Serial production line buffer zone capacity allocation method based on availability evaluation

A capacity configuration and buffer technology, applied in data processing applications, instruments, calculations, etc., can solve problems such as production efficiency decline, power waste, and unfavorable early-stage development of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

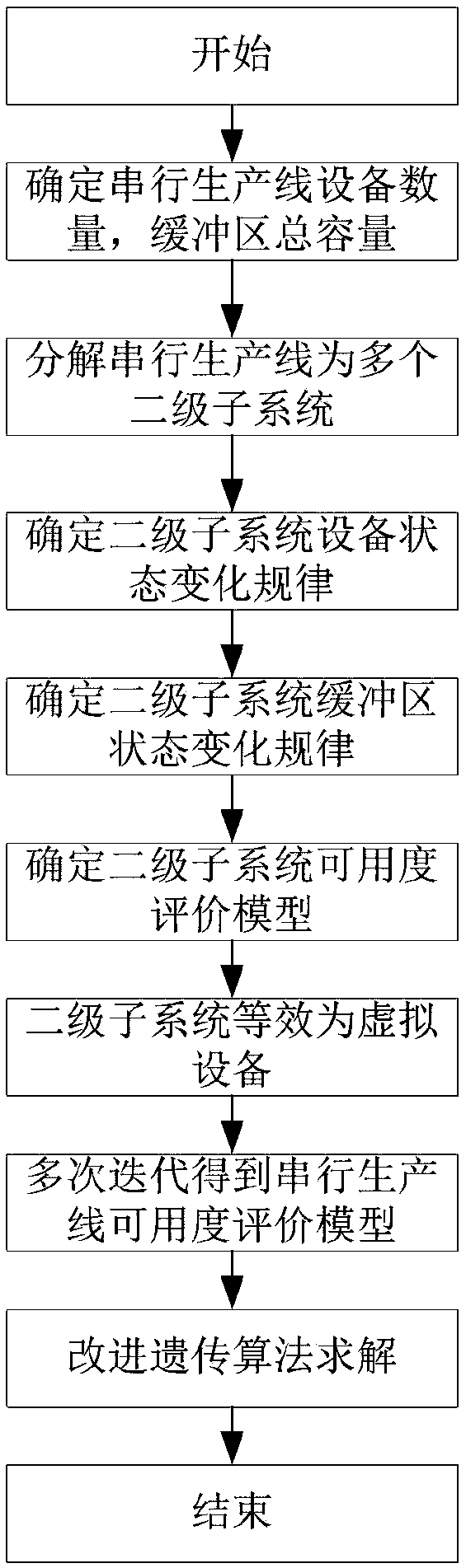

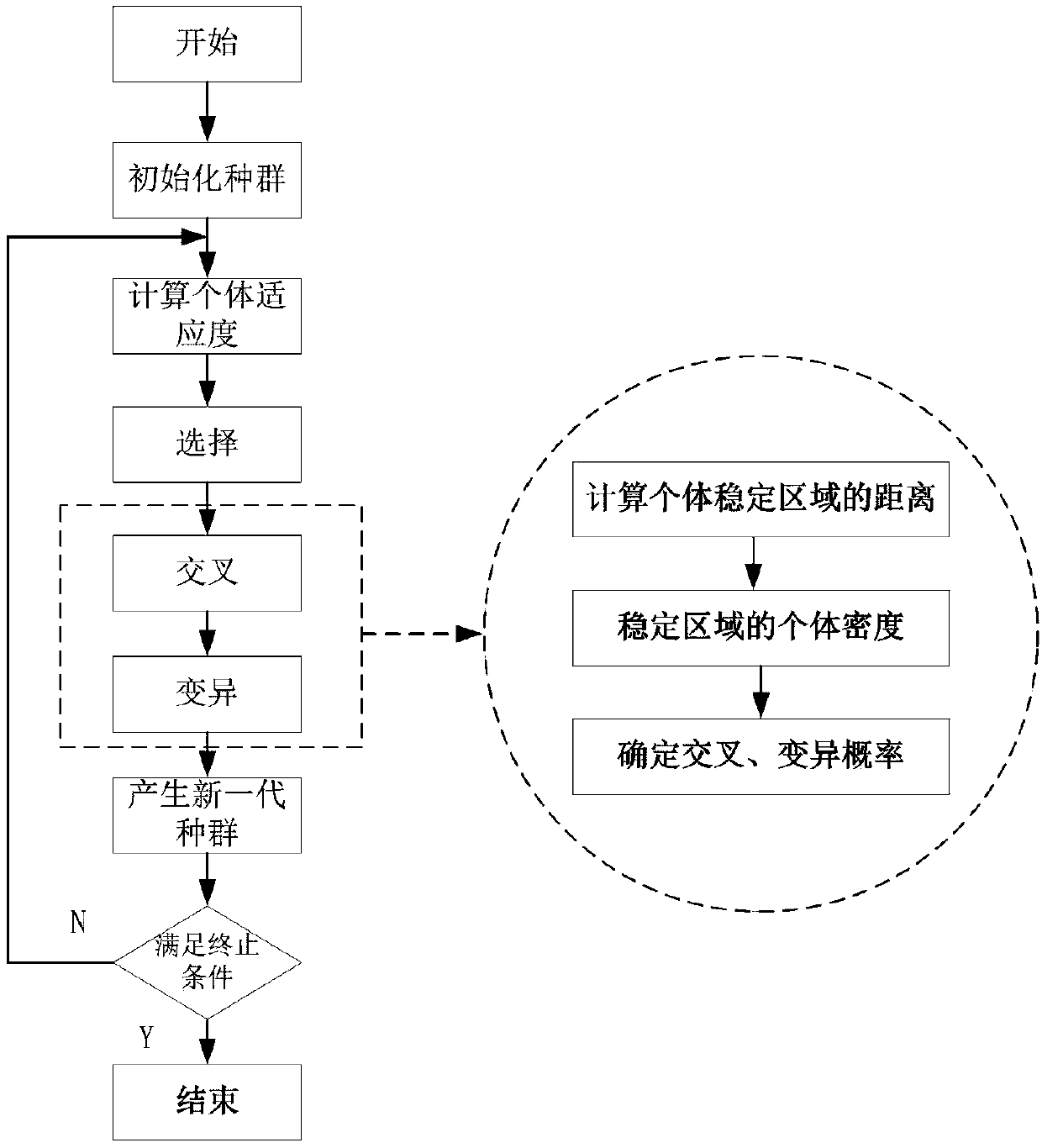

[0087] This method decomposes the serial production line into multiple secondary subsystems, solves the availability evaluation expression of the secondary subsystem, and then iteratively solves the availability evaluation model of