Seam attaching belt laying device and laying method

A laying device and laying method technology, applied in the field of road maintenance equipment, to achieve the effect of simple and convenient adjustment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

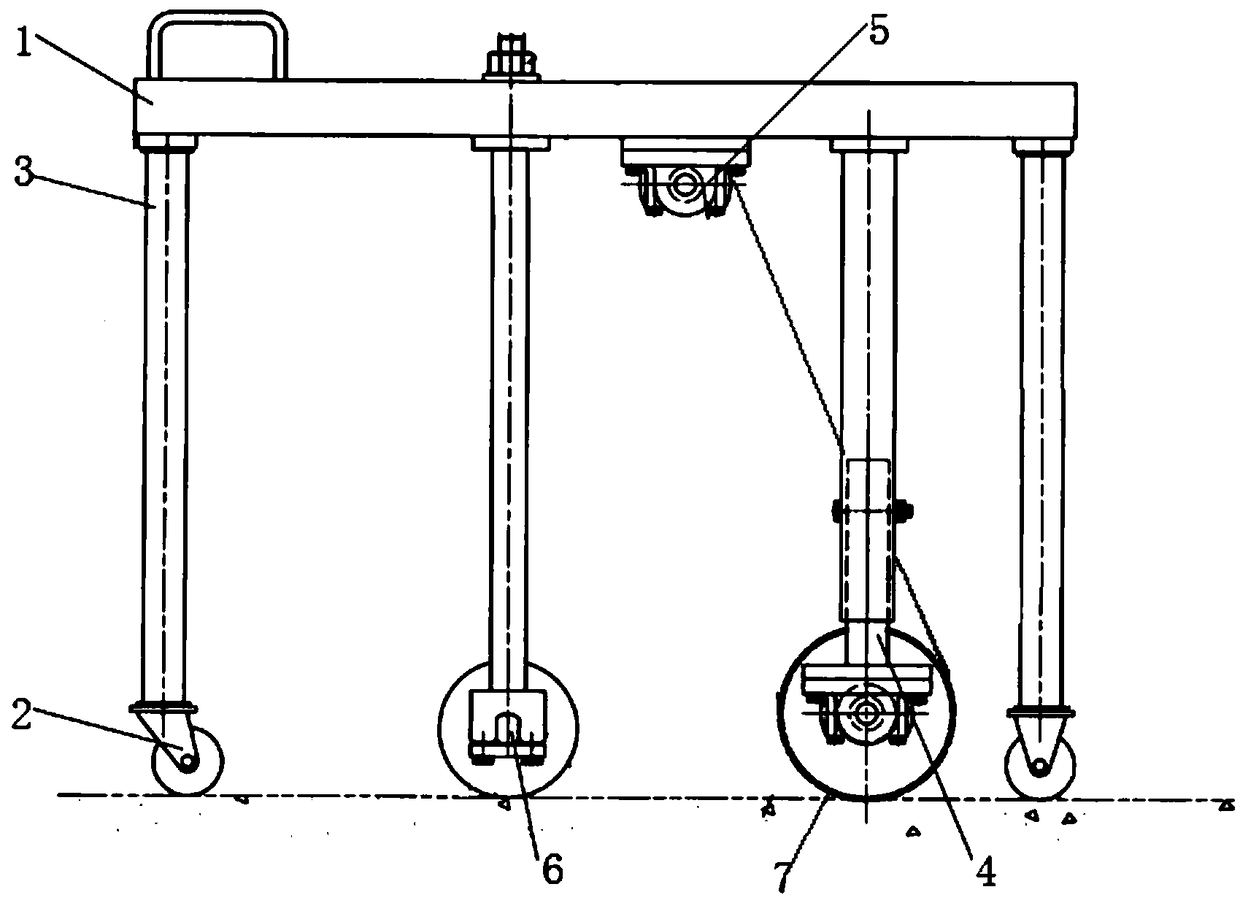

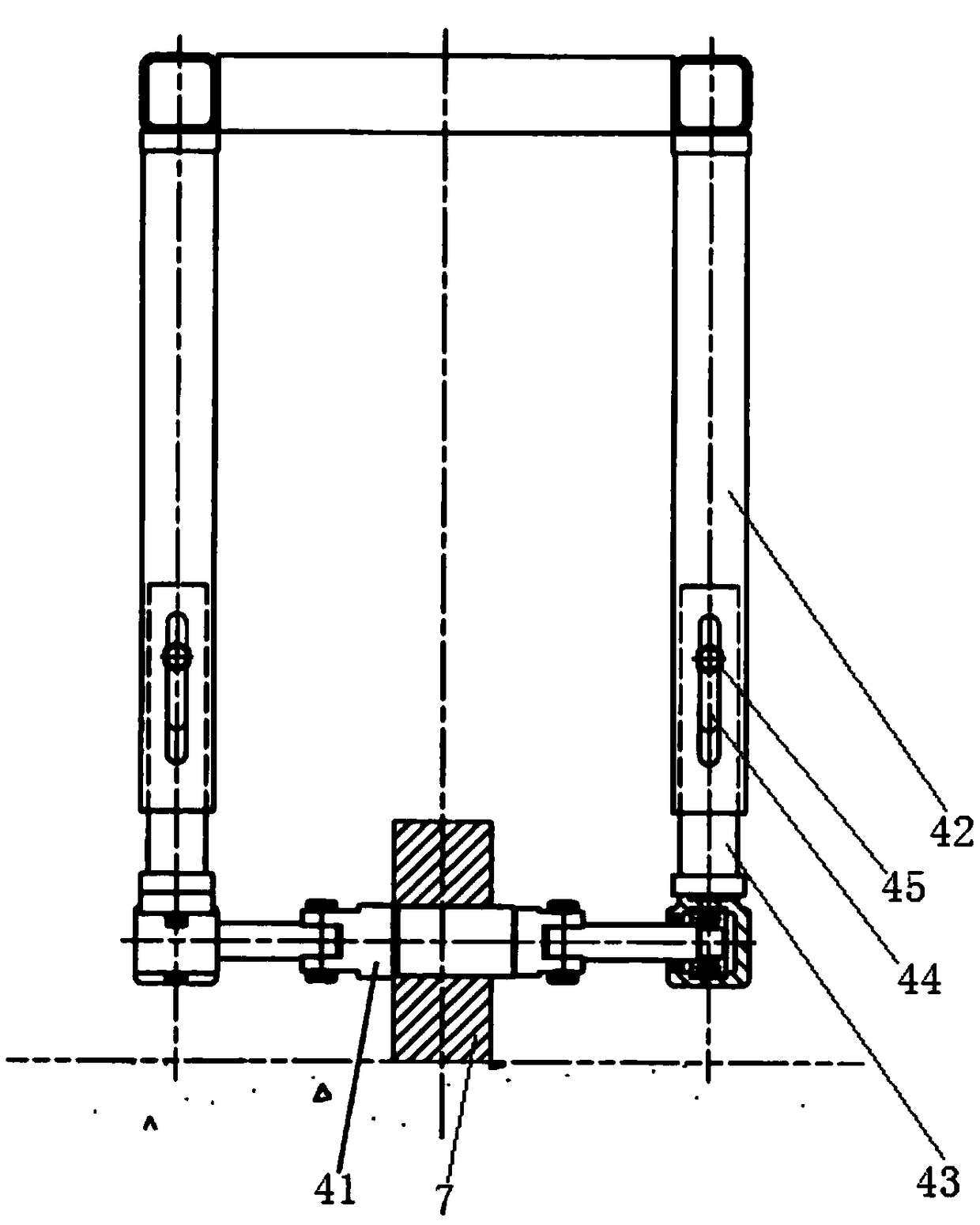

[0111] Such as Figure 1-Figure 6 As shown in , the present invention provides a device for laying seam tape, which includes a frame body 1, on which a leg 3 with castors 2 is installed, and on the frame body 1 is also installed There are a seam belt rotating member 4, a protective film winding member 5 and a pressing member 6;

