Material dynamic fracture tenacity measuring device based on Hopkinson bar

A fracture toughness and measuring device technology, which is applied in the direction of measuring devices, analyzing materials, strength characteristics, etc., can solve the problems of difficult measurement of dynamic fracture toughness, inertial effect and stress wave propagation law, and can not be achieved, so as to achieve stable loading means Reliable, guaranteed geometric stability, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

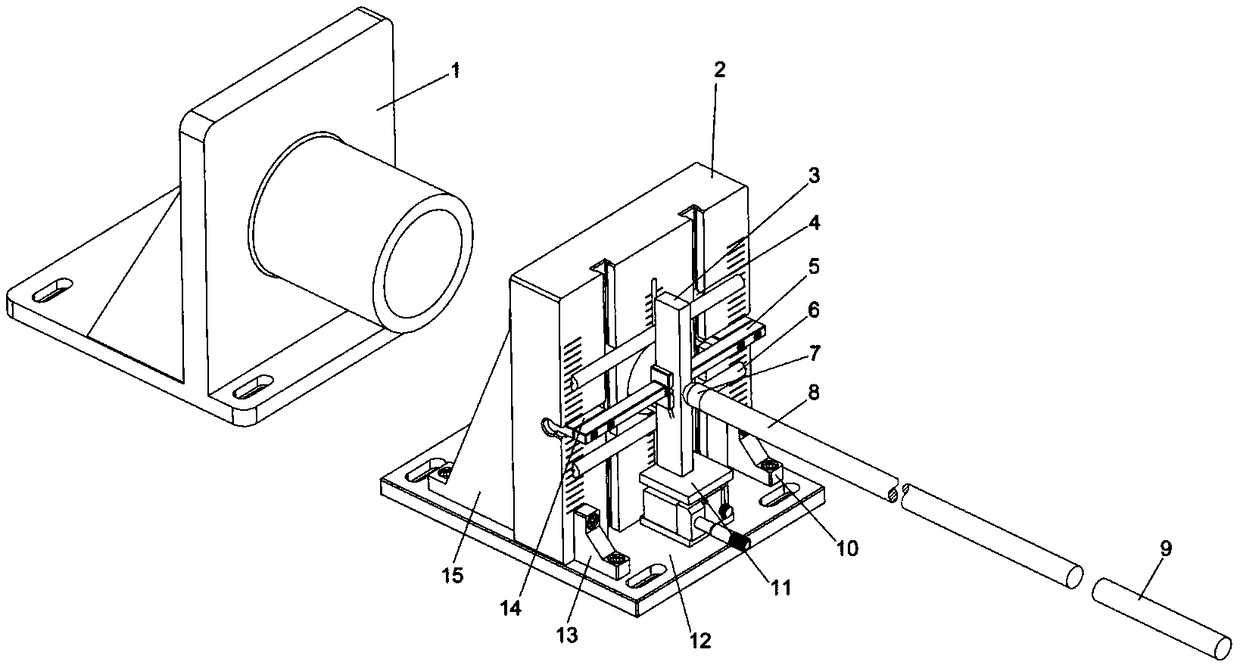

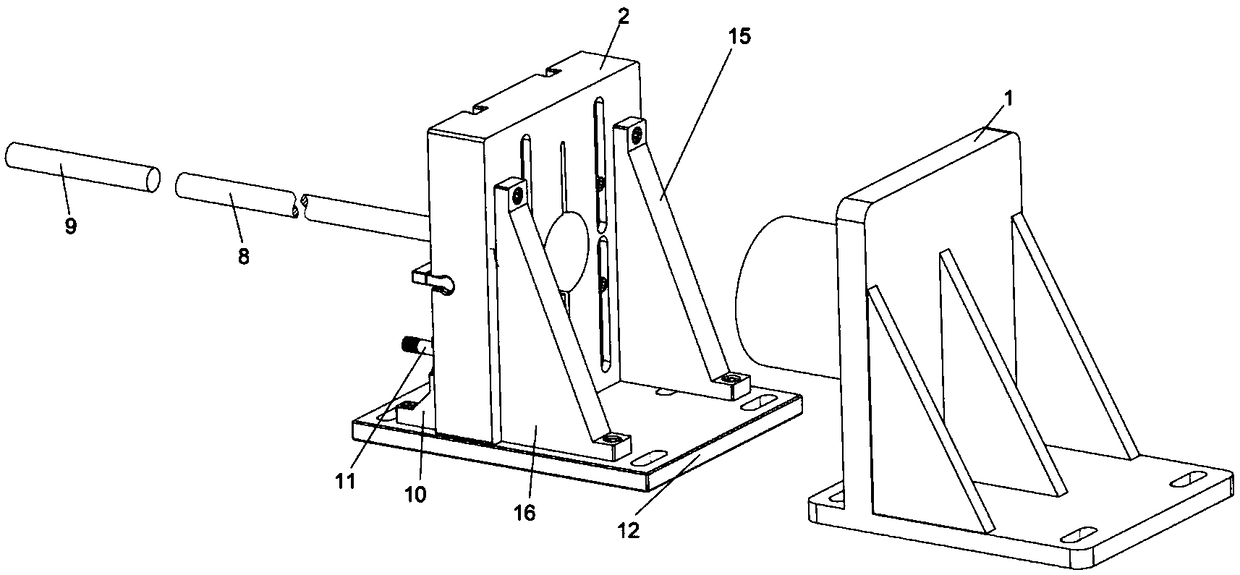

[0042] Such as figure 1 and figure 2 As shown, a material dynamic fracture toughness measurement device based on a Hopkinson rod, including a buffer device, a load-bearing device, a Hopkinson rod experimental device, a shooting device and a sample with a notch;

[0043] The carrying device includes a base plate 12, a vertical plate 2 and a lifting displacement platform 11, the vertical plate 2 and the lifting displacement platform 11 are fixedly installed on the base plate 12, and the sample 3 is placed on the lifting displacement platform 11;

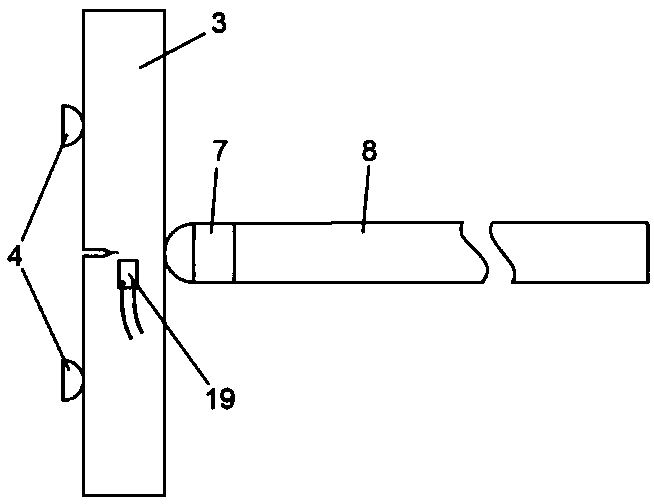

[0044]Two parallel vertical chute 2.2 and two horizontal chute 2.1 on the same horizontal line are provided on the side of the vertical plate 2 adjacent to the sample; the vertical plate 2 is provided with two strips for supporting the sample shaped semicircle bearing 6, the arc surface of strip sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com