A kind of stainless steel wire section coiling and drawing machine

A technology of winding and drawing machine and stainless steel, applied in the field of PLC programmable controller, can solve the problems of scratches, diameter compression deformation, limited length of steel wire, etc., and achieve the effect of convenient movement and expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

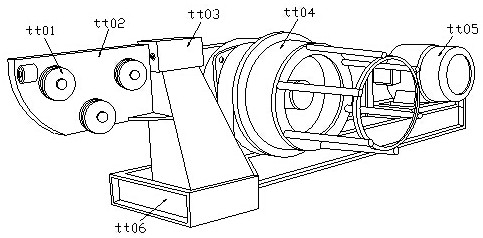

[0030] as attached figure 1 to attach Figure 5 Shown:

[0031] The invention provides a coiling and drawing machine for stainless steel wire sections, the structure of which includes an adjustment pull tube tt01, a side support plate tt02, a joint adjustment port tt03, a retracting tube tt04, a control end tt05, and a bottom support frame tt06.

[0032] The adjustment puller tt01 is installed on the outer surface of the side support plate tt02, the side support plate tt02 is welded to the surface of the joint adjustment port tt03, the joint adjustment port tt03 is connected with the bottom support frame tt06, and the retracting cylinder tt04 is set On the side of the control terminal tt05.

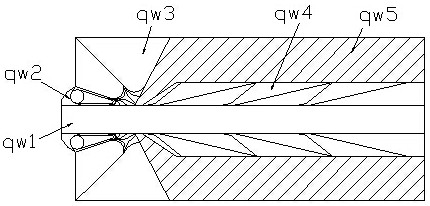

[0033] The connecting mouth tt03 includes a hollow opening qw1, a necking edge qw2, a hard corner qw3, a shovel tip qw4, and an outer pocket shell qw5. The hollow mouth qw1 is embedded in the outer shell qw5, and the necking edge qw2 and The hard angle qw3 is connected, and the shovel ...

Embodiment 2

[0040] as attached Image 6 to attach Figure 7Shown:

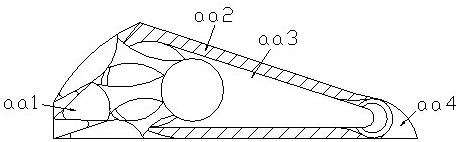

[0041] Wherein, the shovel tip qw4 includes a shovel edge dd01, a spacer dd02, and an anchor block dd03, the spacer dd02 is connected to the anchor block dd03, and the end of the spacer dd02 far away from the anchor block dd03 is connected to the shovel The corners dd01 are connected, the retaining block dd03 is a triangular structure, the spacer dd02 is provided with three, and the shovel corner dd01 allows the outer layer to have a certain hardness to smooth out objects protruding from the plane outside. The spacer dd02 makes the connecting parts more stable under stress.

[0042] Wherein, the shovel edge angle dd01 includes push angle vv1, hard shell vv2, solid force angle vv3, rubber edge vv4, and pressure-relieving ball vv5, the rubber edge vv4 is attached to the outer surface of the pressure-relieving ball vv5, and the Angle vv3 is embedded inside the hard shell vv2, the hard shell vv2 is connected with the push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com