Automatic reed buckling machine

A shrapnel machine and automatic buckle technology, applied in electrical components, electrical switches, circuits, etc., can solve the problems of low assembly efficiency, high production cost, unstable product quality, etc., and achieve the effect of reducing labor costs and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment the present invention is described in further detail.

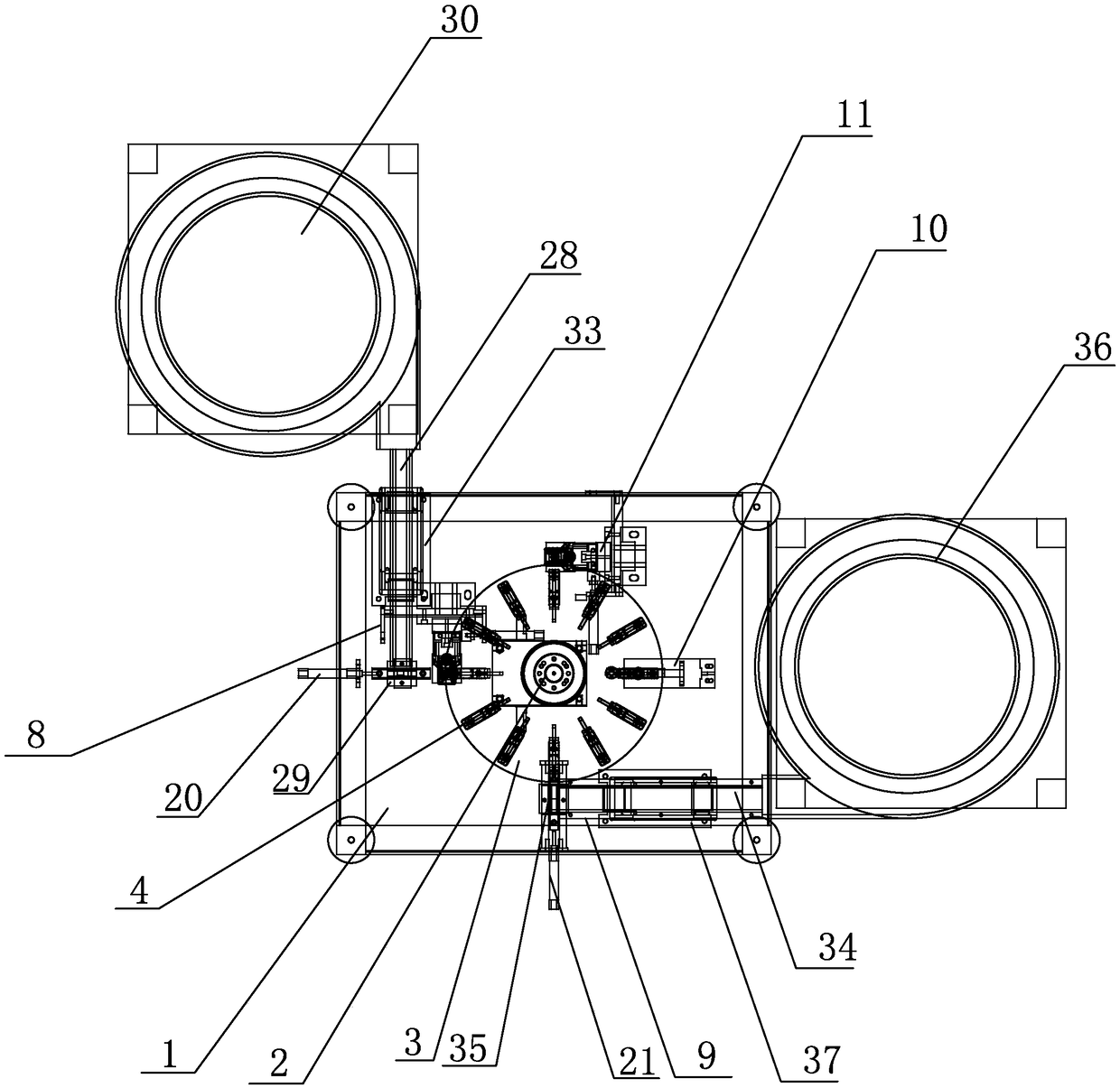

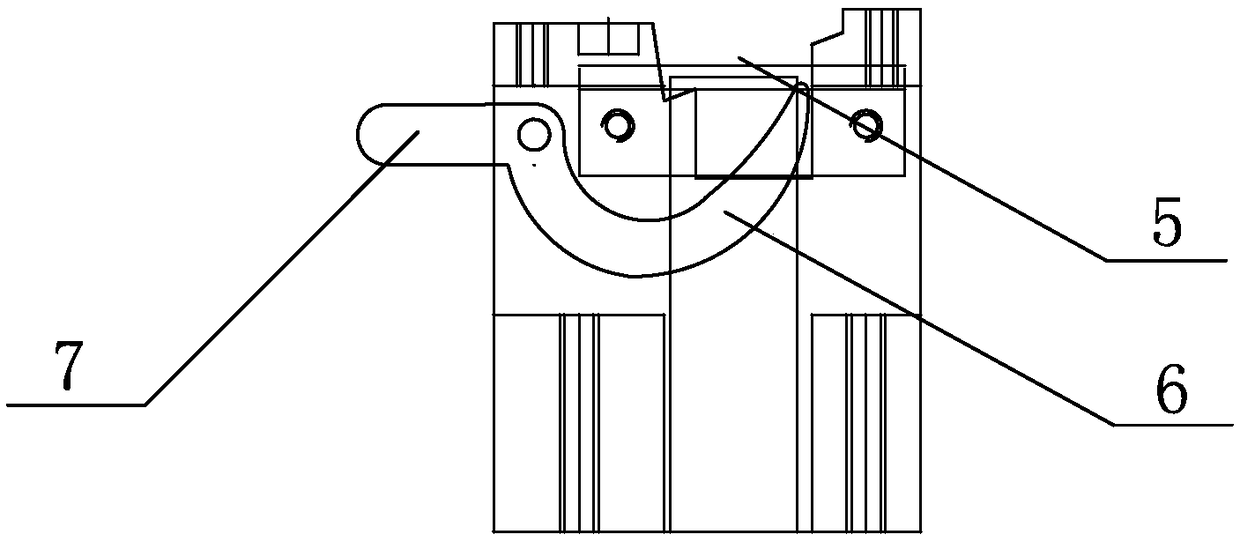

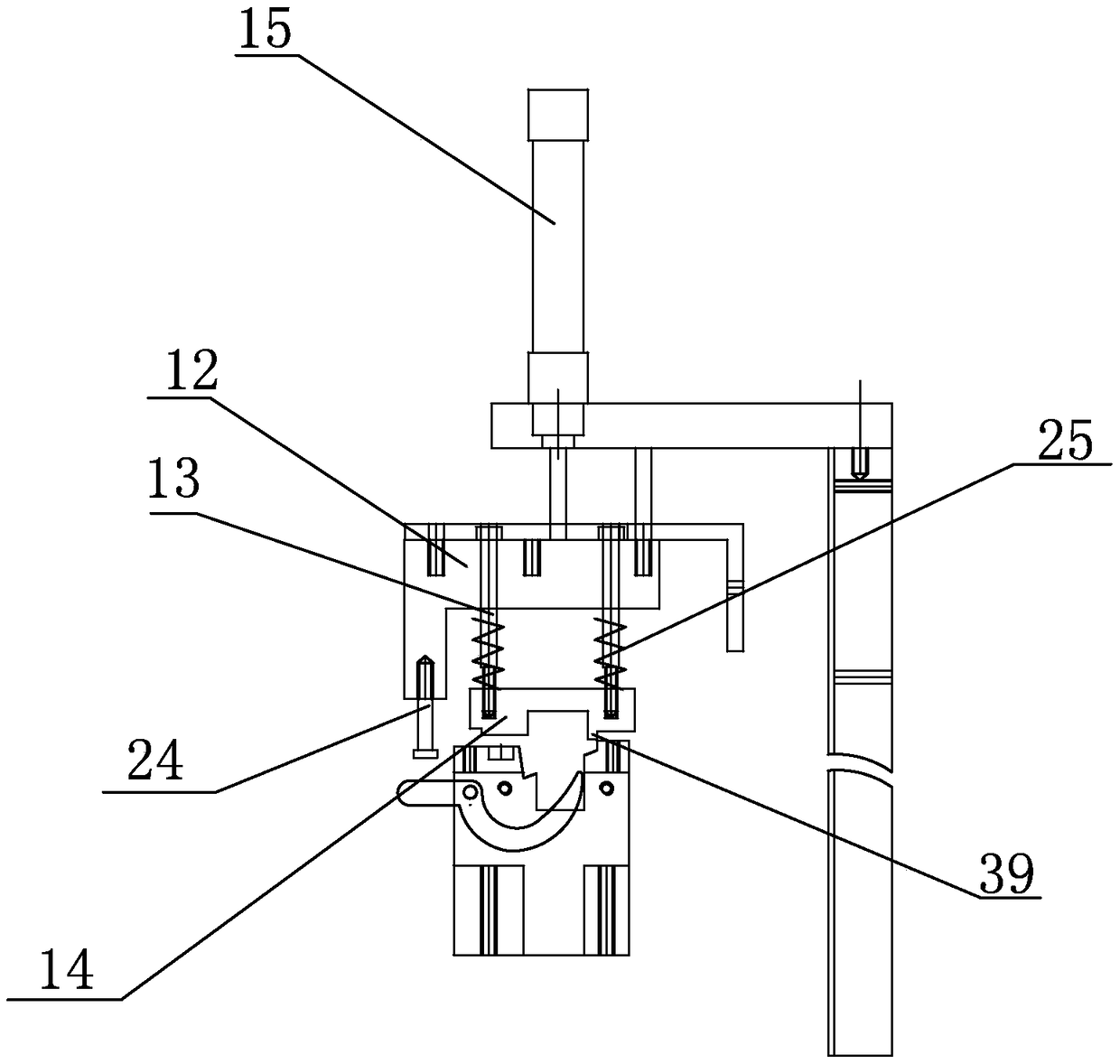

[0027] The present invention proposes an automatic shrapnel buckle machine, such as Figure 1 to Figure 8 As shown, the shrapnel buckle machine includes a base 1, a motor is fixed on the base 1, a mechanical divider 2 is connected to the motor, a disc workbench 3 is connected to the mechanical divider 2, and the disc workbench 3 is in the mechanical form. Driven by the divider 2, the gap movement at a uniform speed is realized. There are 12 clamps 4 evenly distributed along the circumferential direction of the disc worktable 3 fixed on the disc worktable 3. The clamp 4 is provided with a clamping groove 5 and the inside of the clamp 4 is hinged with a bend. Hook 6, one end of the crotch 6 is located in the clamping groove 5, the other end of the crotch 6 is provided with an extension rod 7 that extends horizontally out of the side wall of the clamp 4, and the base 1 is sequentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com