Four-way elastic hydrolysis-resistant super soft protein synthetic leather

A synthetic leather and hydrolysis-resistant technology, which is applied in textiles and papermaking, can solve the problems of limited development and unsatisfactory hydrolysis resistance of synthetic leather, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

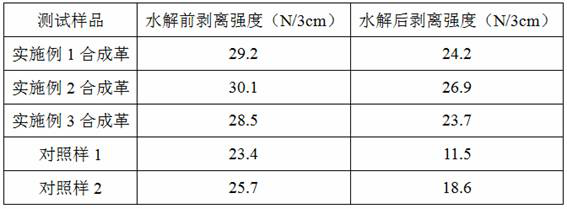

Examples

preparation example Construction

[0016] The raw materials for the preparation of the supersoft hydrolysis-resistant polyurethane resin include, in parts by weight: 7-10 parts of diisocyanate, 15-20 parts of polyester polyol, 3-8 parts of modified viscose fiber, and 2-5 parts of chain extender , DMF 60-70 parts; its preparation method is to heat polyester polyol, modified viscose fiber, chain extender and part of DMF to 50-60 ° C, stir and dissolve, then add diisocyanate, and heat up to 80-110°C, heat preservation reaction for 1-2h, then lower the temperature to 50-60°C, add the remaining DMF dropwise to adjust the viscosity, and stop the reaction after the viscosity is suitable.

[0017] Wherein, the modified viscose fiber is soaked in 50°C and 10wt% sodium hydroxide solution for 30 minutes, washed with water until neutral, and dried to obtain pretreated viscose fiber; then palmitic acid, Mix acid anhydride with concentrated sulfuric acid, add pretreated viscose fiber after heating to 80°C, stir and heat to 1...

Embodiment 1

[0028] A four-way elastic hydrolysis-resistant supersoft protein synthetic leather, which includes a wet-laid base and a veneer pasted on the wet-laid base, wherein the wet-laid base is made of wet-laid slurry coated on the base cloth The base fabric is a four-way elastic fabric, and the wet-process slurry is made of the following raw materials in parts by weight: 100 parts of supersoft hydrolysis-resistant polyurethane resin, 50 parts of DMF, 2 parts of color paste, and 3 parts of cell regulator , 0.2 part of waterproofing agent.

[0029] The raw materials for the preparation of the supersoft hydrolysis-resistant polyurethane resin include by weight: 10 parts of diisocyanate, 15 parts of polyester polyol, 4 parts of modified viscose fiber, 4 parts of chain extender, and 67 parts of DMF;

[0030] Wherein, the modified viscose fiber is soaked in 50°C and 10wt% sodium hydroxide solution for 30 minutes, washed with water until neutral, and dried to obtain pretreated viscose fiber...

Embodiment 2

[0033] A four-way elastic hydrolysis-resistant supersoft protein synthetic leather, which includes a wet-laid base and a veneer pasted on the wet-laid base, wherein the wet-laid base is made of wet-laid slurry coated on the base cloth The base fabric is a four-way elastic fabric, and the wet-process slurry is made of the following raw materials in parts by weight: 100 parts of supersoft hydrolysis-resistant polyurethane resin, 56 parts of DMF, 2 parts of color paste, and 4 parts of cell regulator , 0.3 part of waterproofing agent.

[0034] The raw materials for the preparation of the supersoft hydrolysis-resistant polyurethane resin include, in parts by weight: 8 parts of diisocyanate, 16 parts of polyester polyol, 3 parts of modified viscose fiber, 5 parts of chain extender, and 68 parts of DMF;

[0035] Wherein, the modified viscose fiber is soaked in 50°C and 10wt% sodium hydroxide solution for 30 minutes, washed with water until neutral, and dried to obtain pretreated visc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com