Tool holder

A tool holder and frame technology, applied in the field of C-shaped tool holders, can solve problems such as excessive bending angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

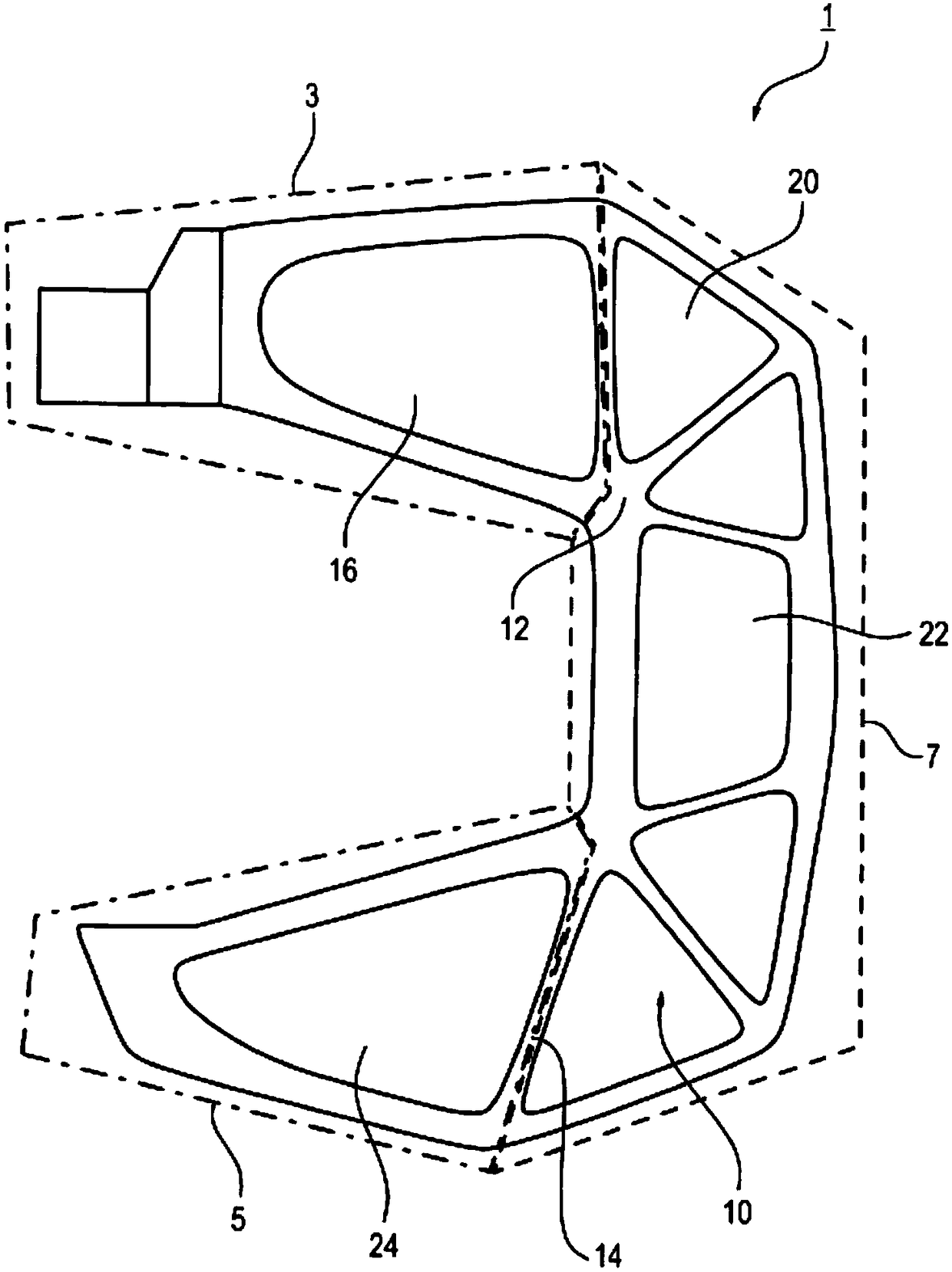

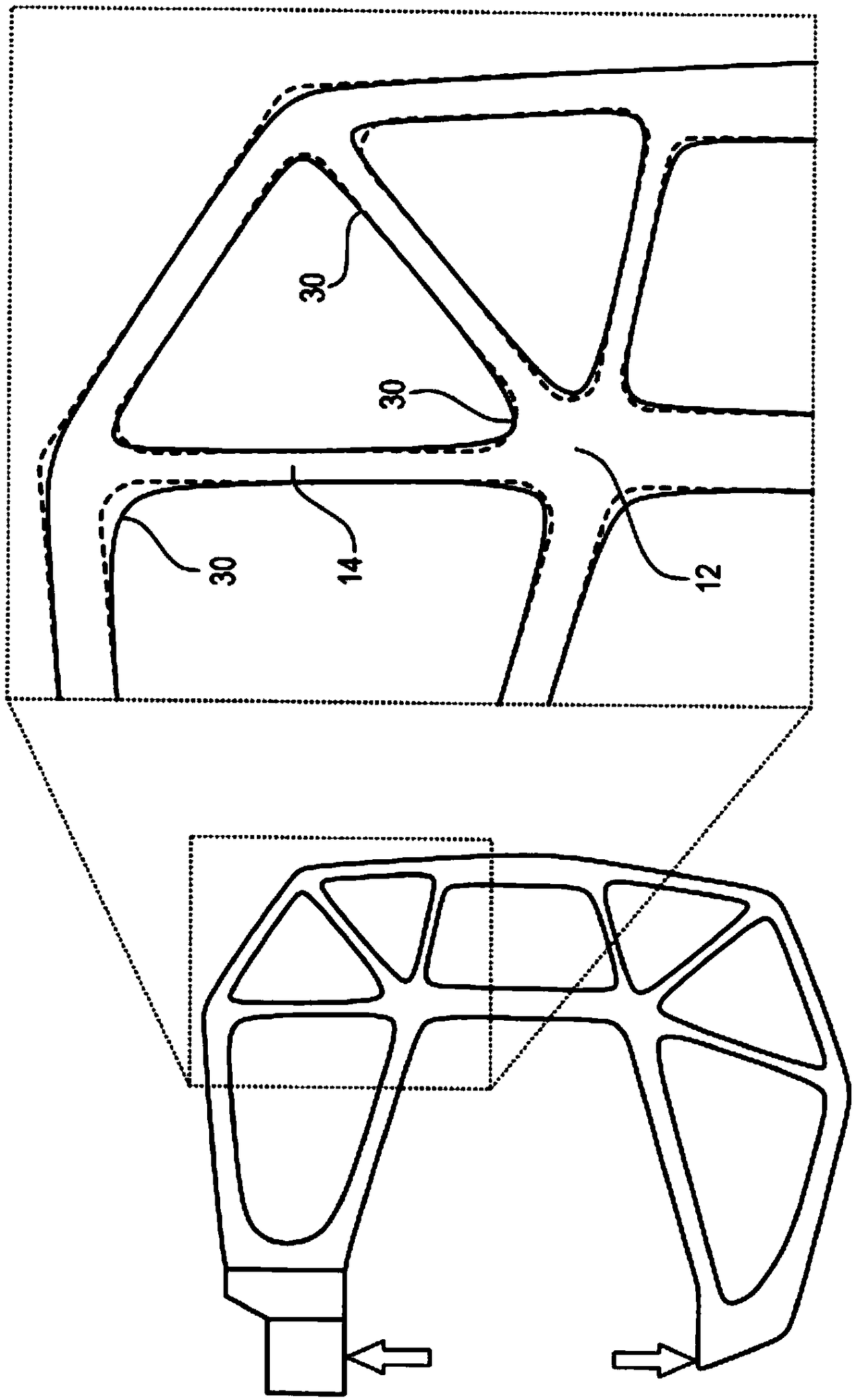

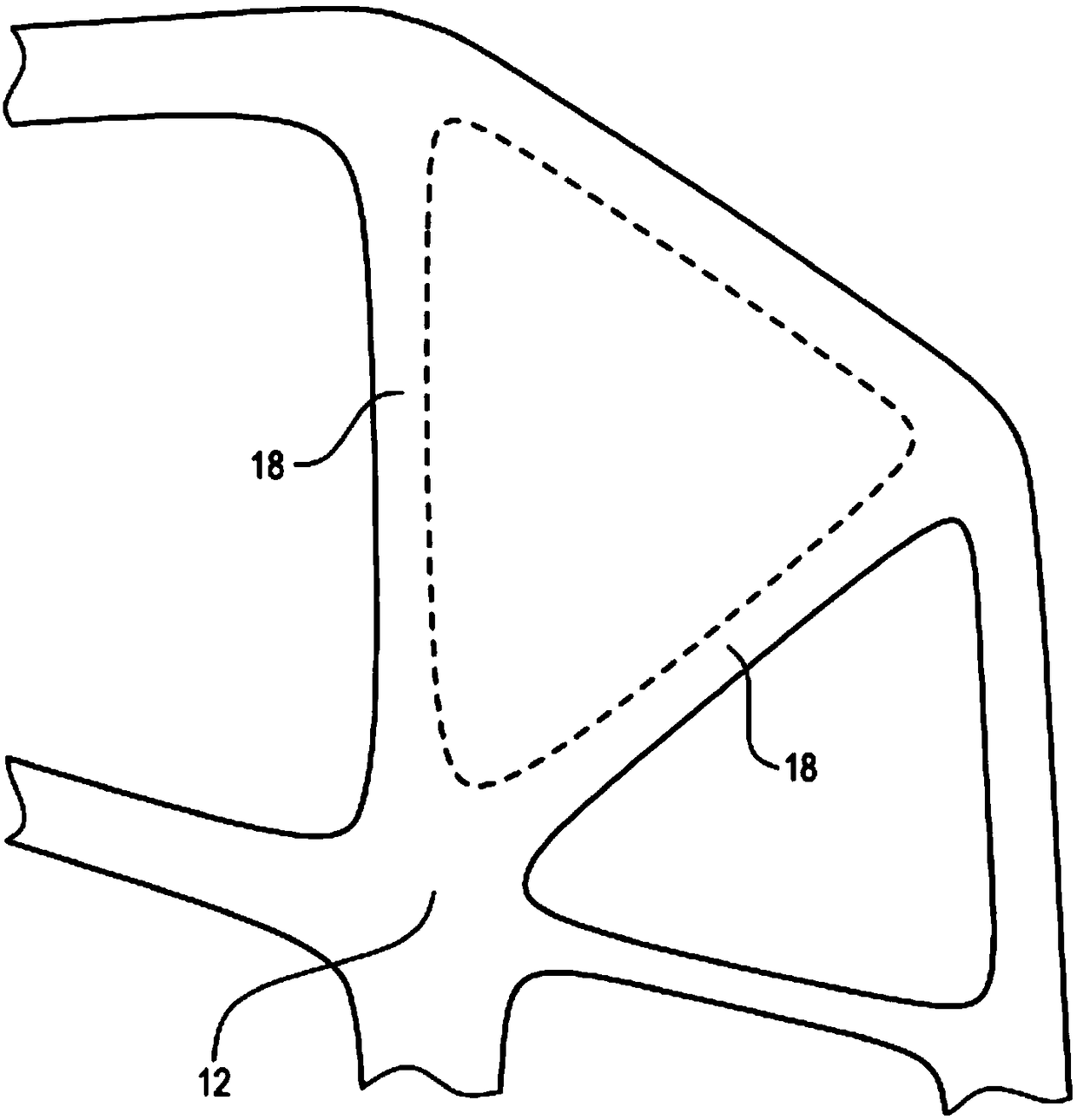

[0049] According to a preferred embodiment, the present invention discloses in a schematic side view such as figure 1 C-shaped tool holder 1 shown. They are generally known for their use in rivet fixing devices or riveting tools, for example. They are included in figure 1 It extends horizontally and passes through the connecting leg 7 ( figure 1 Dotted line in) a first leg 3 and a second leg 5 connected to each other (see figure 1 Dotted line in).

[0050] The first leg 3 and the second leg 5 and the connecting leg 7 are composed of an integral frame structure 10. In the frame structure 10, they are integral with each other and there are no leg modules that are connected or connectable. In this case, the whole means that the frame structure 10 forms a continuous whole and cannot be divided into its various parts without destroying it. Correspondingly, the leg portions 3, 5, 7 are not connected to each other by force fit, friction or surface bonding connection elements.

[0051] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap