Garbage can with internal automatic compacting function

A garbage can and automatic technology, applied in the direction of garbage cans, garbage collection, household appliances, etc., can solve the problems of garbage scattered on the ground, high frequency of replacement, knocked down garbage cans, etc., to achieve convenient garbage placement, good effect, and improved stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

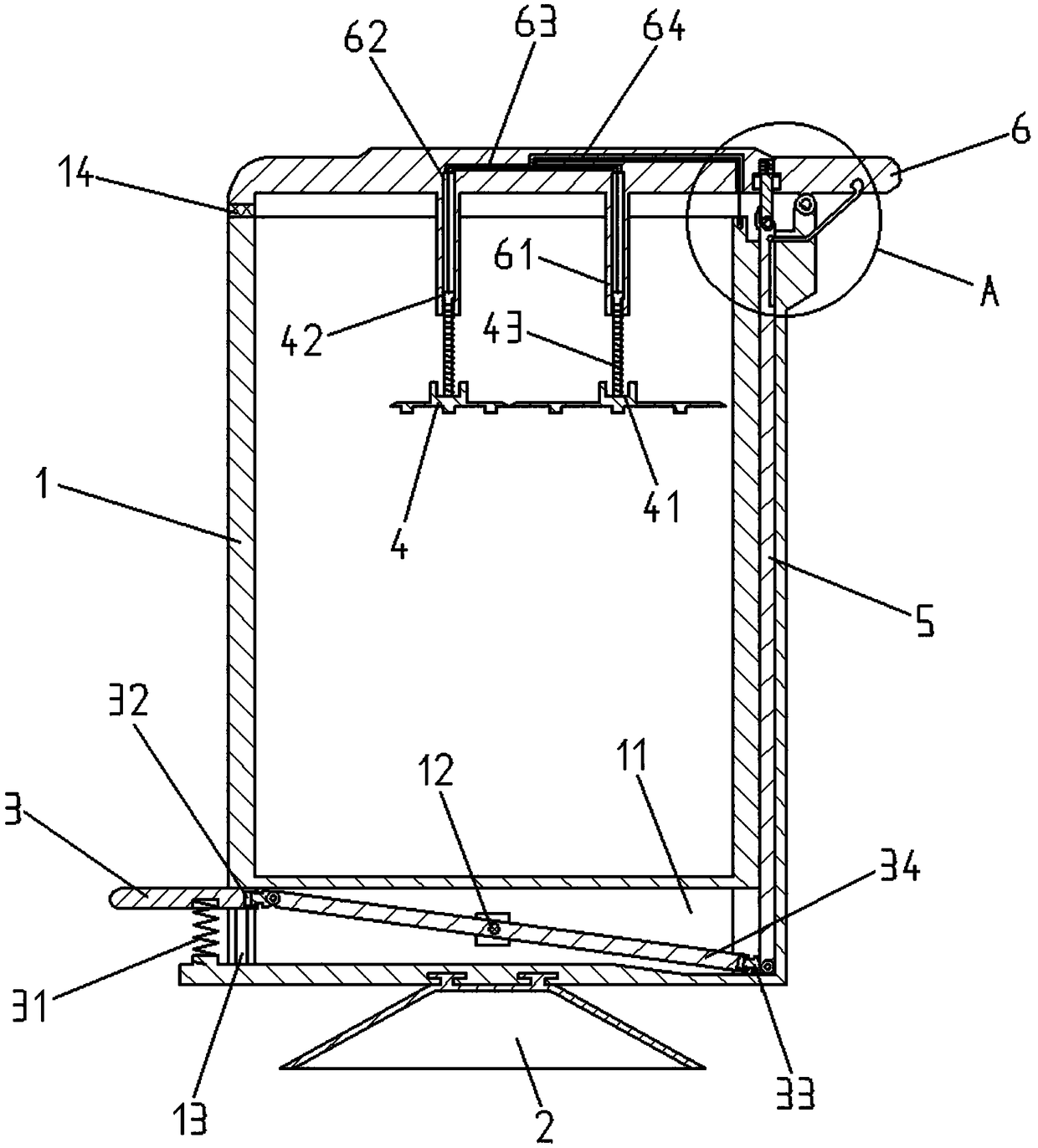

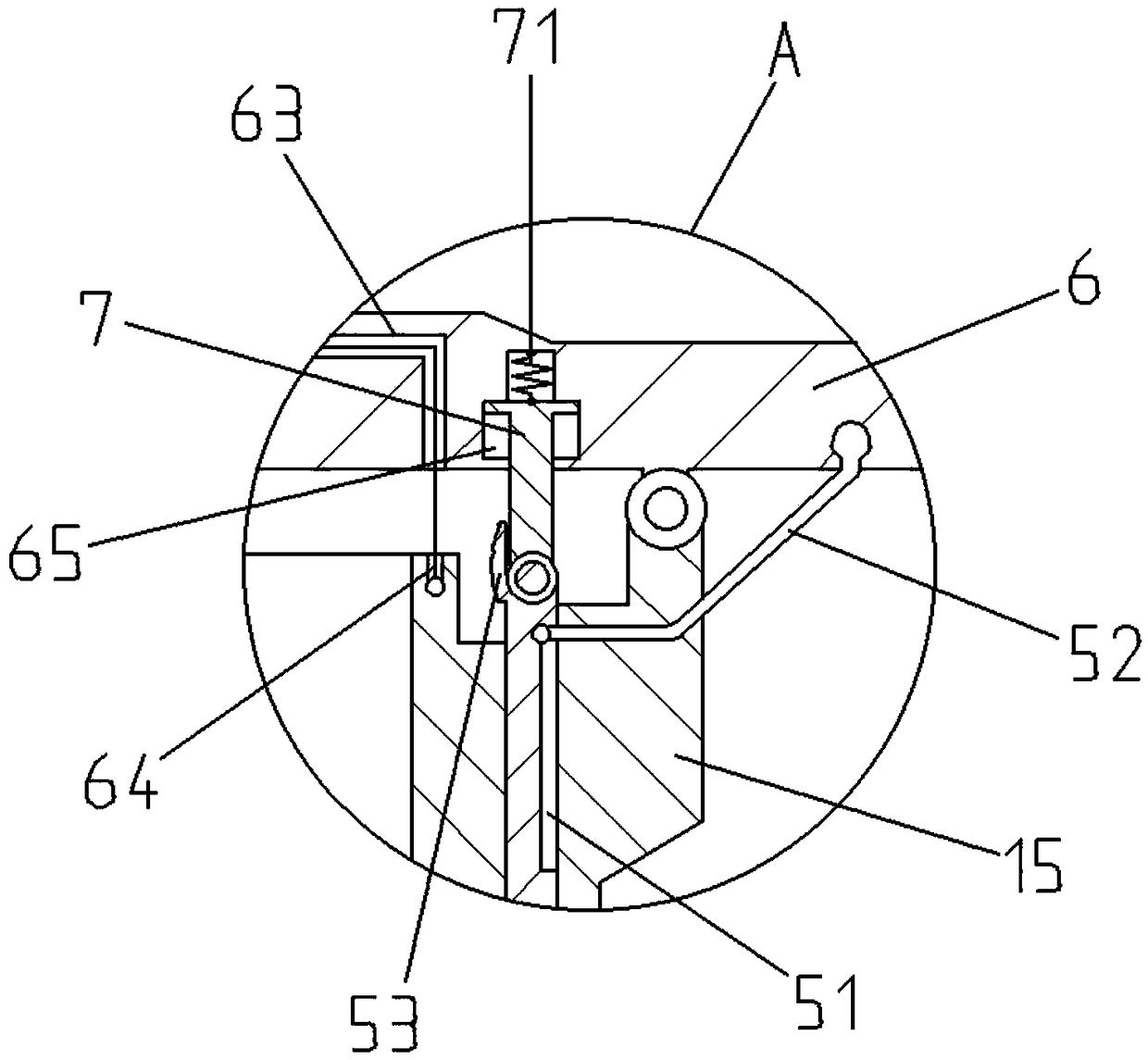

[0032] The following is a description of Embodiment 1.

[0033] Such as Figure 1 to Figure 5 As shown in the figure, an internal automatic compression garbage can includes a barrel body 1, an installation cavity 11, a lever fulcrum 12, a stepping slide rail 13, a shockproof pad 14, a protective fulcrum block 15, a jack rod accommodation groove 16, and a bucket bottom plate 17 , bag installation groove 18, soft sucker 2, stepping plate 3, stepping spring 31, adaptive front sliding chamber 32, adaptive slider 33, start lever 34, adaptive rear sliding chamber 35, compacting plate 4, limiting Position slot 41, T-shaped slide bar 42, compaction spring 43, anti-skid protrusion 44, start ejector rod 5, rope body accommodation groove 51, pull cover rope 52, steel wire support block 53, protective cover 6, compaction positioning rod 61. Positioning sliding cavity 62, steel wire channel 63, tensioning steel wire 64, supporting sliding cavity 65, starting support rod 7, adaptive spring...

