Auxiliary grinding, polishing and processing system for plane stone plates

An auxiliary system, slate technology, applied in the direction of grinding/polishing equipment, grinding/polishing safety devices, metal processing equipment, etc., can solve the problems of time and energy consumption, no provision, etc., to achieve easy installation and erection, stable working process , the effect of compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] The technical solutions of the present invention are further described below, but the claimed scope is not limited to the description.

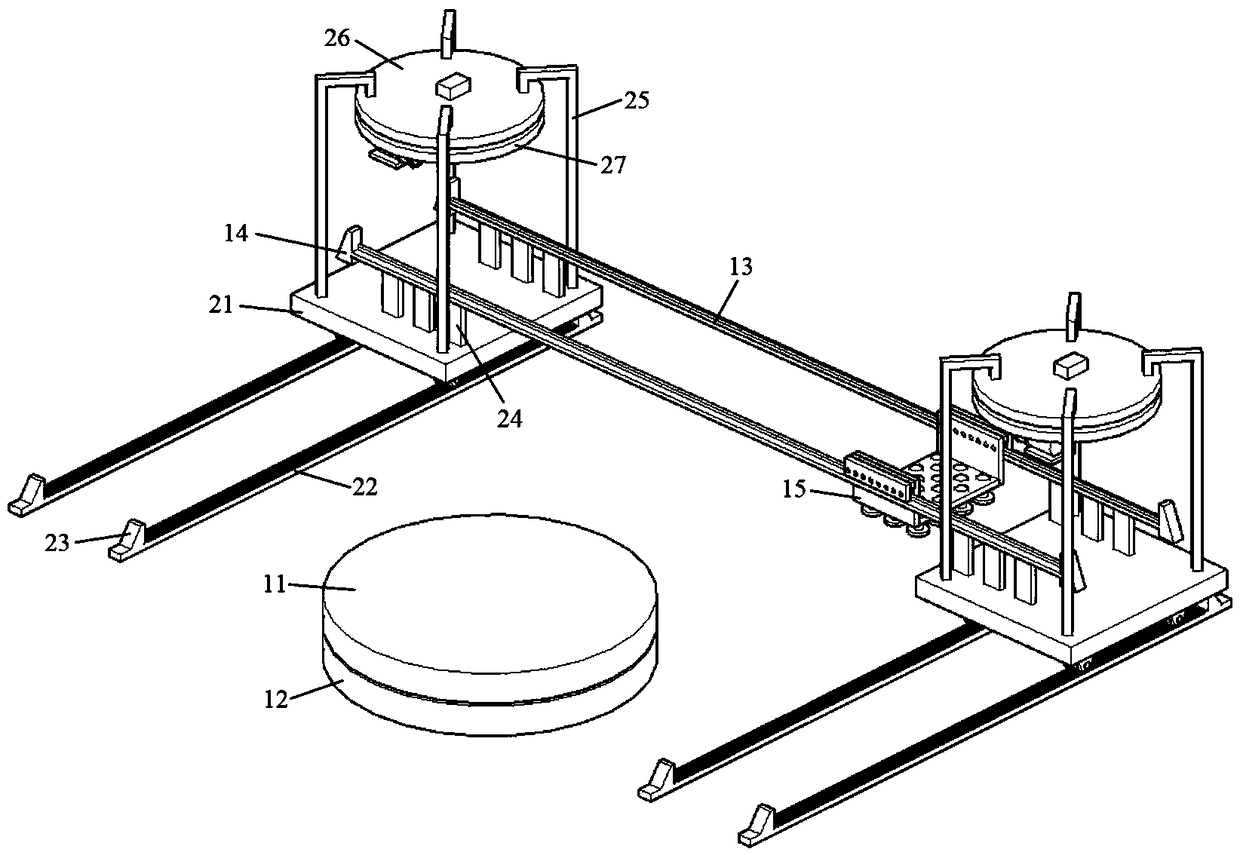

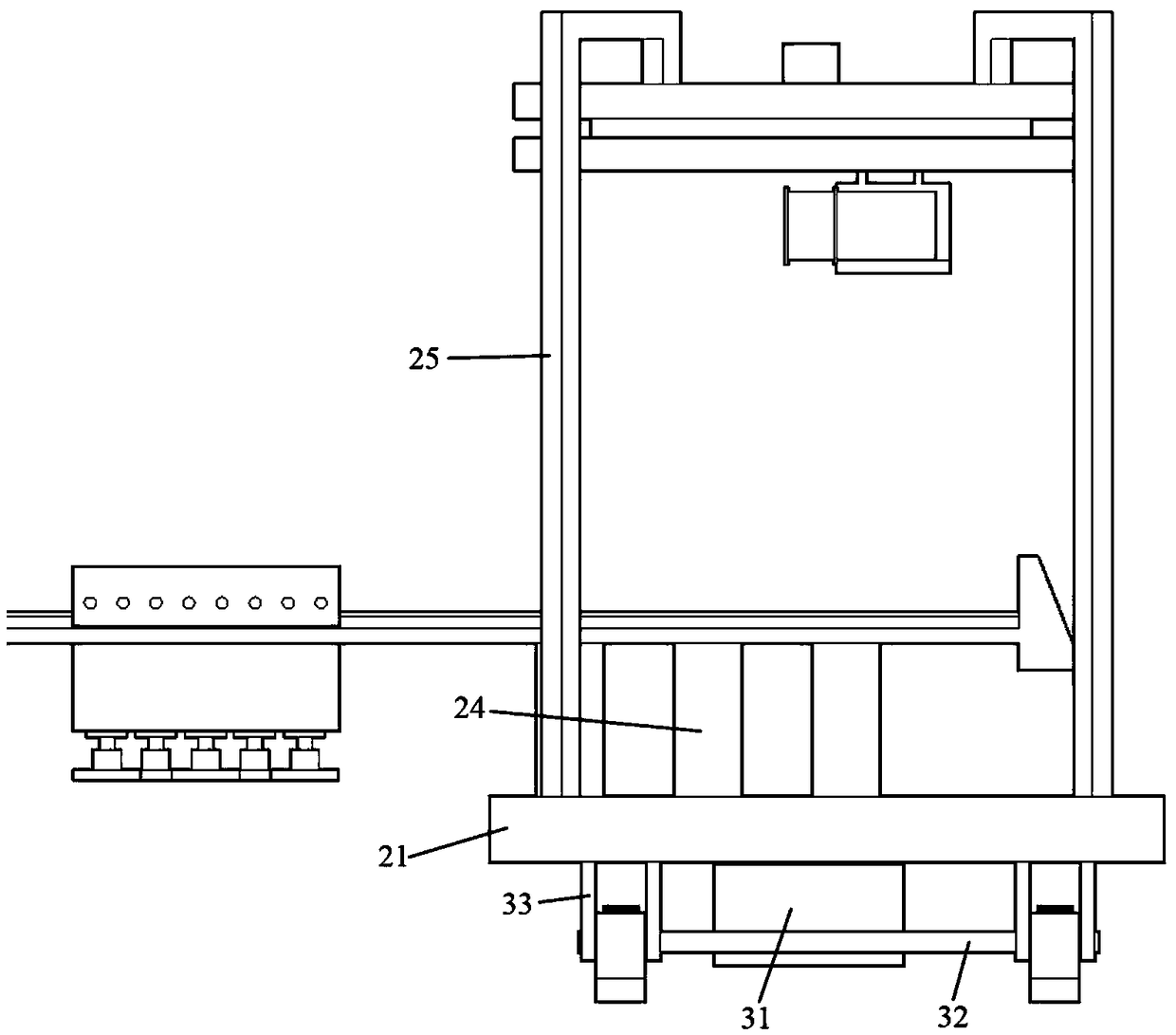

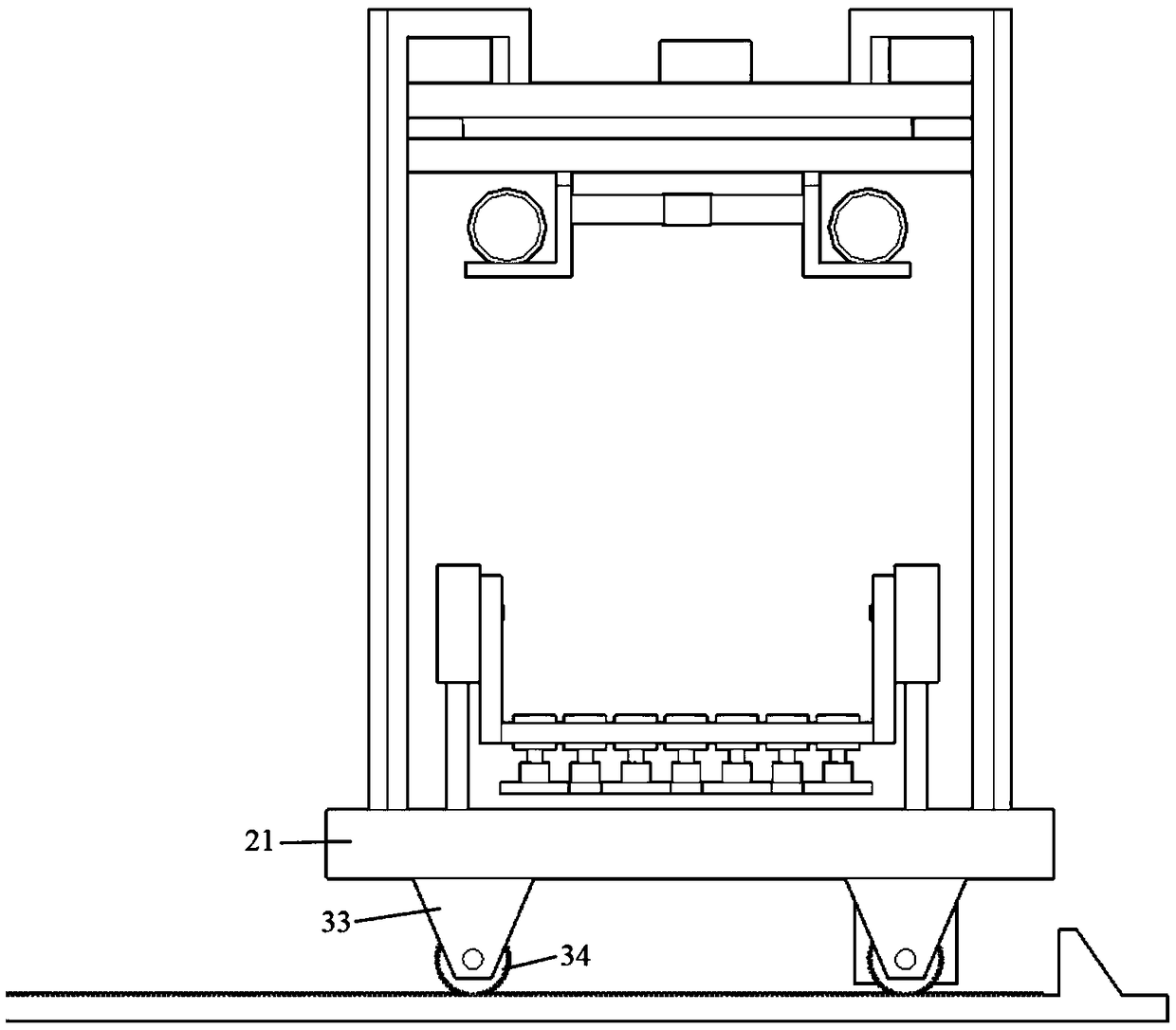

[0020] like Figure 1 to Figure 3 The shown auxiliary system for grinding and polishing a flat slate includes an upper bracket 11, a guide rail 13, and a carriage 15; the carriage 15 is mounted on the guide rail 13 and can move along the guide rail 13, and the bottom of the carriage 15 is provided with a A plurality of grinding discs, both ends of the guide rail 13 are fixed on the fixed block 21, the middle of the fixed block 21 is vertically fixed with a guide rail fixed block 24, the guide rail 13 is fixed on the upper end of the guide rail fixed block 24, and the four corners of the fixed block 21 are vertically fixed with vertical rods 25, The top of the vertical rod 25 is bent downward and points to the middle of the fixed block 21. The upper end of the vertical rod 25 is fixed on the upper surface of the upper wheel plate 26. Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap