A kind of bubbling type mixed fuel boiler and method thereof

A mixed fuel and boiler technology, applied in the field of boilers, can solve the problems of combustion explosion, uncontrollable combustion process, difficult control of the mixed environment of ethanol vapor and combustion air, etc., and achieve the effect of improved combustion efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the drawings.

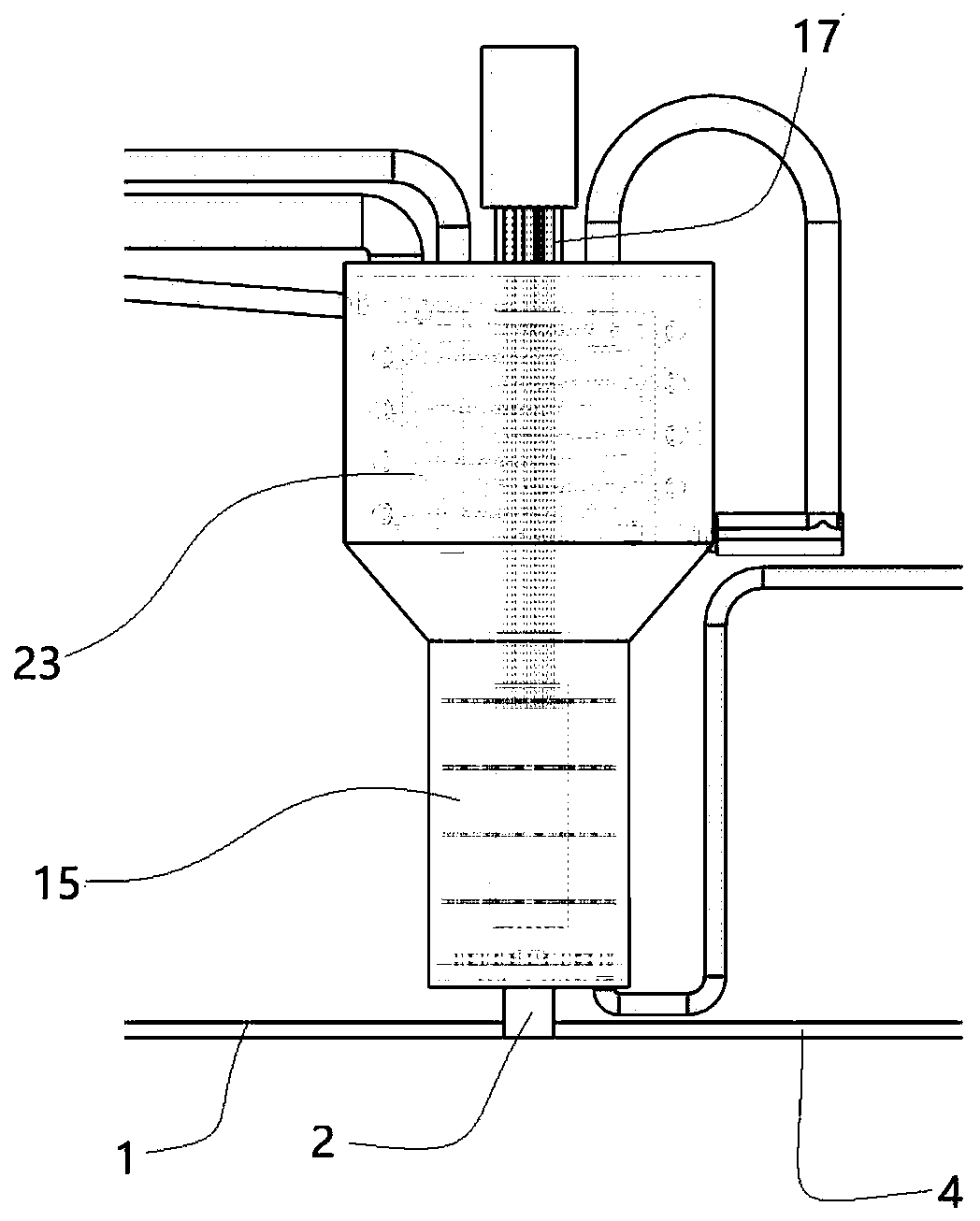

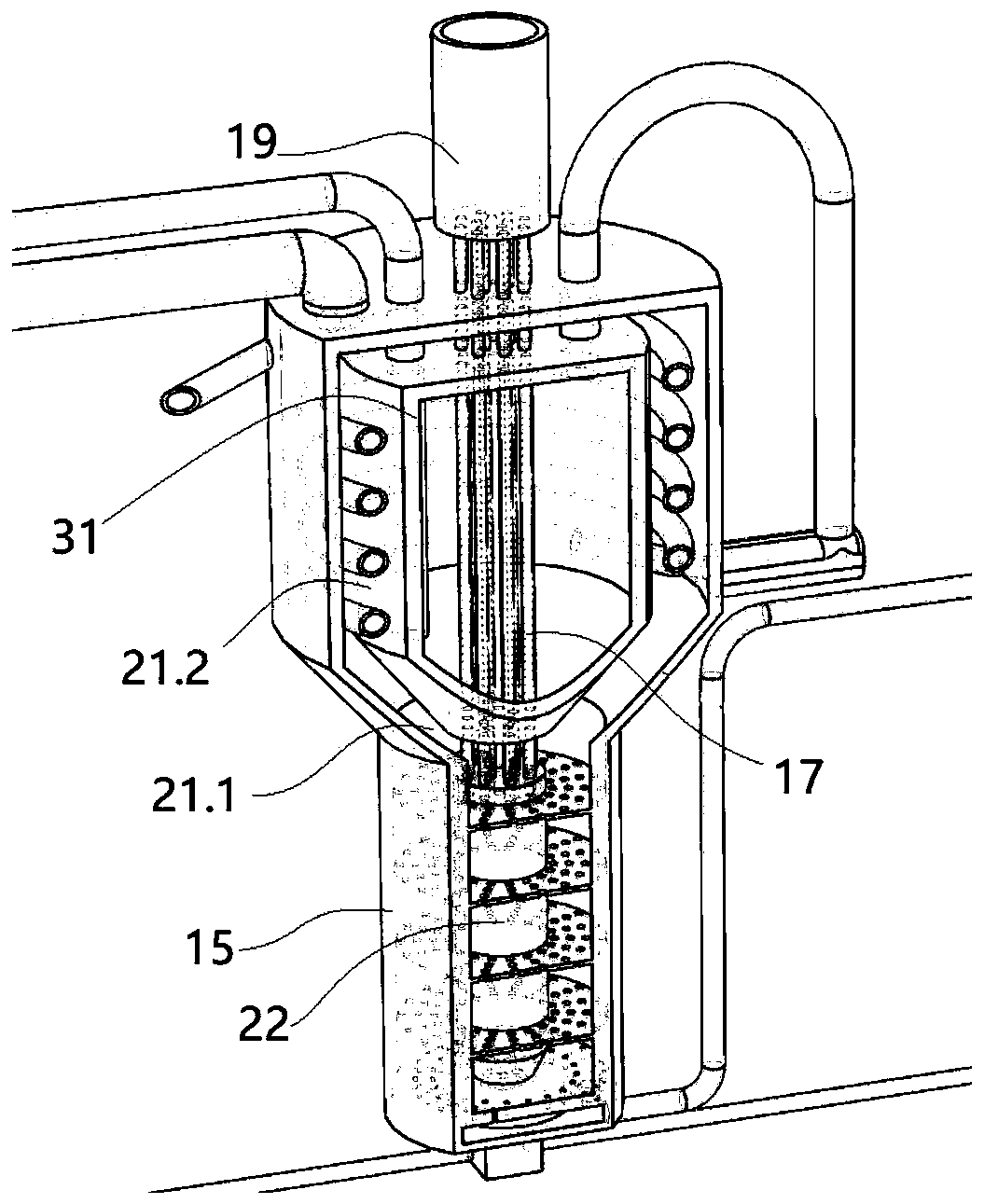

[0024] As attached Figure 1 to 5 A bubbling mixed fuel boiler shown, ethanol steam generating furnace body 15 and combustion heating furnace body 23;

[0025] The ethanol steam generating furnace body 15 is an upright cylindrical shell structure; the combustion heating furnace body 23 is a "gyroscopic" shell structure with the tip down; the upper end of the ethanol steam generating furnace body 15 is connected to the combustion heating The lower end of the furnace body 23 is integrated and connected.

[0026] The inner cavity of the ethanol steam generating furnace body 15 is provided with a natural gas heating furnace core 22 concentrically. The natural gas heating furnace core 22 is a heat-conducting metal cylindrical shell structure. The inner concentricity of the natural gas heating furnace core 22 A cylindrical combustion chamber 7 is provided. A circular cylindrical ethanol vapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com