[0112] A roll-shaped seam tape 7 is supported on the seam tape rotating member 4; the roll-shaped seam tape 7 is continuously attached to the ground under the action of the seam tape rotating member 4;

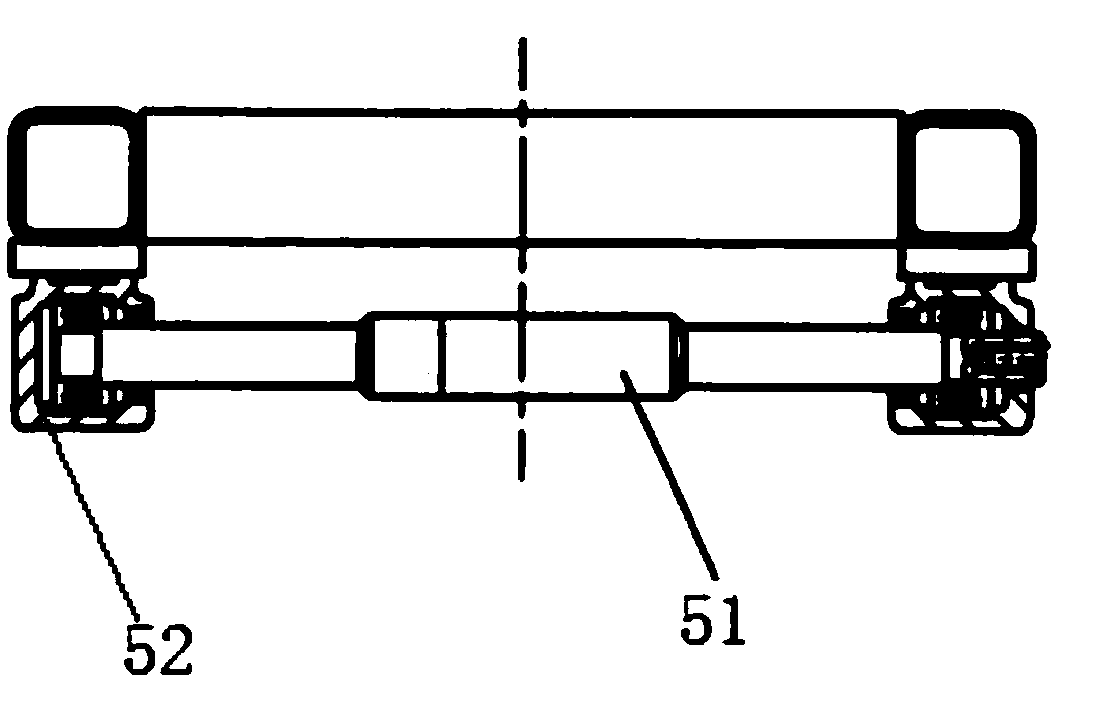

[0113] The protective film winding member 5 is used to wrap the protective film torn off from the pasting surface of the seam tape 7 in real time;

[0114] The pressing member 6 is used to compress the seam tape glued on the road surface, and the rolling force of the rolling wheel 63 is adjustable;

[0115] Two workers operate the seam tape laying device to seam the cracked and gapped road surface. The length of the road surface is 2 kilometers, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com