Impact wear testing device capable of simulating sand and high-temperature complex environments

A complex environment, wear test technology, used in measuring devices, testing wear resistance, instruments, etc., can solve the problems of impact wear, inaccurate punch speed, complex impact wear behavior, etc., to achieve precise control, consistent impact speed , the effect of precise impact movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

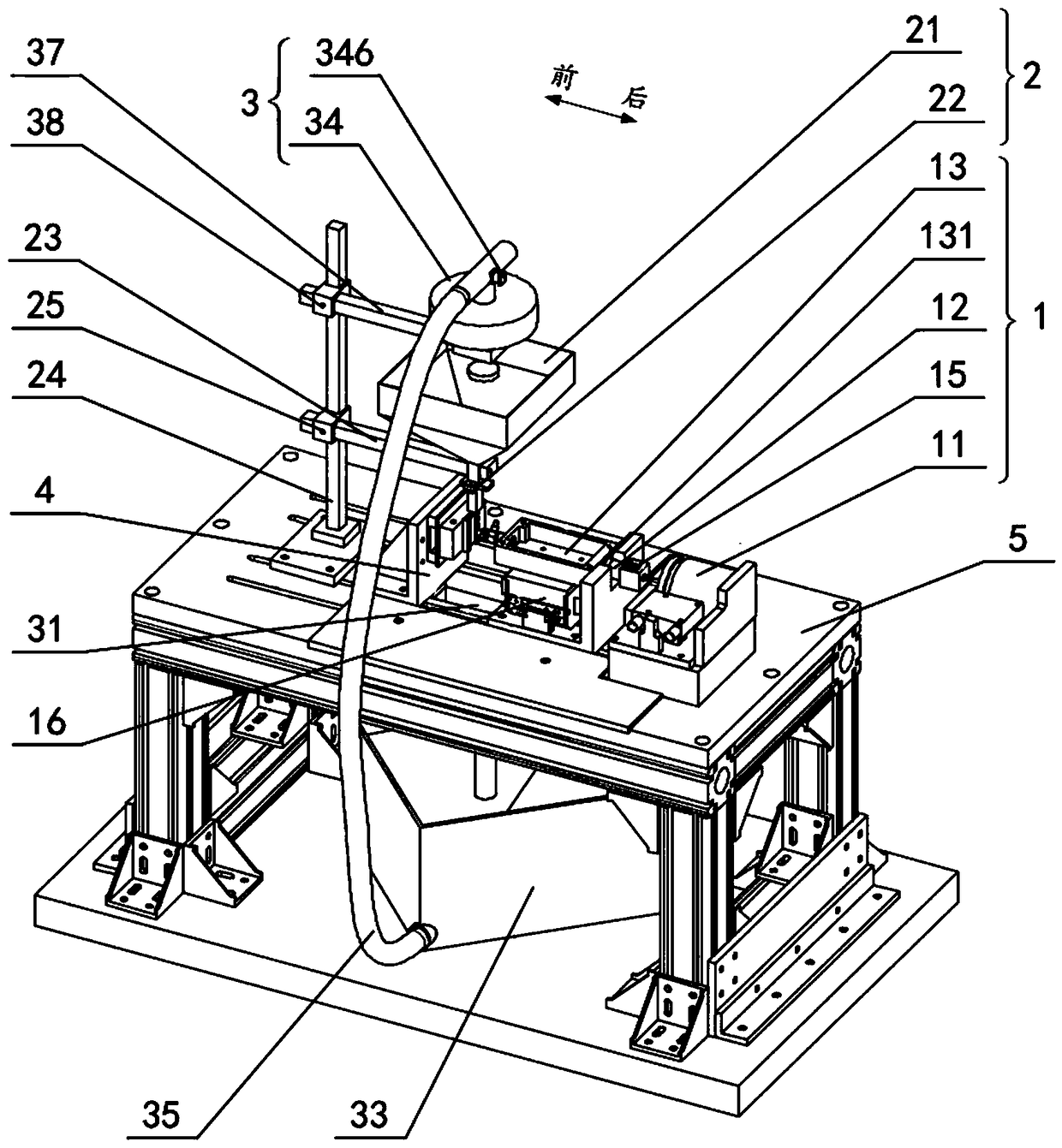

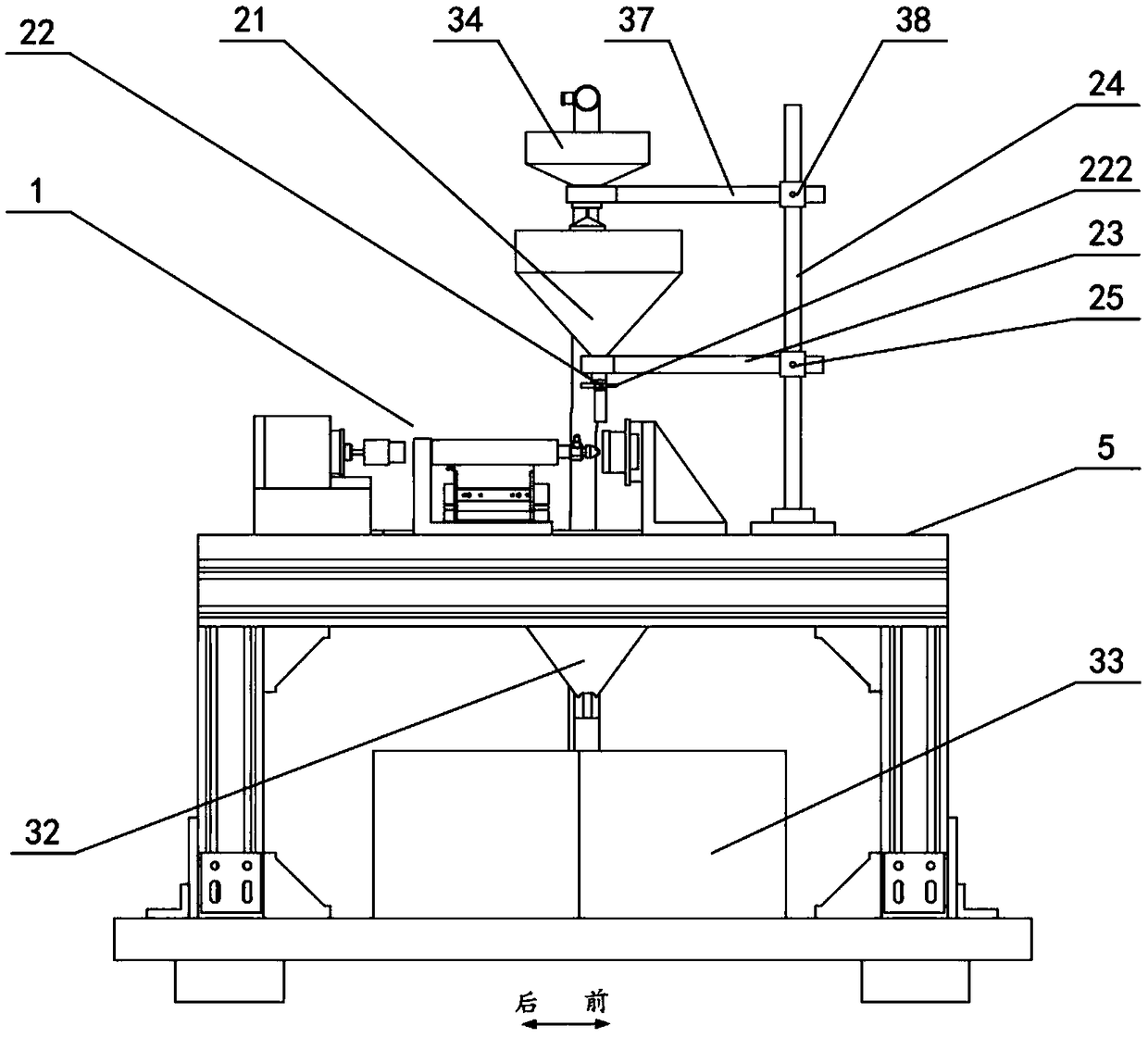

