Elastic Damping Universal Joint

A technology of elastic damping and damper, which is applied in the direction of elastic couplings, couplings, mechanical equipment, etc., can solve the problems of being unable to pull back to the center, unable to suspend the swing speed limit of the shaft, and achieve the effect of suppressing excessive speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

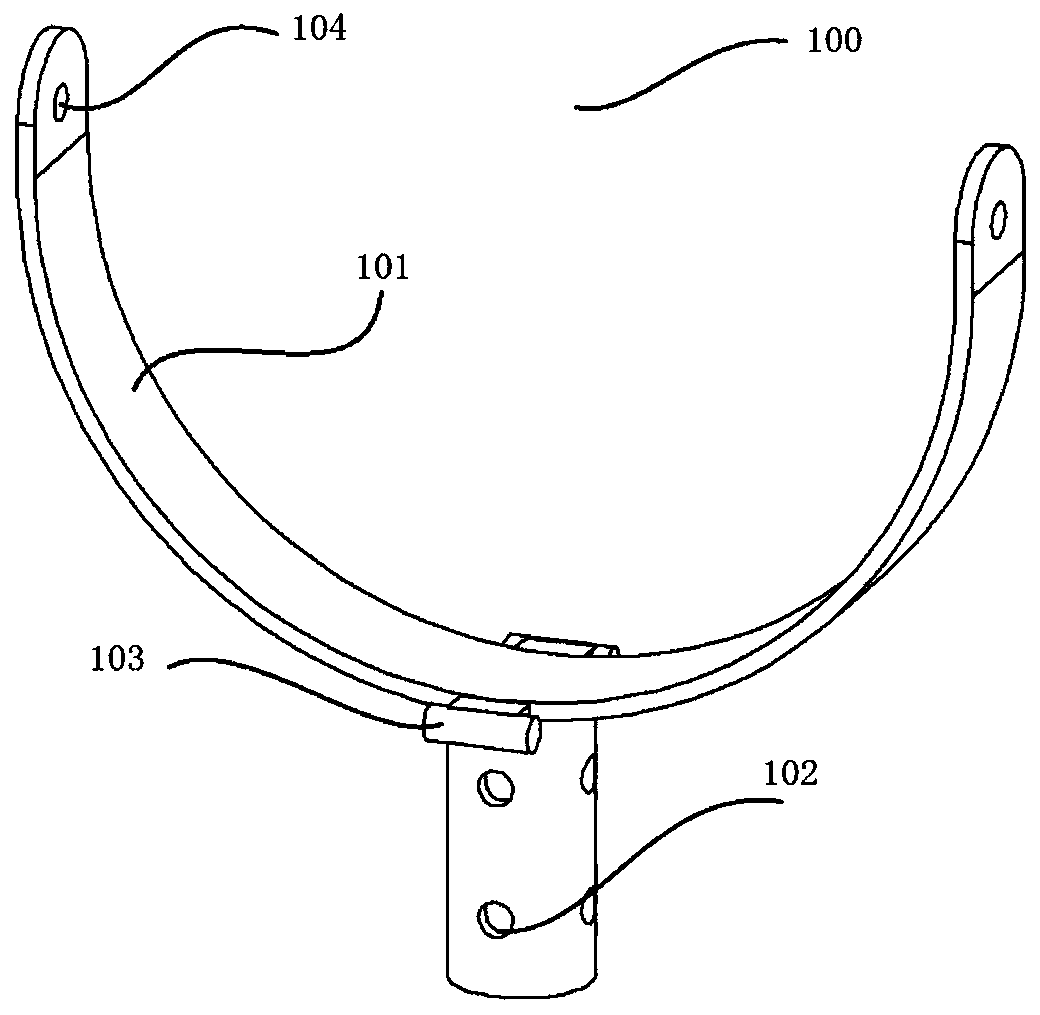

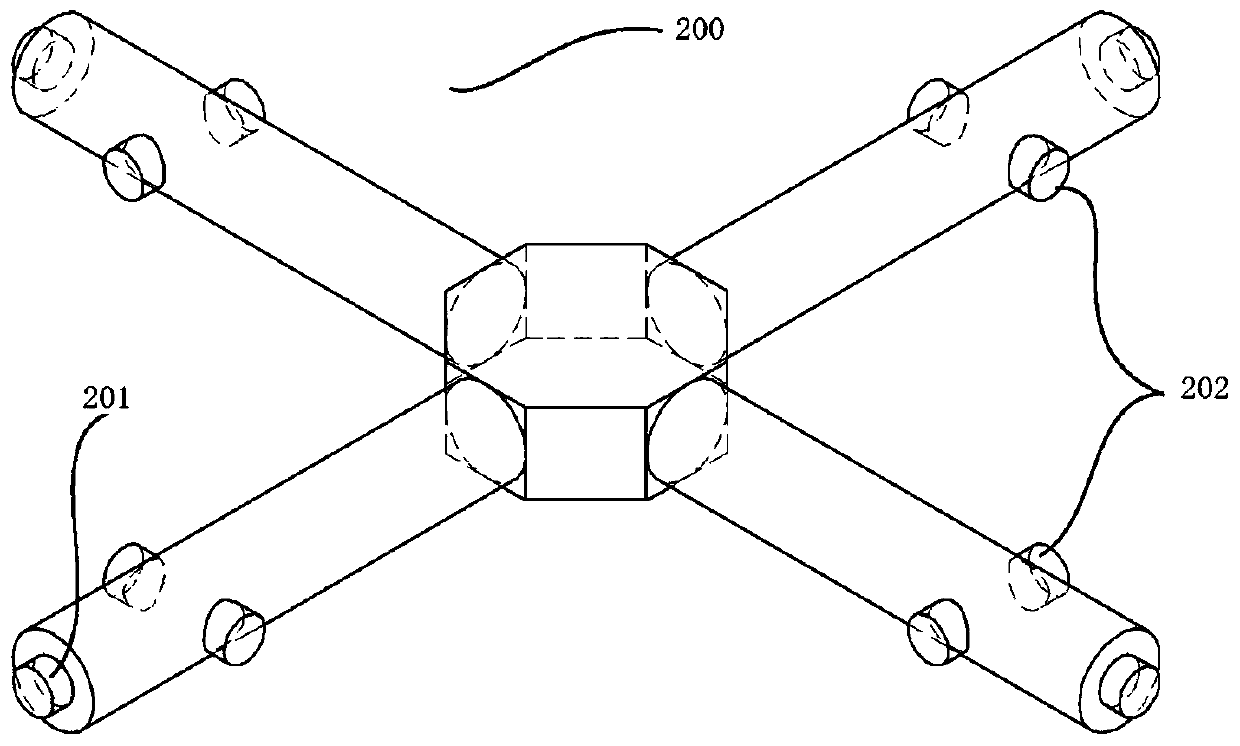

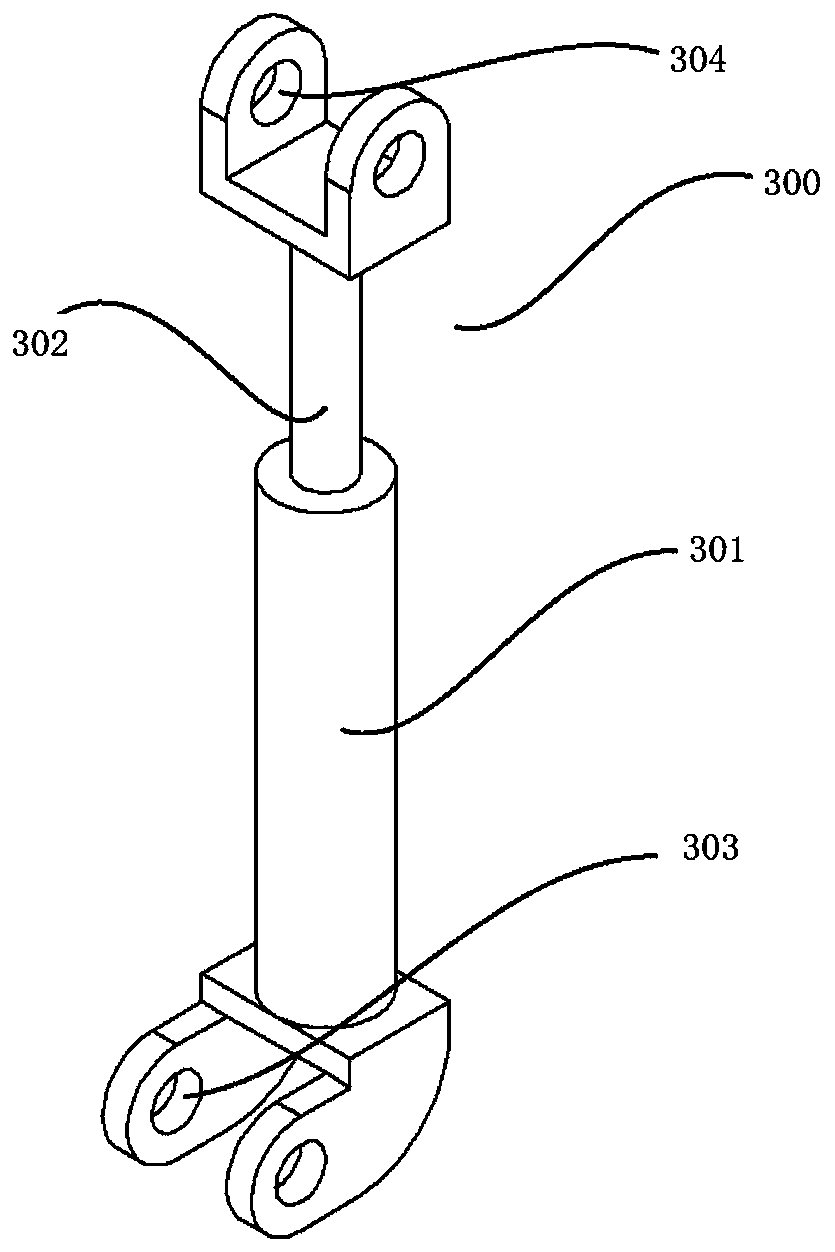

[0020] like Figure 5 As shown, an elastic damping universal joint of the present invention includes a fixed fork 100 , a cross shaft 200 , a linear damper 300 and a spring 400 . like figure 1 As shown, the fixed fork 100 includes a yoke portion 101 with an arc-shaped structure and a yoke handle portion 102 for connecting external components. The two front ends of the yoke portion 101 are respectively provided with cross shaft fixing holes 104 for connecting the cross shaft 200. The four shaft ends of the corresponding cross shaft 200 respectively have a fixed fork fixing part 201 that is compatible with the cross shaft fixing hole 104; the middle part of the fork arm part 101 is provided with damper hinges on both sides near the fork handle part 102. Part 103; the fork handle part 102 is a hollow cylindrical structure, and there are threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com