Liquid spraying device

A spraying device and a technology of a liquid spraying head, which is applied in printing and other directions, and can solve the problems such as easy maintenance of waste liquid absorbing parts and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

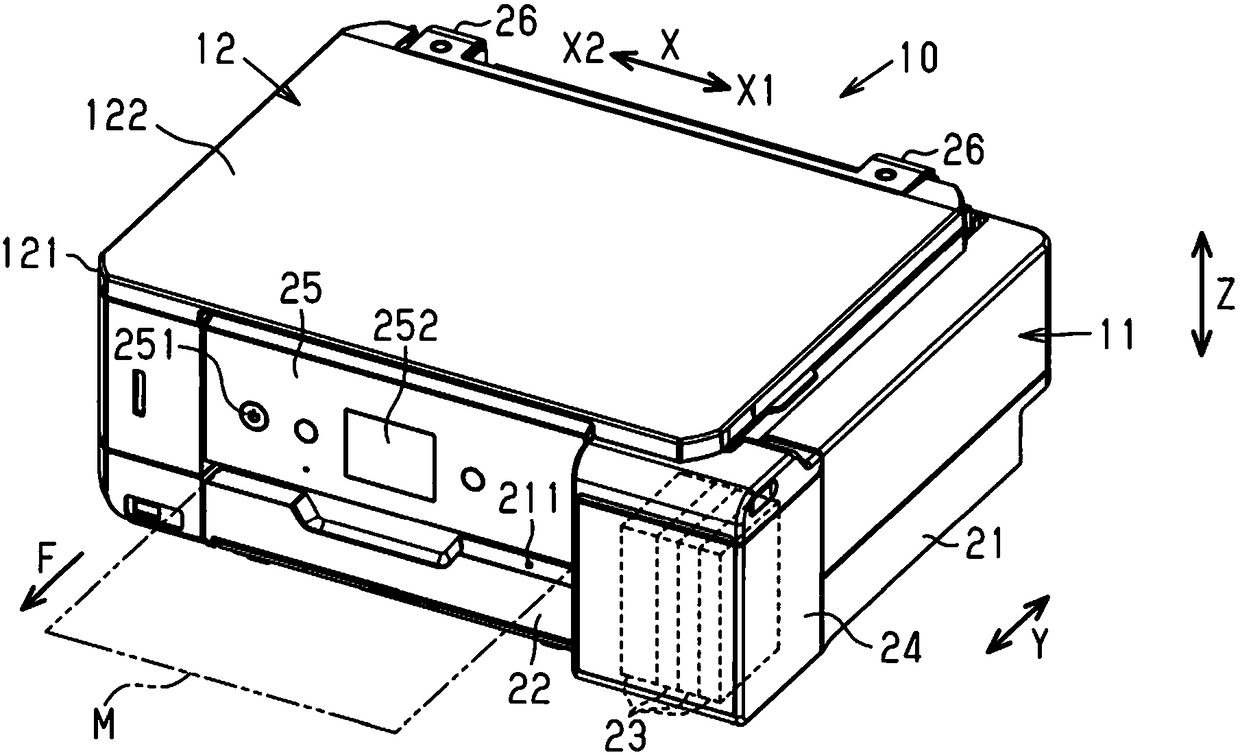

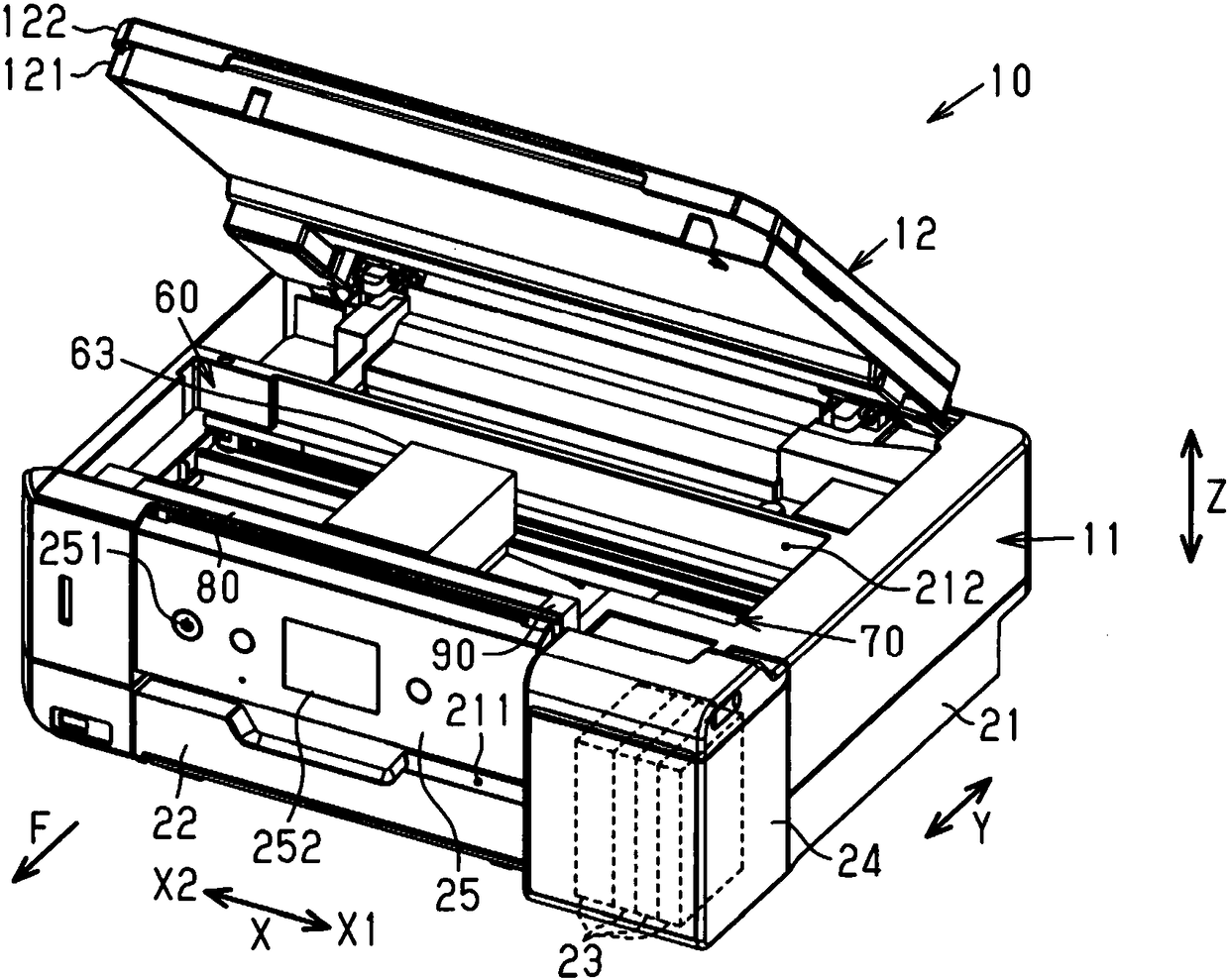

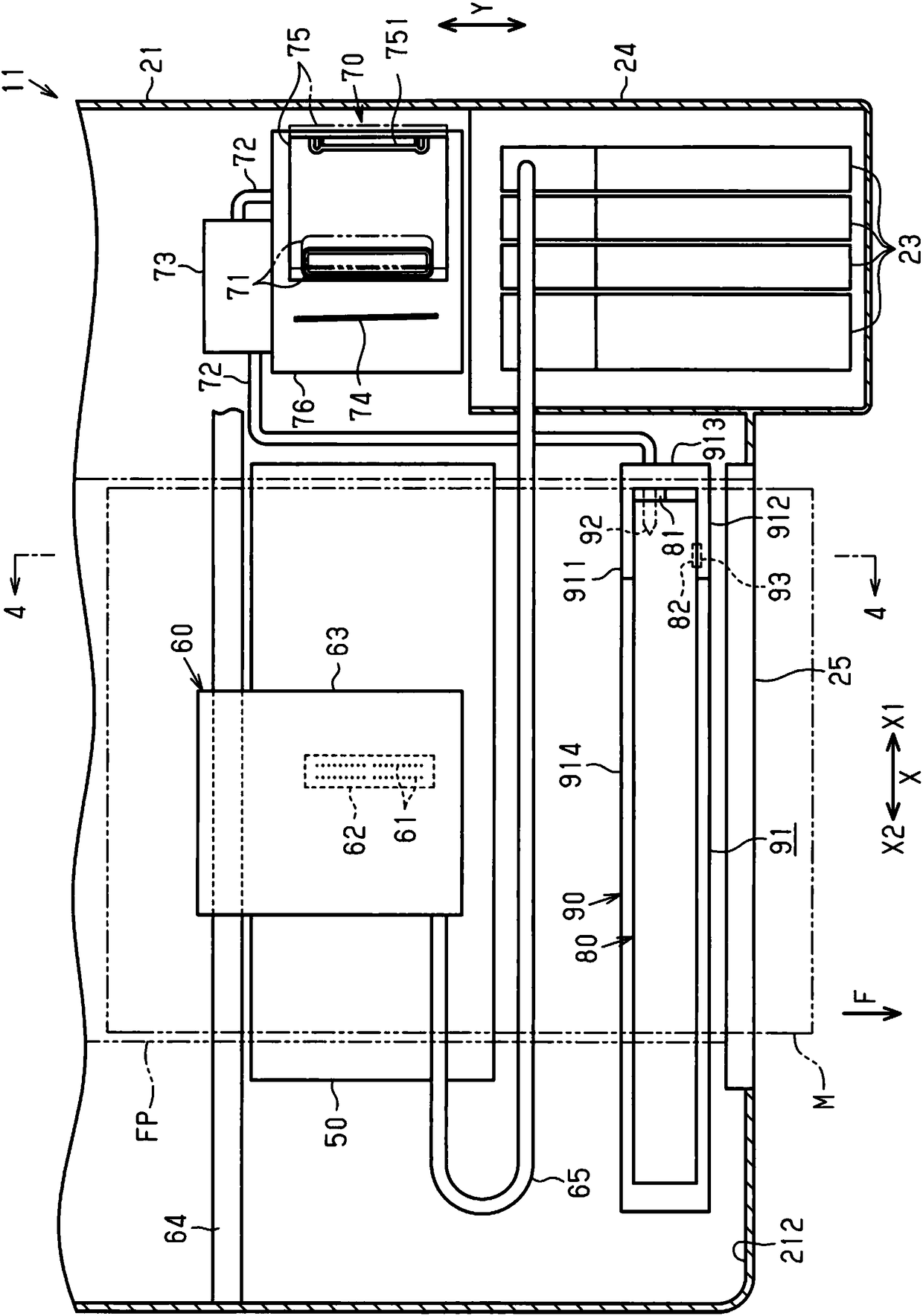

[0028] Hereinafter, an embodiment of a multifunction peripheral including a liquid ejecting device will be described with reference to the drawings. The liquid ejecting device of the present embodiment is an inkjet printer that prints characters or images by ejecting ink, which is an example of a liquid, onto a medium such as paper. In addition, in the following description, in order to make the description easy to understand, illustration of some components is omitted from the drawings, or the types of hatched lines are made the same.

[0029] Such as figure 1 As shown, the multifunction peripheral 10 includes: a liquid ejecting device 11 that ejects liquid onto a medium M; and a reading device 12 that reads characters or images written on a document. In this embodiment, when the multifunction peripheral 10 is placed on a horizontal plane, the width direction of the multifunction peripheral 10 is referred to as the "scanning direction X", and the front and rear directions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com