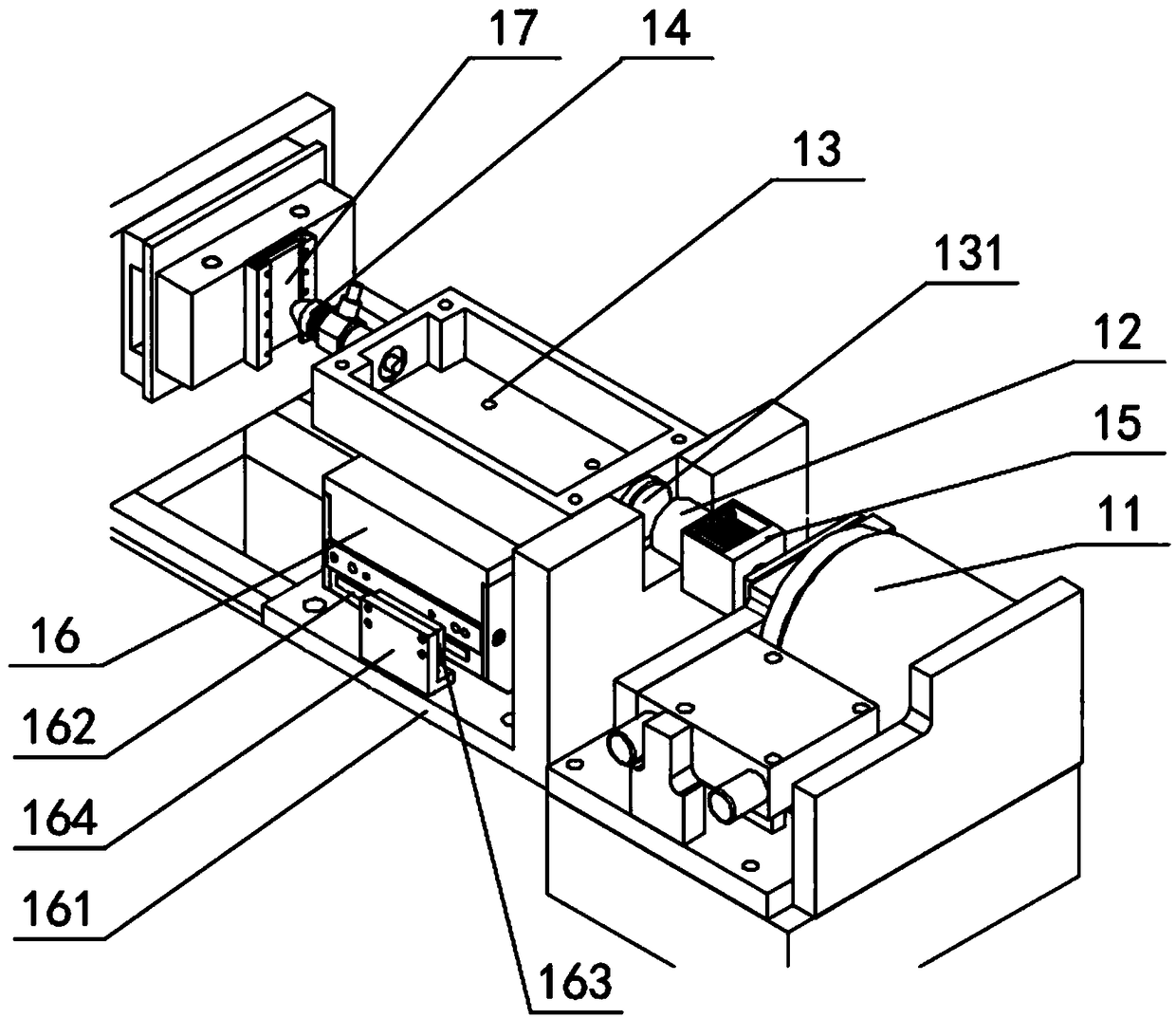

[0054] Such as Figure 1-11 As shown, the impact and wear test device capable of simulating sand particles and high-temperature complex environments provided in this embodiment includes an impact mechanism 1, a sand delivery mechanism 2, an automatic sand circulation mechanism 3, a sample heating mechanism 4 and the installation of the aforementioned mechanisms The frame 5; the impact mechanism 1 includes a linear drive motor 11, an impact electric chuck 12, a punch mounting base 13 and a punch clamp 14 arranged in sequence from back to front, wherein the linear drive motor 11 is used for Drive the impact electric chuck 12 to make linear reciprocating motion in the front and rear direction, and the impact electric chuck 12 is used to make the punch mounting base 13 also perform linear reciprocation in the front and rear direction through the way of electrification to magnetize / down power to degauss The punch installation base 13 is used to install the punch clamp 14 on the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com