Current detection device of motor driver, and motor driver

A motor driver, output current detection technology, applied in the direction of AC motor control, electrical components, analog-to-digital converters, etc., can solve the problems of inaccurate output torque of the motor driver, common cause failure, and low torque control accuracy of the motor driver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

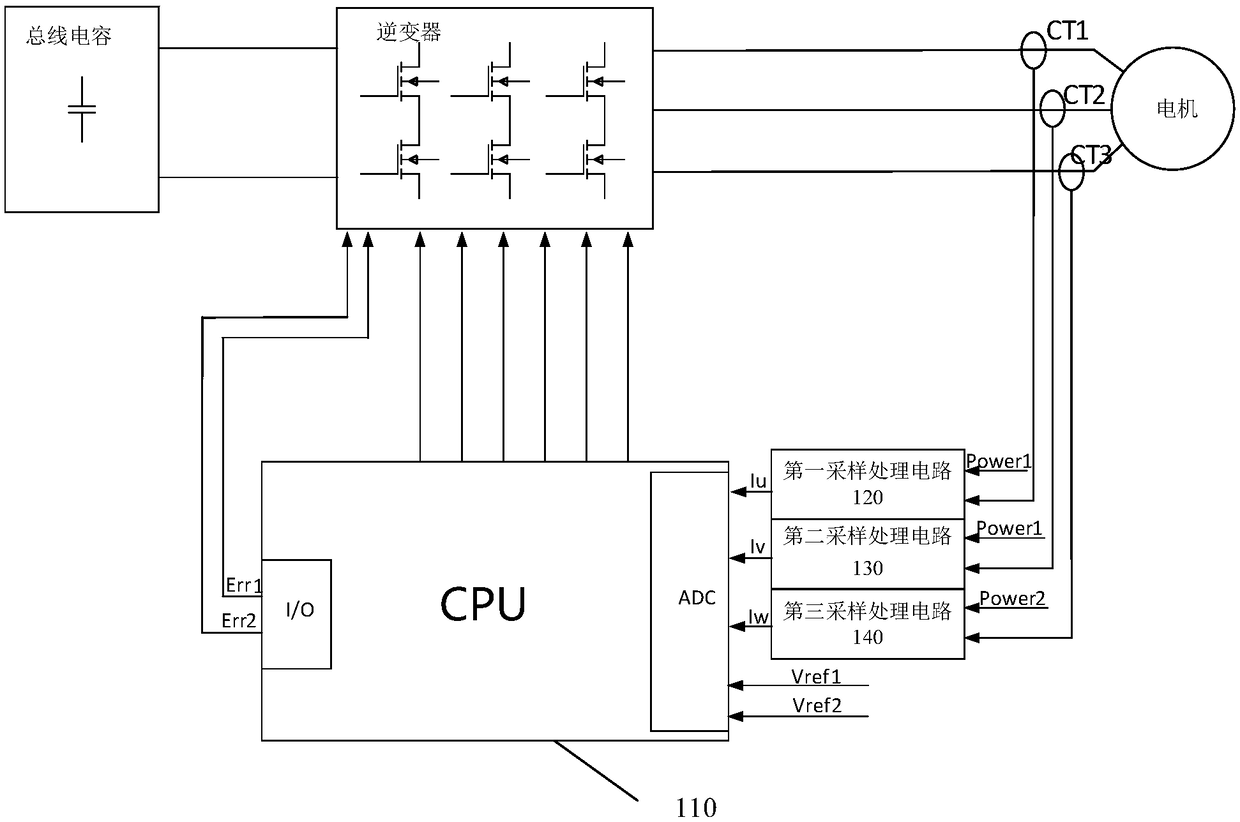

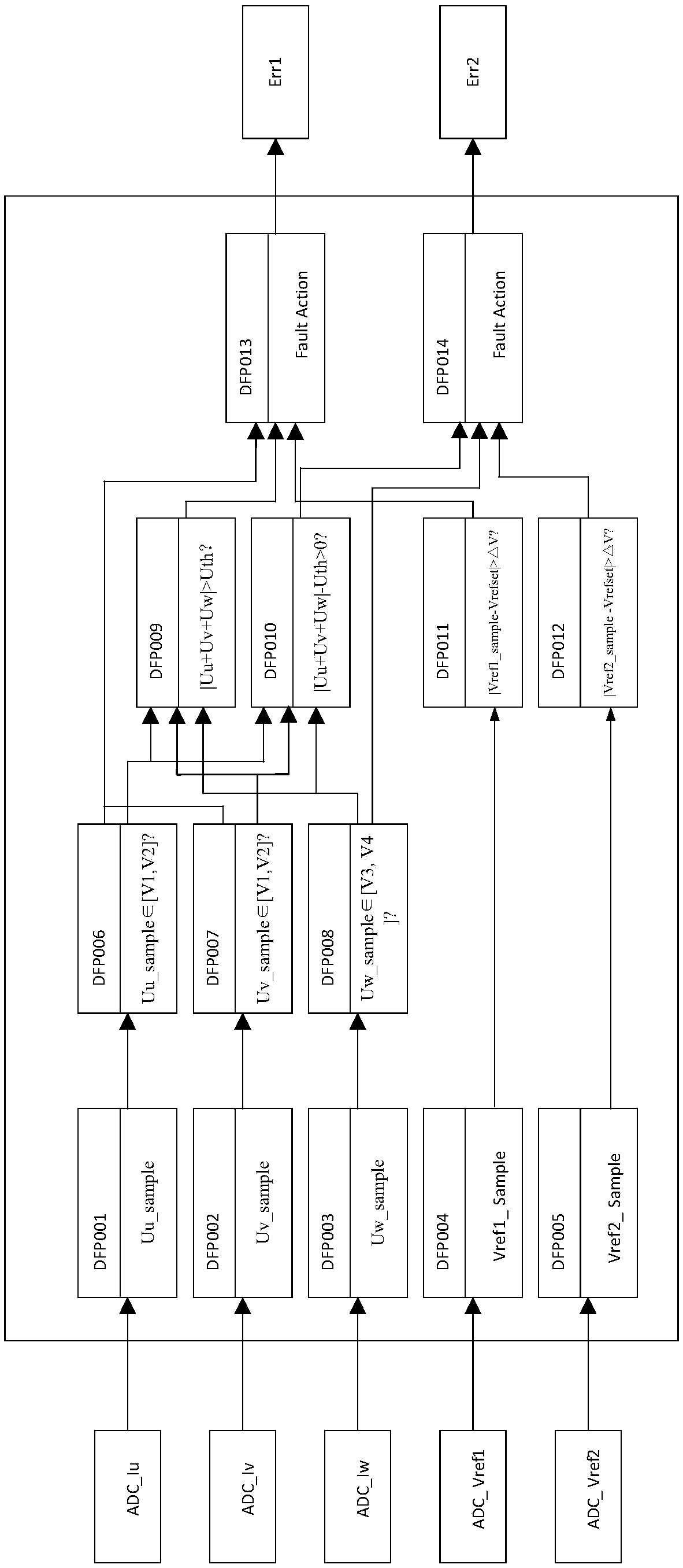

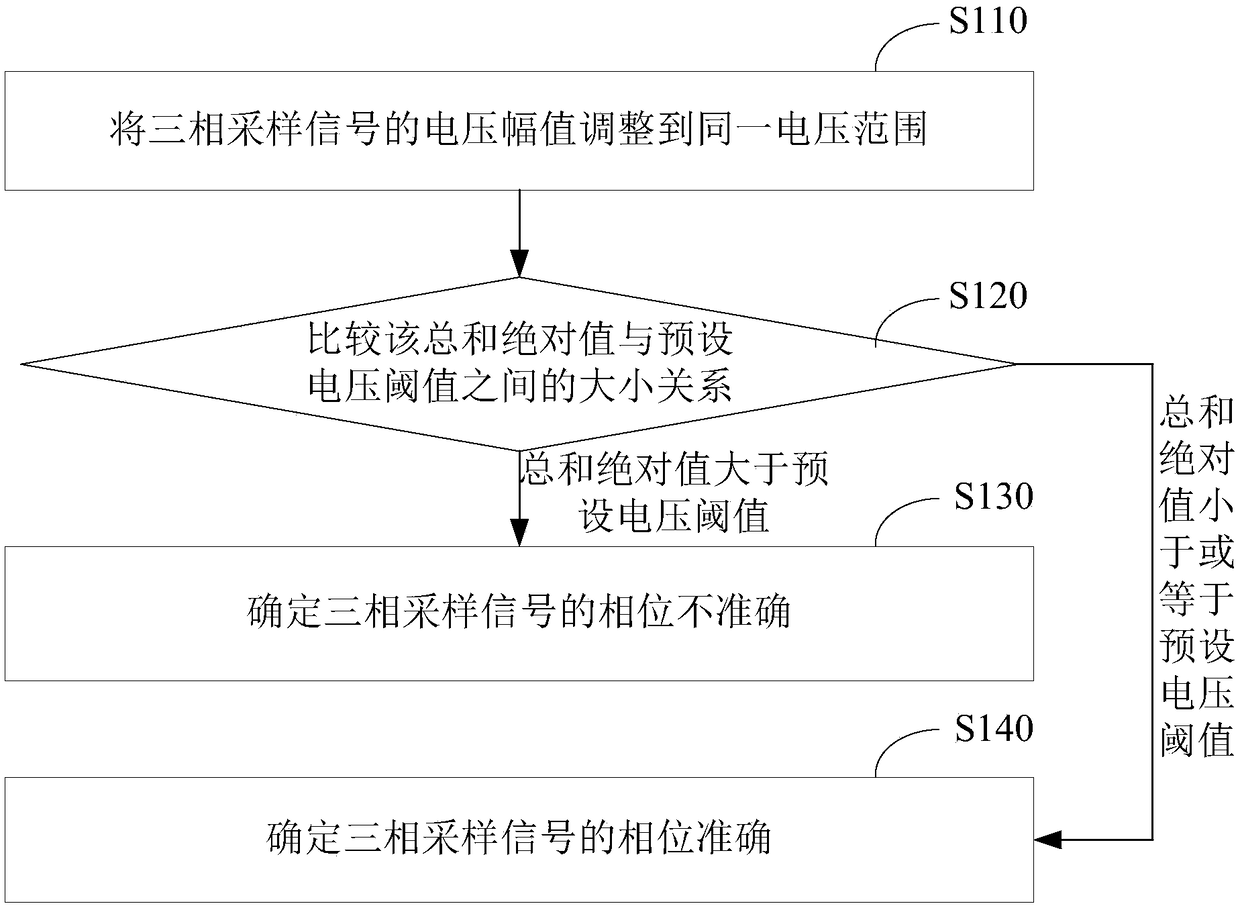

[0048]The current sampling method of the output current of the motor driver does not deal with the common cause failure, which makes it impossible to verify the rationality of the sampled voltage signal. The present application provides an output current detection device of a motor driver, which uses a three-phase current sampling sensor to sample the output current of the motor driver. In the output current sampling loop, the power supply of the sampling module and the conditioning range of the sampling signal are dealt with accordingly, so as to reduce the possible common cause failure factors in the sampling loop as much as possible. Then, the rationality of the obtained sampling signal is checked to ensure the accuracy of the output current sampling, and finally avoid the risk of uncontrollable output torque of the motor driver.

[0049] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com