A Life Prediction Method for Fatigue Short Crack Growth Under Multiaxial Variable Amplitude Loading

A technology of crack growth life and crack growth, applied in the field of fatigue short crack growth life prediction under multi-axial variable amplitude loading, which can solve the lack of stress intensity factor, the difficulty of multi-axial fatigue short-crack test data, and the multi-axial fatigue short-crack growth model. Slow research progress and other problems, to achieve the effect of easy engineering application and clear physical meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described with reference to the accompanying drawings.

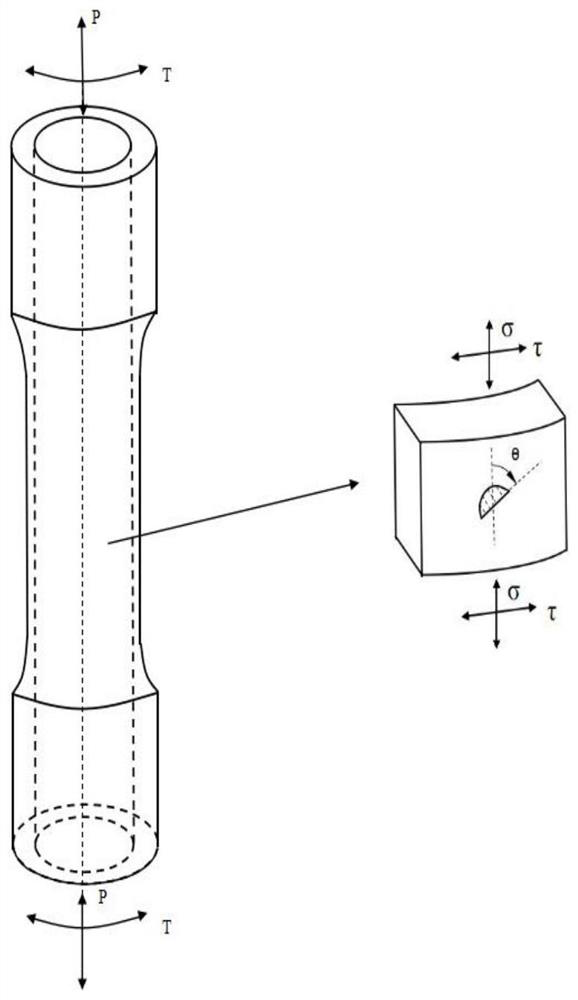

[0032] The present invention further illustrates the present invention through a fatigue test, the test is divided into two parts, one part is a short crack test under uniaxial constant amplitude loading, the stress ratio is -1, and the short crack propagation data is observed. In the range of high cycle fatigue life, there is mainly a single dominant crack, which is convenient to measure and calculate the crack growth curve. The other part is the multi-axial variable-amplitude loading test, which calculates the equivalent stress intensity factor range under the multi-axial variable-amplitude loading condition.

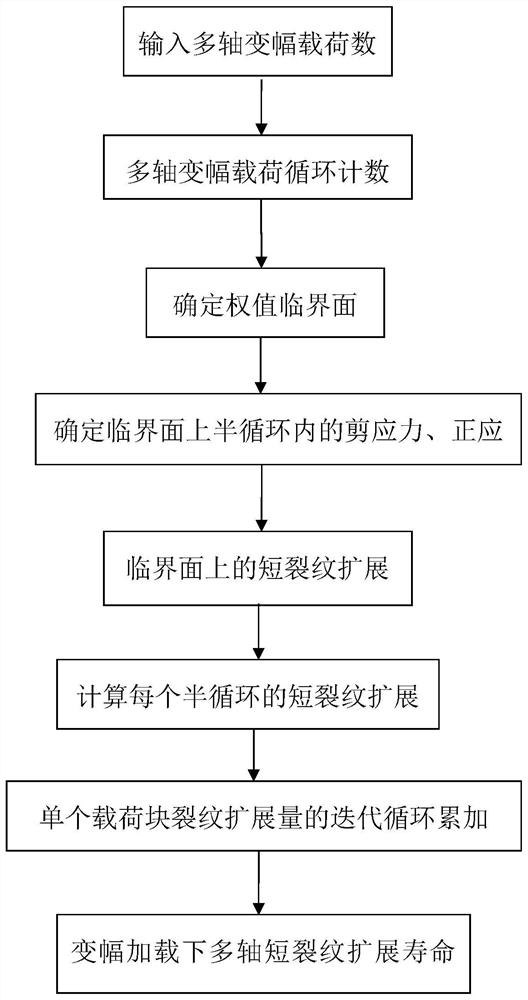

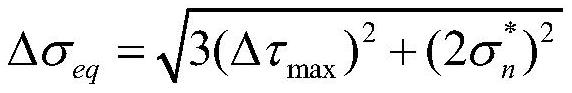

[0033] A life prediction method for fatigue short crack growth under multiaxial variable amplitude loading, the specific calculation method is as follows:

[0034] Step 1): Processing of multi-axis luffing loads and multi-axis cycle counting; in the case of multi-axis luffin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com