Folding screen rotary shaft and folding screen electric equipment

A shaft and shaft core technology, which is applied in the field of folding screen shafts and folding screen electronic equipment, can solve the problems of large product thickness, flexible screen pulling force, and affecting the stability of flexible screens, so as to reduce product thickness, avoid pulling force, and ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

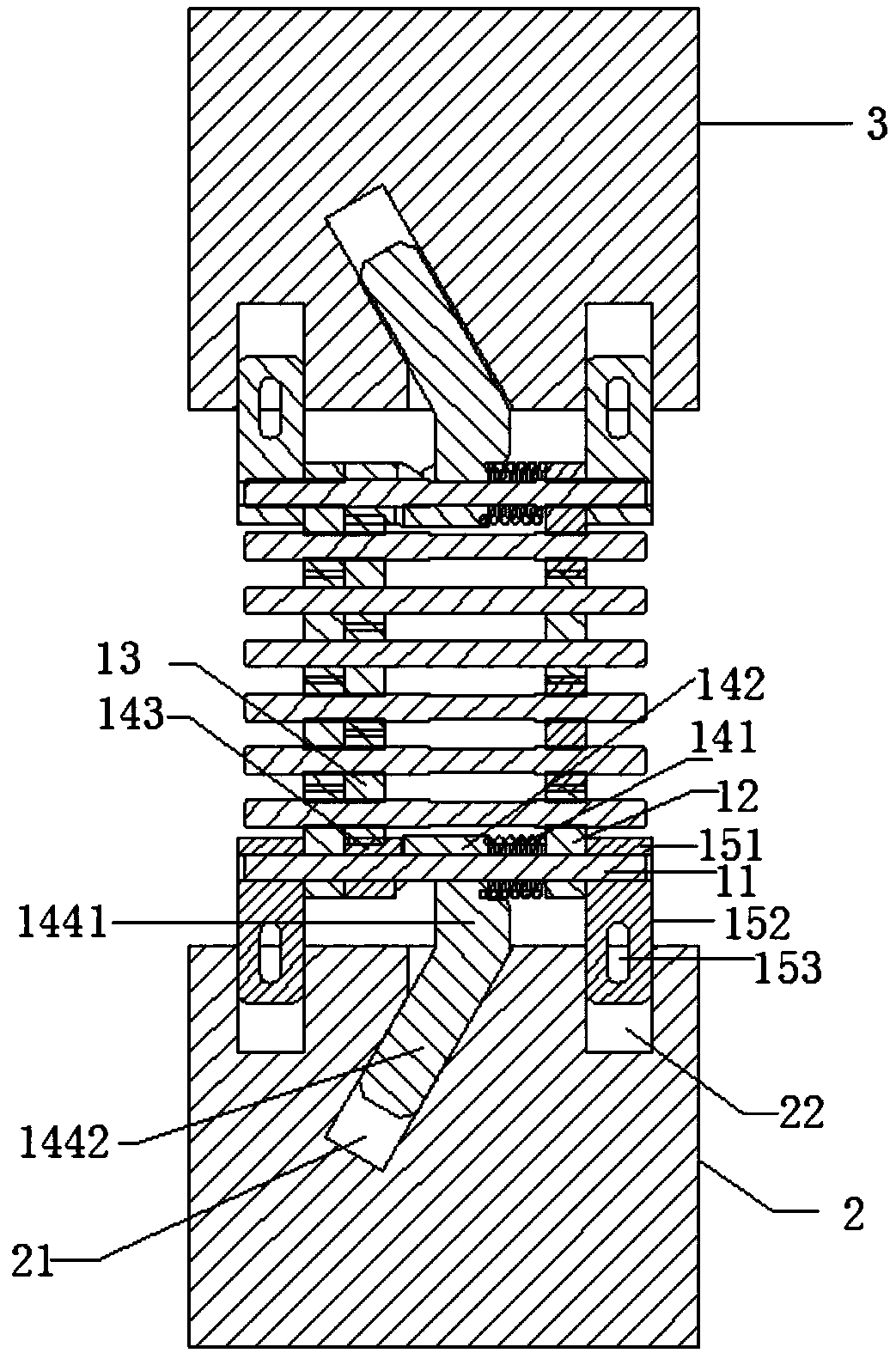

[0022] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention. The components in the structures in the drawings of the embodiments are not scaled according to the normal scale, so they do not represent the actual relative sizes of the structures in the embodiments. The above or upper side of the structure or surface includes the case where there are other layers in the middle.

