Halogen-free flame-retardant water-resistant weather-resistant PC composite material and application thereof in electrical field

A composite material and compound technology, applied in the field of polycarbonate, can solve the problems of poor notched impact and low temperature toughness, low flame retardant performance, poor processing performance, etc., to improve strength and toughness, improve impact strength, improve Compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

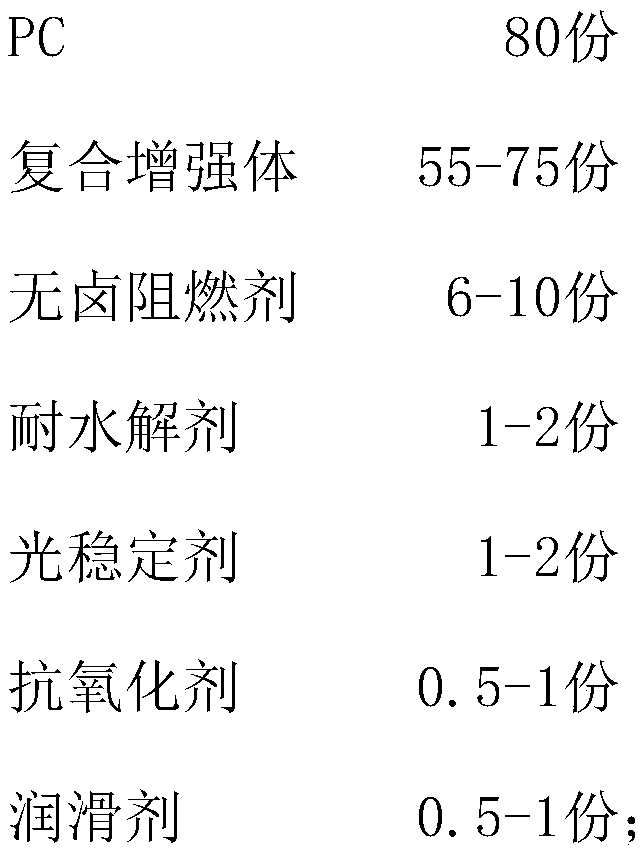

[0031] A halogen-free flame-retardant, water-resistant and weather-resistant PC composite material, comprising the following raw materials in parts by weight:

[0032]

[0033] The composite reinforcement is prepared by dispersing and mixing 25 parts of glass fiber, 20 parts of nanocellulose and 20 parts of PC

[0034] Wherein, the preparation method of the composite reinforcement includes the following steps;

[0035] A. Add 25 parts of glass fibers and 20 parts of nanocellulose in 1000 parts by weight of water, then carry out ultrasonic dispersion for 3 hours, centrifugally wash and freeze-dry to obtain the first mixture;

[0036] B. Take 100 parts by weight of an organic solvent to dissolve 20 parts by weight of PC to form a mixed solution, add the first mixed material to the mixed solution, and ultrasonically disperse for 1.5 hours to obtain a suspension;

[0037] C. Spray drying the suspension to obtain the composite reinforcement.

[0038] Wherein, the glass fiber h...

Embodiment 2

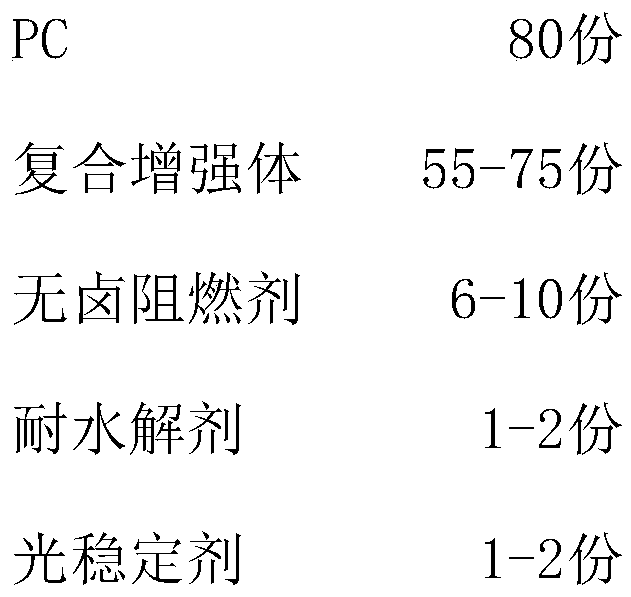

[0050] A halogen-free flame-retardant, water-resistant and weather-resistant PC composite material, comprising the following raw materials in parts by weight:

[0051]

[0052] The composite reinforcement is prepared by dispersing and mixing 20 parts of glass fiber, 15 parts of nanocellulose and 20 parts of PC

[0053] Wherein, the preparation method of the composite reinforcement includes the following steps;

[0054] A. Add 20 parts of glass fibers and 15 parts of nanocellulose in 1000 parts by weight of water, then carry out ultrasonic dispersion for 2 hours, centrifugally wash and freeze-dry to obtain the first mixture;

[0055] B. Take 100 parts by weight of an organic solvent to dissolve 20 parts by weight of PC to form a mixed solution, add the first mixed material to the mixed solution, and ultrasonically disperse for 1 hour to obtain a suspension;

[0056]C. Spray drying the suspension to obtain the composite reinforcement.

[0057] Wherein, the glass fiber has a...

Embodiment 3

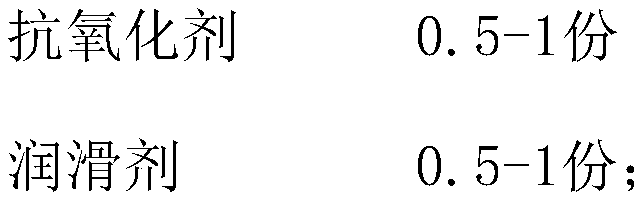

[0069] A halogen-free flame-retardant, water-resistant and weather-resistant PC composite material, comprising the following raw materials in parts by weight:

[0070]

[0071]

[0072] The composite reinforcement is prepared by dispersing and mixing 30 parts of glass fiber, 25 parts of nanocellulose and 20 parts of PC

[0073] Wherein, the preparation method of the composite reinforcement includes the following steps;

[0074] A. Add 25 parts of glass fibers and 20 parts of nanocellulose in 1000 parts by weight of water, then carry out ultrasonic dispersion for 4 hours, centrifugally wash and freeze-dry to obtain the first mixture;

[0075] B. Take 100 parts by weight of an organic solvent to dissolve 20 parts by weight of PC to form a mixed solution, add the first mixed material to the mixed solution, and ultrasonically disperse for 2 hours to obtain a suspension;

[0076] C. Spray drying the suspension to obtain the composite reinforcement.

[0077] Wherein, the gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com