Silencing improved control valve for oil pump

A control valve and mute technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of control valve noise, increase the pumping pressure of the oil pump, increase the load of the oil pump, etc., and achieve the effect of reducing polarization noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

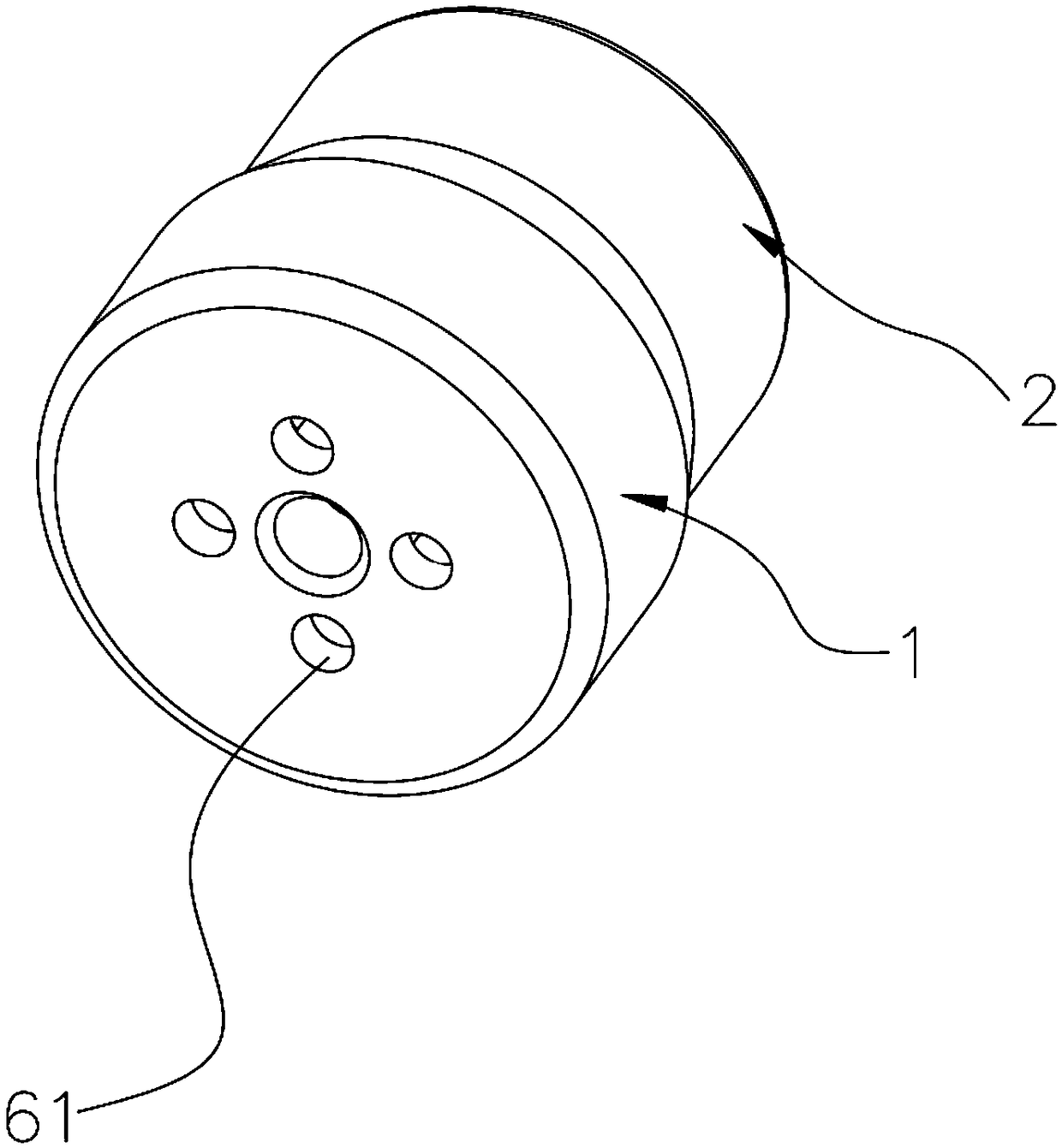

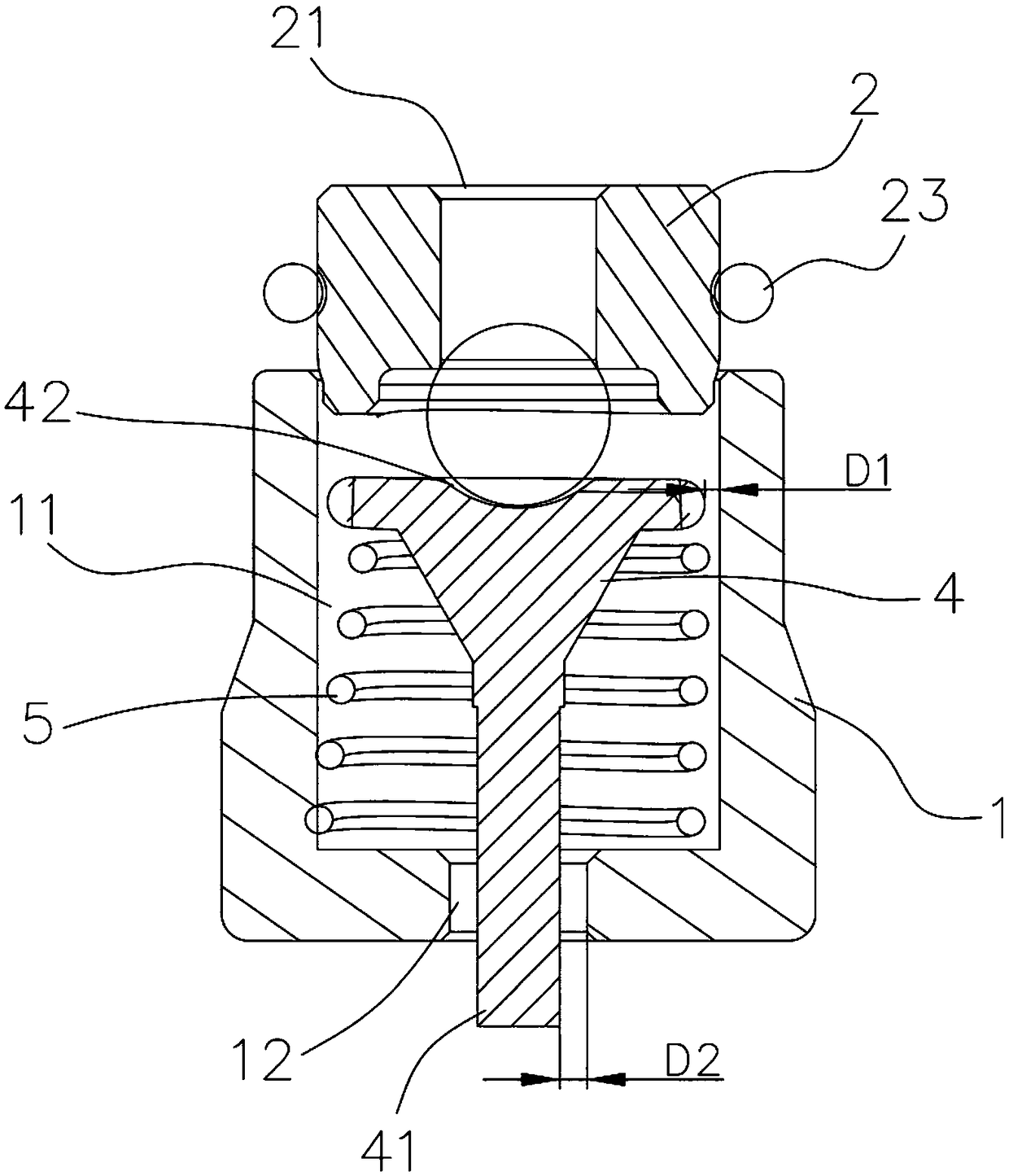

[0024] see figure 1 , figure 2 , Figure 4 , an improved silent control valve for an oil pump according to the present invention, comprising a valve seat 1, the valve seat 1 is provided with a valve cavity 11 and a mixing guide hole 12 communicating with the valve cavity 11, and the surroundings of the mixing guide hole are evenly distributed. An oil distribution hole 13 also includes a valve core 2, a sealing ball 3 and a push seat 4 for pushing the sealing ball 3, the valve cavity 11 is provided with an elastic mechanism 5, and the valve core 2 is provided with a through oil passage 21, so The inner end of the through oil passage 21 is provided with an arc flare 22 matched with the sealing ball 3, and the push seat 4 is provided with a guide column 41, and the guide column 41 extends to the outside of the mixing guide hole 12, and the elastic The mechanism 5 is socketed on the guide column 41 and drives the push seat 4 to move along the valve cavity 11. The push seat 4 pu...

