long training time for classification networks, and insufficient fault samples. Achieve the effect of effective feature extraction and high effective accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The method for diagnosing the bearing bush wear fault of the automobile engine provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

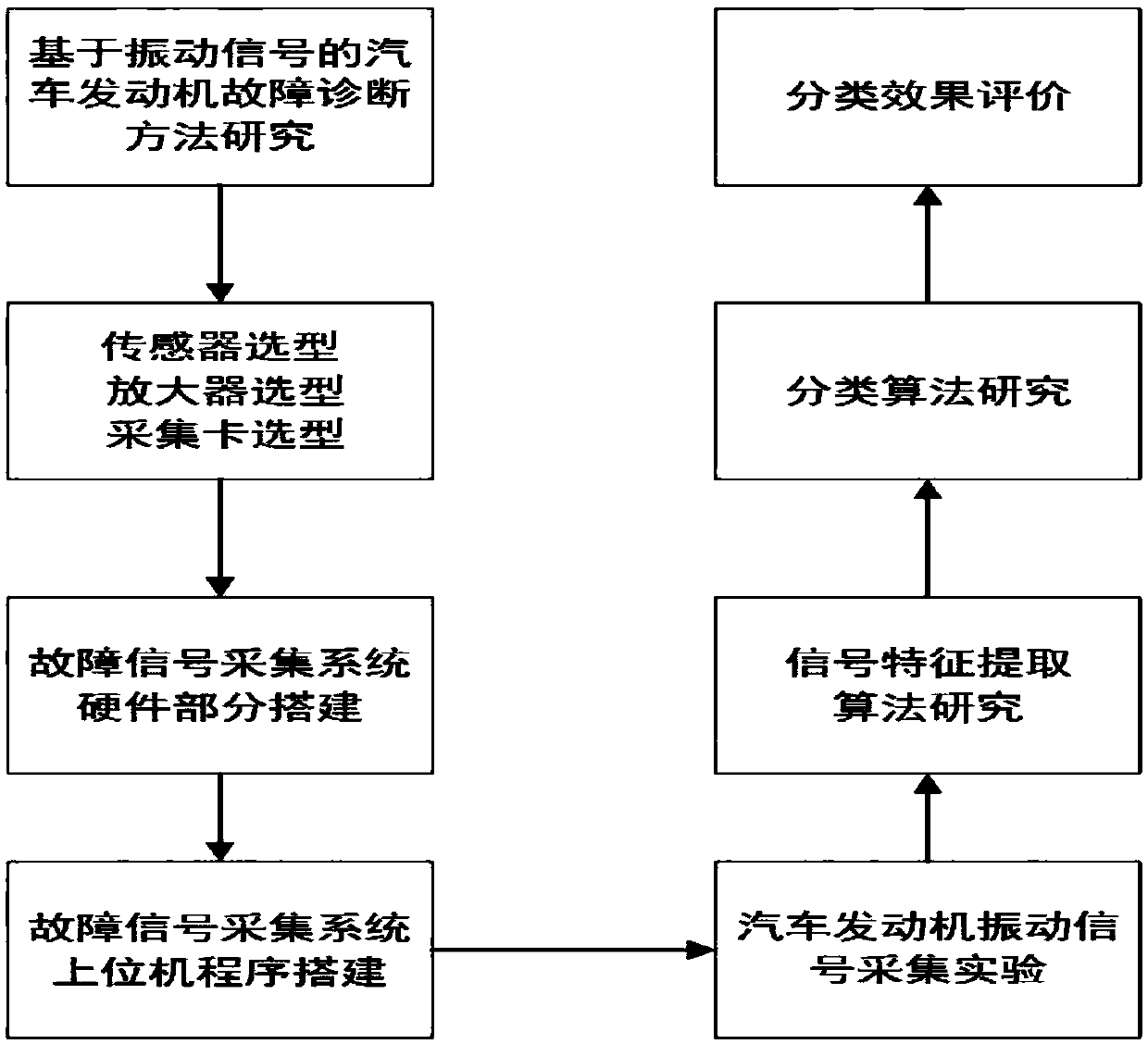

[0040] like figure 1 As shown, the automobile engine fault diagnosis method provided by the present invention includes the following steps carried out in order:

[0041] 1) Carry out the feature extraction of the time-domain statistics of the vibration signal under normal and bearing pad wear conditions of the automobile engine:

[0042] First establish the vibration signal acquisition system:

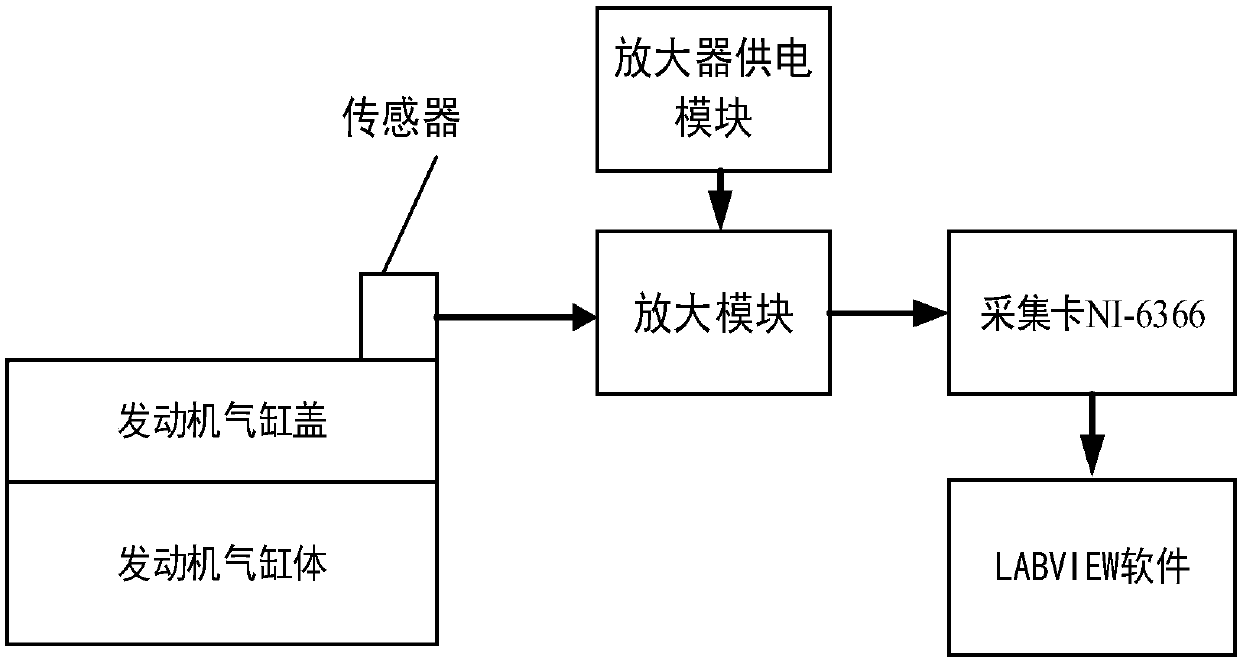

[0043] like figure 2 As shown, the present invention utilizes a vibration signal acquisition system composed of a sensor, a signal amplification module, a power supply module and a data acquisition card to collect vibration signals under two different working conditions of the automobile engine, and realizes the collection by writing a program with the LabVie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com