A three-proof air powder regulator

A regulator, air-powder technology, applied in valve details, functional valve types, devices to prevent accidental or unauthorized action, etc., can solve the problem of affecting the accuracy of pulverized coal conveying flow, and the inability of the left and right core plates to close tightly. , pipe burnout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

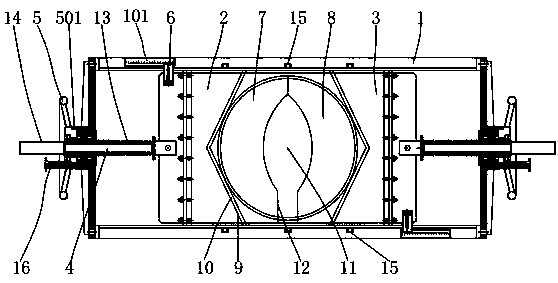

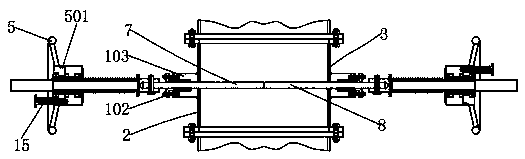

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0017] see figure 1 , the present invention provides a three-proof air powder regulator, including a valve body 1 and a left housing plate 2 and a right housing plate 3 respectively arranged on both sides of the valve body 1, a left housing plate 2 and a right housing The plates 3 are connected with a screw rod 4, one end of the screw rod 4 runs through the valve body 1 and is exposed outside the valve body 1, the end of the screw rod 4 is fixed with a hand wheel 5, and the hand wheel 5 is provided with a fine-tuning dial 501; The sides of the left housing plate 2 and the right housing plate 3 are respectively provided with an opening indicator 6; the valve body 1 is provided with a scale plate 101 corresponding to the opening indicator; the left housing plate 2. The right shell plate 3 is respectively fixed with left and right core plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com