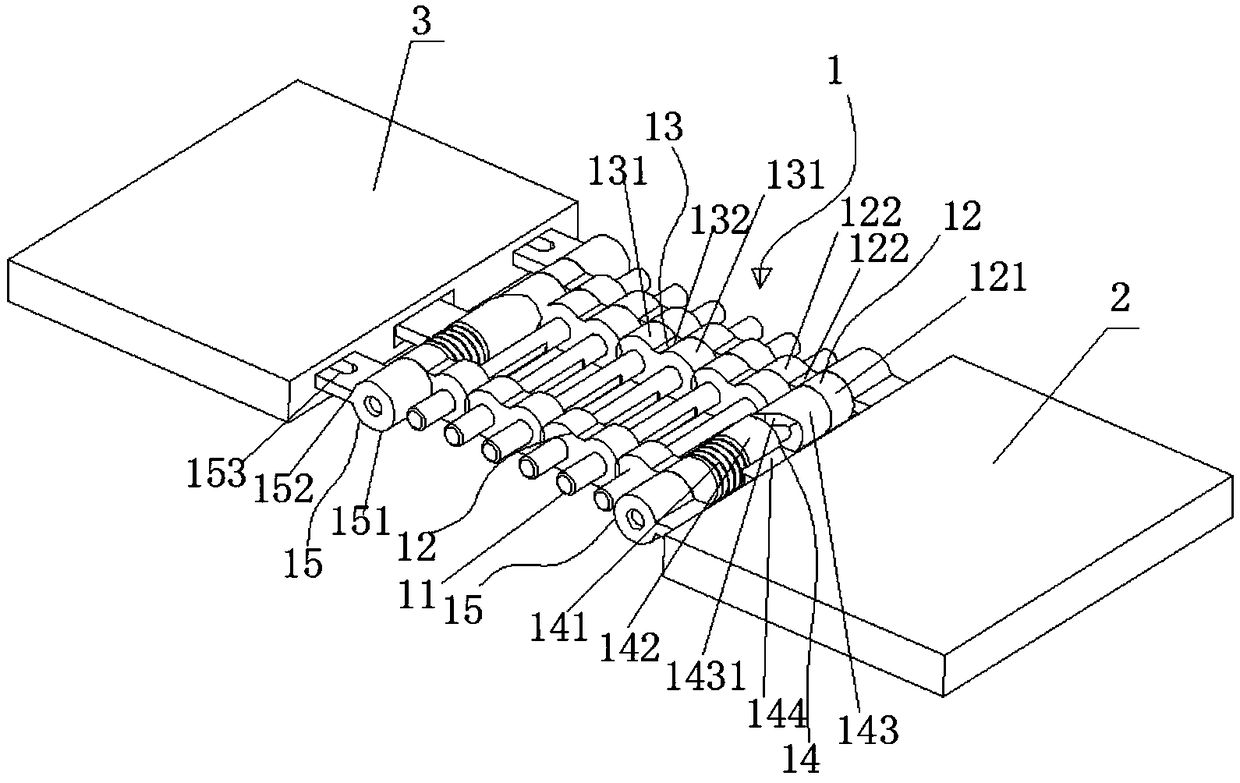

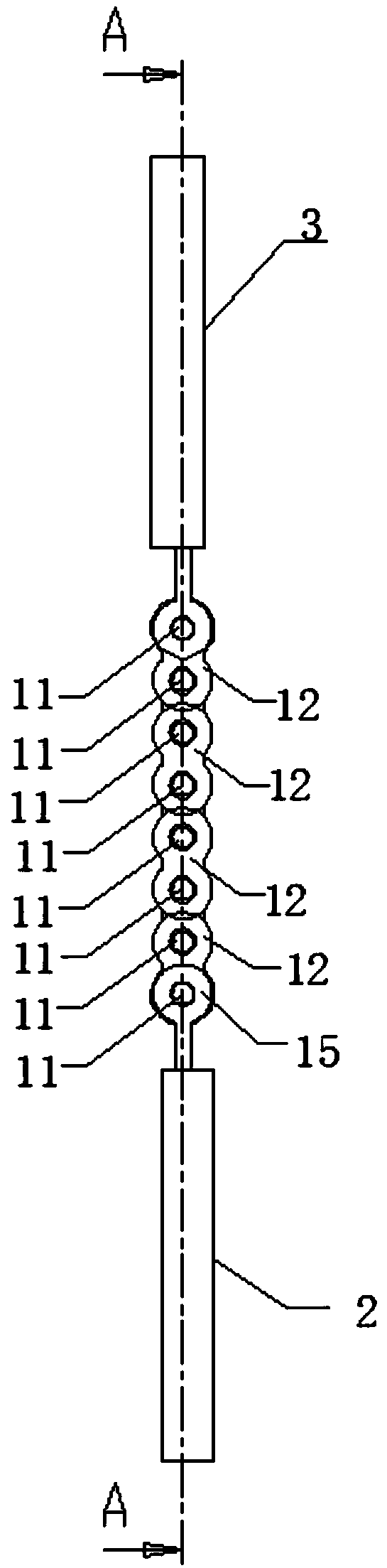

[0023] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, a folding screen rotating shaft 1 includes several link gear shafts, and each link gear shaft includes two shaft cores 11 arranged in parallel at intervals and coated and sleeved on the two shaft cores at intervals in the axial direction. Two link gears A12 on the upper, each link gear A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com