Embodiment 2

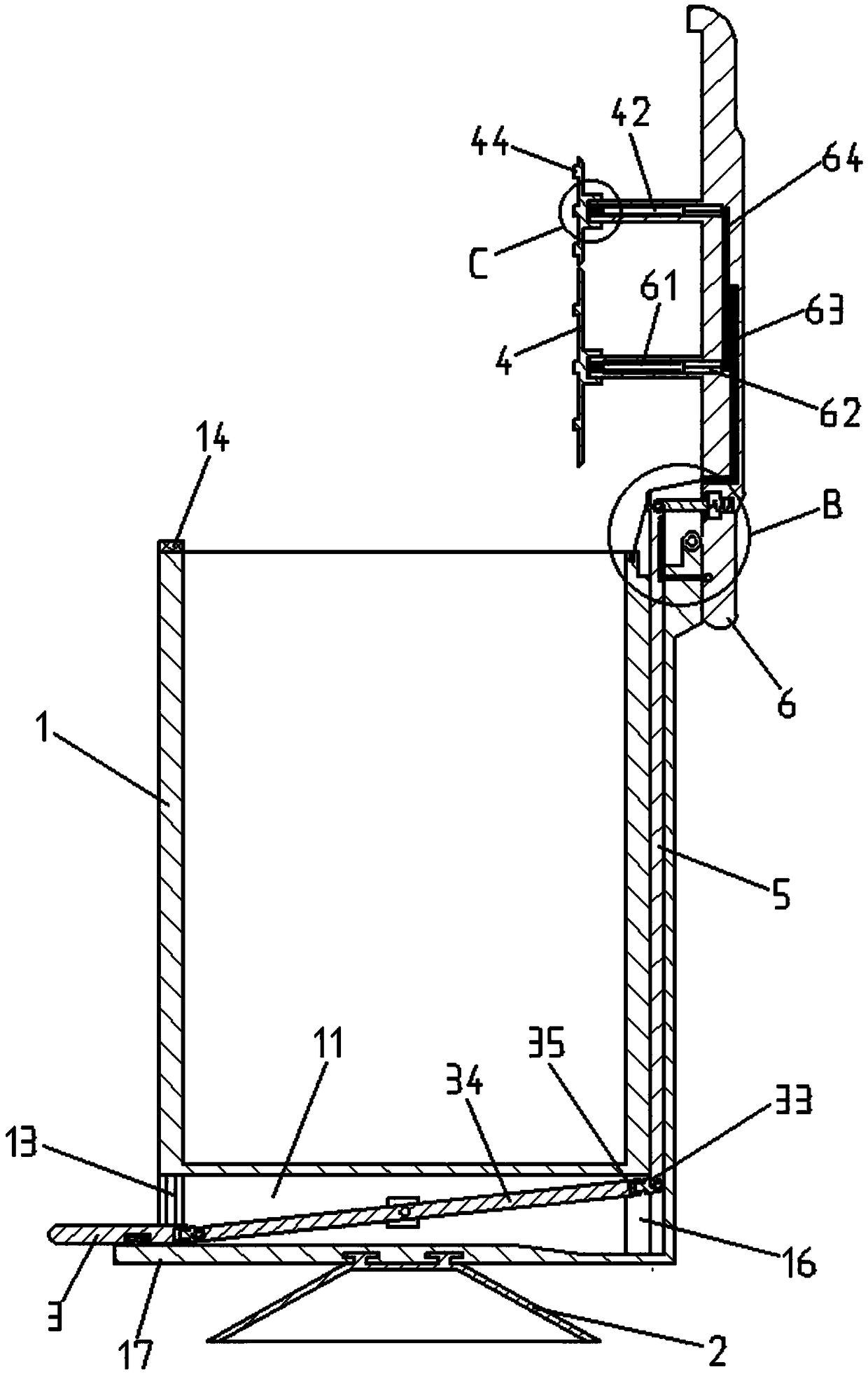

[0039] The following is a description of Embodiment 2.

[0040] In embodiment 2, for the same structure as embodiment 1, give the same symbol, omit the same description, embodiment 2 has made improvement on the basis of embodiment 1, as Figure 6 As shown, the length of the compacting positioning rod 61 is reduced, the T-shaped sliding rod 42 adopts a telescopic rod 8, and the top rod body of the telescopic rod 8 is set in a T shape and is slidably arranged in the positioning sliding cavity 62, The tension steel wire 64 passes through the inside of the telescopic rod 8 and is connected with the top of the compacting plate 4 .

[0041] The advantage of this embodiment is that the shrinkage length of the compacting plate 4 can be made smaller, which facilitates opening the protective cover 6 and can more effectively adapt to the height of the garbage in the bucket body 1 .

[0042] When positioning the device, select the pre-fixed position of the trash can, and press the soft s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com