the serial production line, and combines the improved genetic algorithm to solve the serial production line. Run the production line buffer capacity configuration scheme.

[0088] Such as Figure 1-Figure 3 As shown, the method specifically includes the following steps:

[0089] 1) Determine the number of serial production line equipment and the total buffer capacity;

[0090] 2) Decompose the serial production line into multiple secondary subsystems;

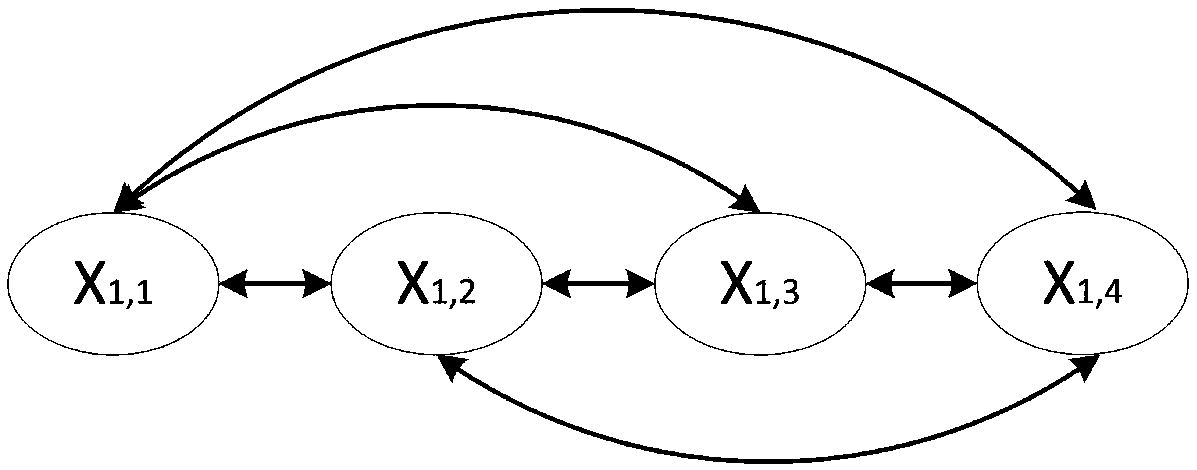

[0091] The secondary subsystem S 1 by two devices M 1 , M 2 and a buffer B 1 constitute.

[0092] 3) Determine the state law of the secondary subsystem equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com