Intelligent rotating packing tower

A packed tower and revolving technology, which is applied in the field of intelligent revolving and rotating packed towers, can solve the problems of air intake resistance, dust removal and desulfurization effects, increased capital investment for itself and the tower body, and easy loss of fluidized balls Problems such as drop-off boards can be avoided to achieve the effects of avoiding airflow energy loss, simple structure, and reduced land use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

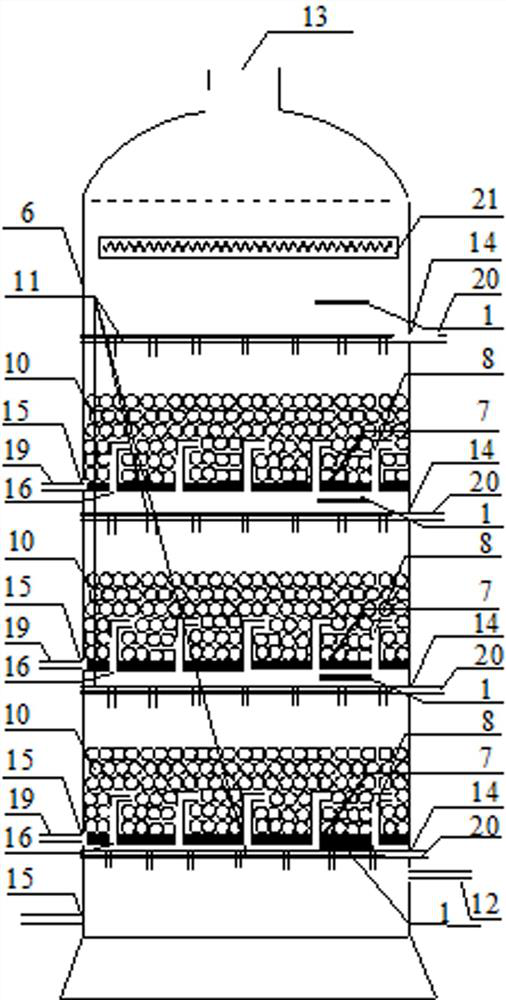

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

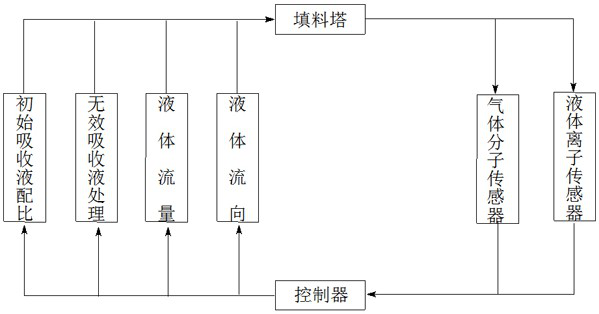

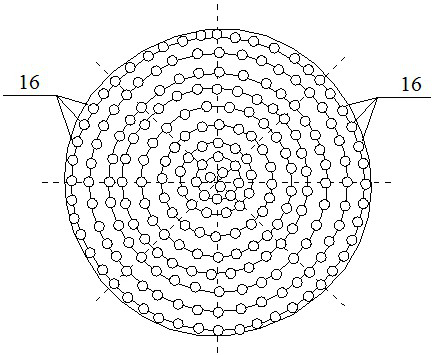

[0035] Such as figure 1 , 2 As shown, the present invention includes a control system, a cylinder body 6, three groups of absorption liquid spray assemblies, a mist eliminator 21 and a pre-absorption structure. The bottom of the cylinder body 6 is provided with an air inlet 12 and an absorption liquid outlet hole 15, The air inlet 12 is arranged along the tangential direction of the inner wall of the cylinder, and the top of the cylinder 6 is provided with an air outlet 13 . The three groups of absorption liquid spray assemblies are installed horizontally in the cylinder body 6 respectively, and the demister 21 is placed in the cylinder body 6 above the three groups of absorption liquid spray assemblies. Said pre-absorption structure is installed in the cylinder body 6 and located between the absorption liquid spray assembly and the air inlet 12 . The pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com