Embodiment 2

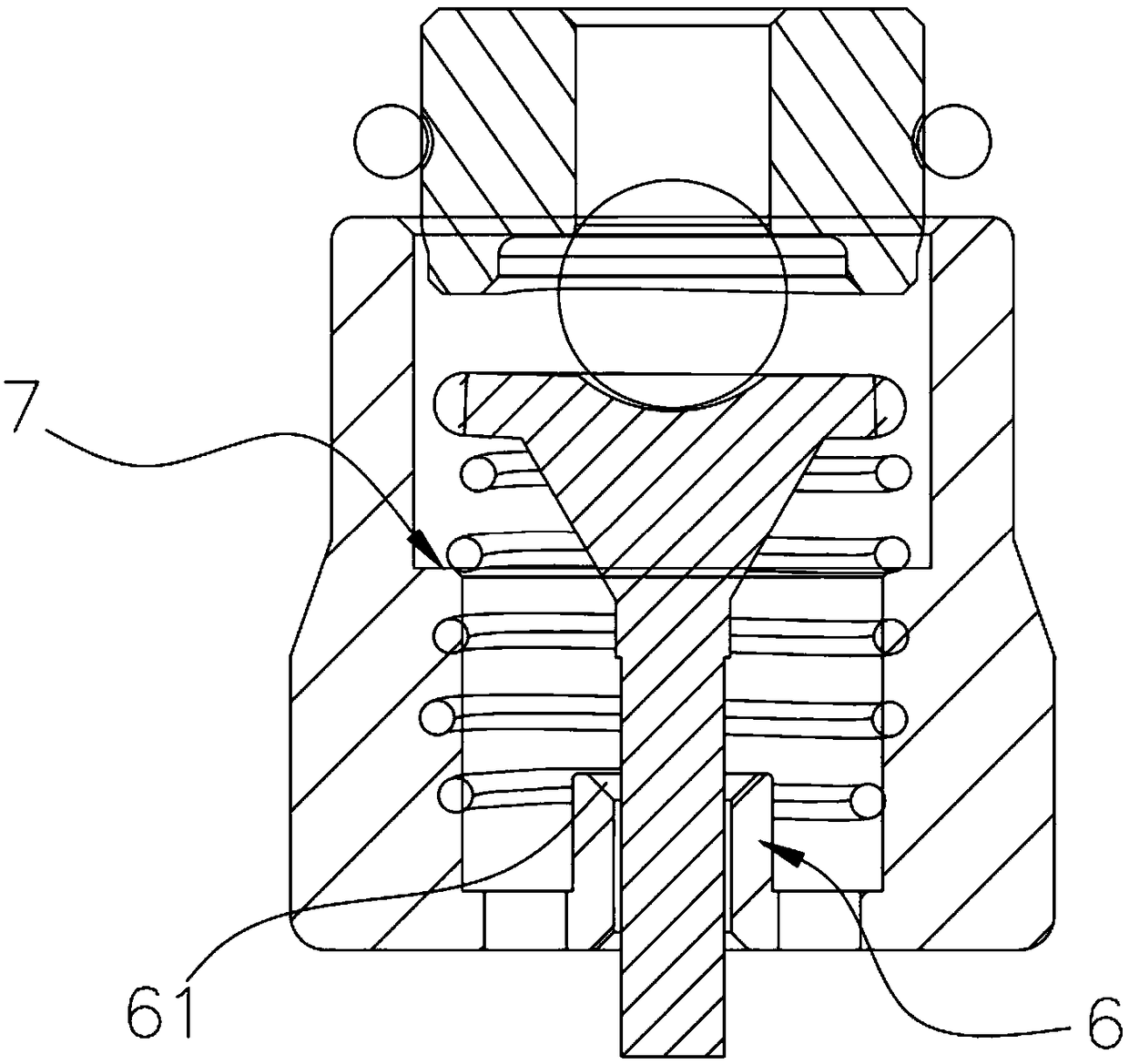

[0033] see image 3 , the present embodiment is further improved and optimized on the basis of Embodiment 1, because 50% of the noise of the whole control valve is generated from the elastic mechanism (such as a spring) under the resonance of the repeated movement of the sealing ball 3, so that the push seat 4 and the valve The inner wall of the cavity 11 forms a bumping noise. In view of this, in order to make the push seat can be guided by the guide post 41, the mixing guide hole is provided with a guide protruding ring extending into the valve cavity, and the guide post passes through the guide post 41. Convex ring6.

[0034] As for the height of the guide protrusion ring 6, in the present technical solution, the extension height of the guide protrusion ring 6 is equal to or greater than 1mm, and those skilled in the art can set a higher guide protrusion according to the larger stroke of the push seat 4. Ring, the inner end of the guide protruding ring 6 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com