Pressing device applicable to assembly of polypropylene filter elements and operating method thereof

A polypropylene filter membrane and polypropylene technology, applied in hand-held tools, manufacturing tools, etc., can solve the problems of small number of polypropylene filter elements, poor assembly quality of polypropylene filter elements, and low work efficiency, so as to improve assembly quality, The effect of improving assembly efficiency and assembly quality and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

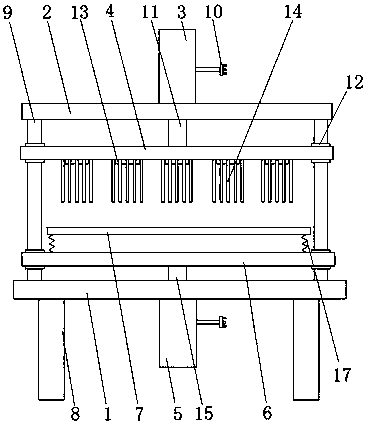

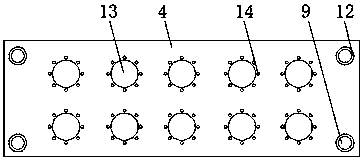

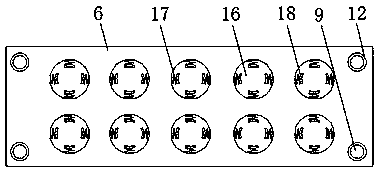

[0026] as attached Figure 1-5 As shown, a pressing device suitable for assembling a polypropylene filter element includes an operation table 1, a top plate 2, a cylinder one 3, a pressure plate 4, a cylinder two 5, a bearing plate 6 and a limit plate 7, and is characterized in that: The console 1 is arranged on the support 8, and a column 9 is vertically arranged on the console 1, the top plate 2 is arranged on the column 9, the cylinder one 3 is arranged on the top panel 2, and on the cylinder one 3 A power cord 10 and a piston rod one 11 are provided, the pressing plate 4 is arranged on the piston rod one 11, and a pressing block 13 is arranged on the pressing plate 4, the cylinder two 5 is arranged at the bottom of the console 1, and Cylinder two 5 is provided with power line 10, piston rod two 15, and described bearing plate 6 is provided with piston rod two 15, and is provided with bearing groove 16 on bearing plate 6, and described limiting plate 7 passes spring 17 is ...

Embodiment 2

[0038] as attached Image 6 As shown, a pressing device suitable for assembling a polypropylene filter element includes an operation table 1, a top plate 2, a cylinder one 3, a pressure plate 4, a cylinder two 5, a bearing plate 6 and a limit plate 7, and is characterized in that: The console 1 is arranged on the support 8, and a column 9 is vertically arranged on the console 1, the top plate 2 is arranged on the column 9, the cylinder one 3 is arranged on the top panel 2, and on the cylinder one 3 A power cord 10 and a piston rod one 11 are provided, the pressing plate 4 is arranged on the piston rod one 11, and a pressing block 13 is arranged on the pressing plate 4, the cylinder two 5 is arranged at the bottom of the console 1, and Cylinder two 5 is provided with power line 10, piston rod two 15, and described bearing plate 6 is provided with piston rod two 15, and is provided with bearing groove 16 on bearing plate 6, and described limiting plate 7 passes spring 17 is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com