Yarn reeling and tensioning device

A tensioning device and yarn technology, applied in the textile field, can solve the problem that the yarn winding tensioning device cannot be adjusted as needed, and achieve the effects of improving the drawing quality, efficiently removing impurities and improving the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

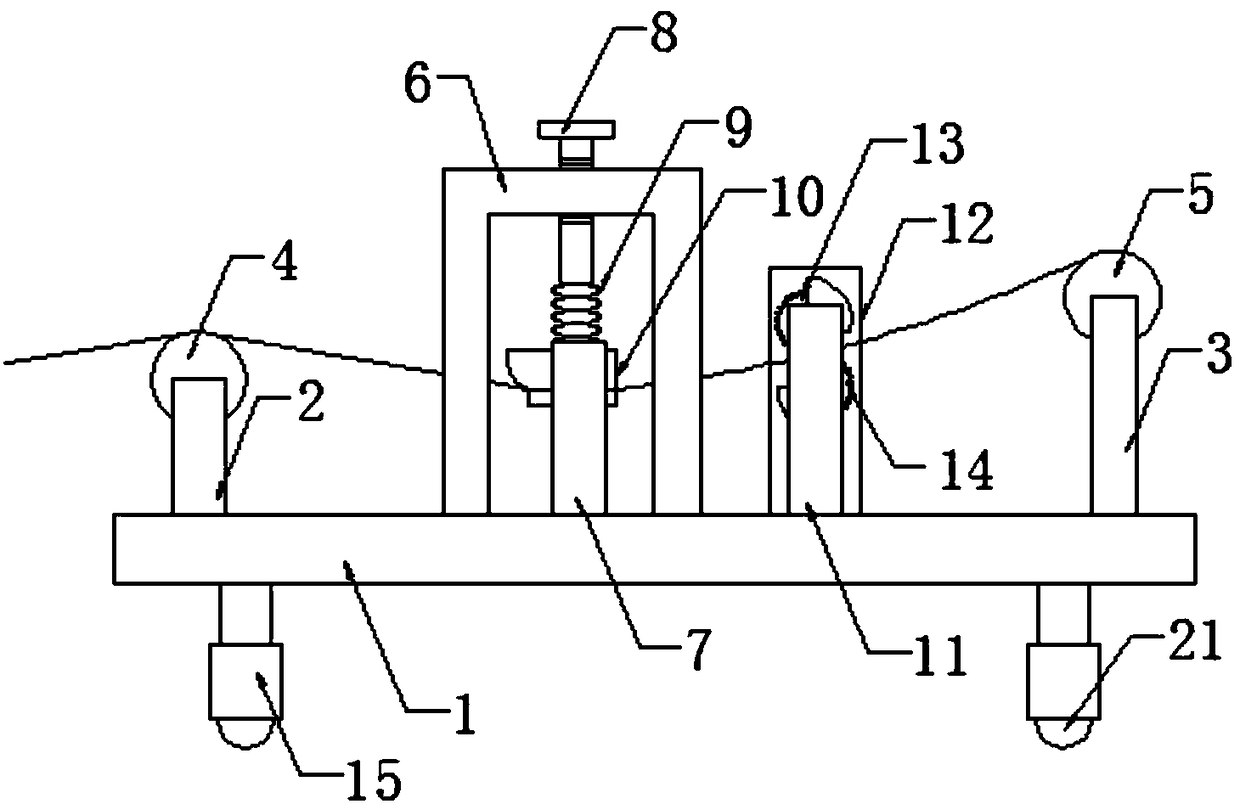

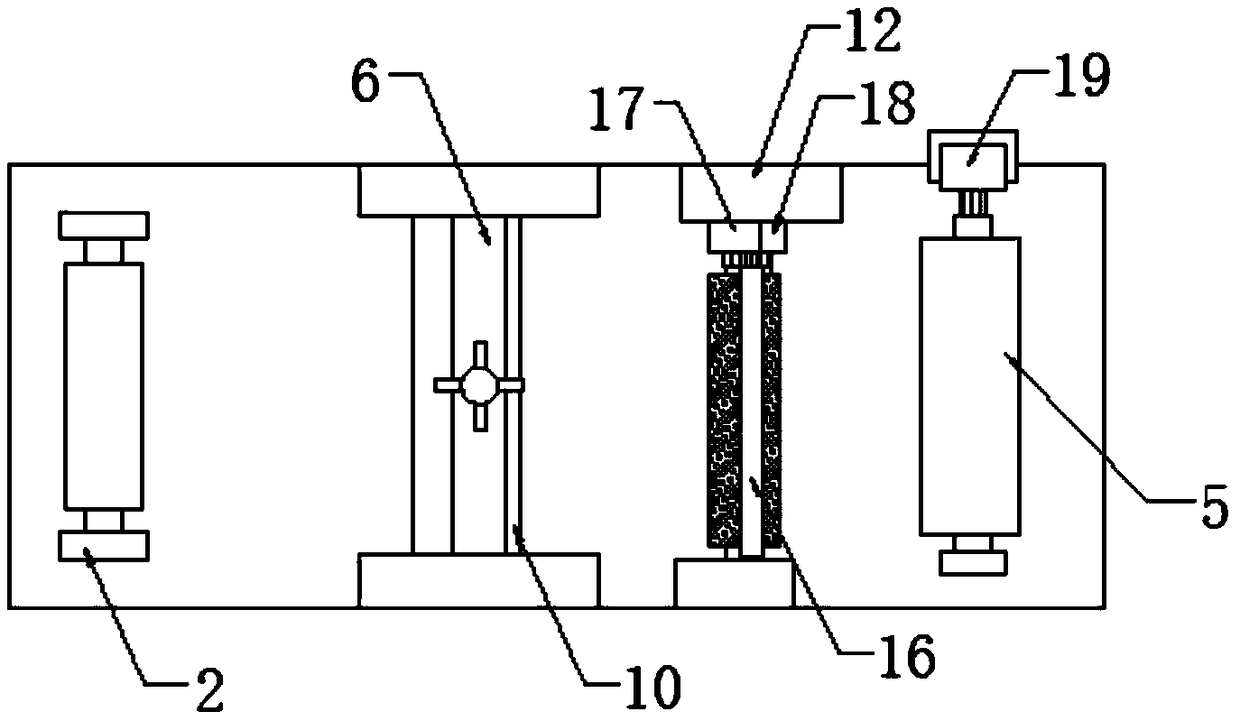

[0023] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

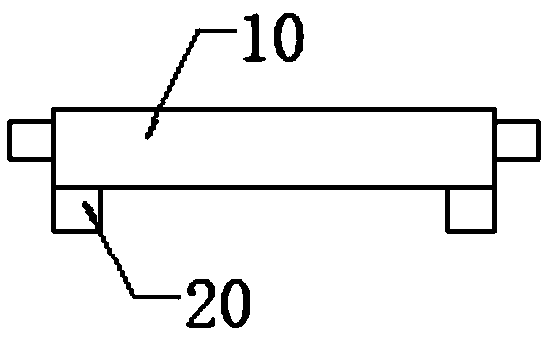

[0024] like Figure 1-5 As shown, a yarn winding and tensioning device of the present invention includes a base 1, two ends of the base 1 are respectively provided with two first support rods 2 and two second support rods 3, and the two first support rods 2 The input roller 4 is engaged with the top of the top, and the top of one of the second support rods 3 is provided with a fixed plate, and a servo motor 19 is installed on the top of the fixed plate, and the output end of the servo motor 19 is connected with one end of the winding roller 5 through transmission. The other end of the winding roller 5 is engaged with the top of another second support rod 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com