An impact wear test device capable of simulating sand and high temperature complex environment

A complex environment and wear test technology, applied in the direction of measuring devices, wear resistance testing, instruments, etc., can solve the impact of impact wear, inaccurate punch speed, complex impact wear behavior, etc., to achieve precise control and consistent impact speed , the effect of precise impact movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

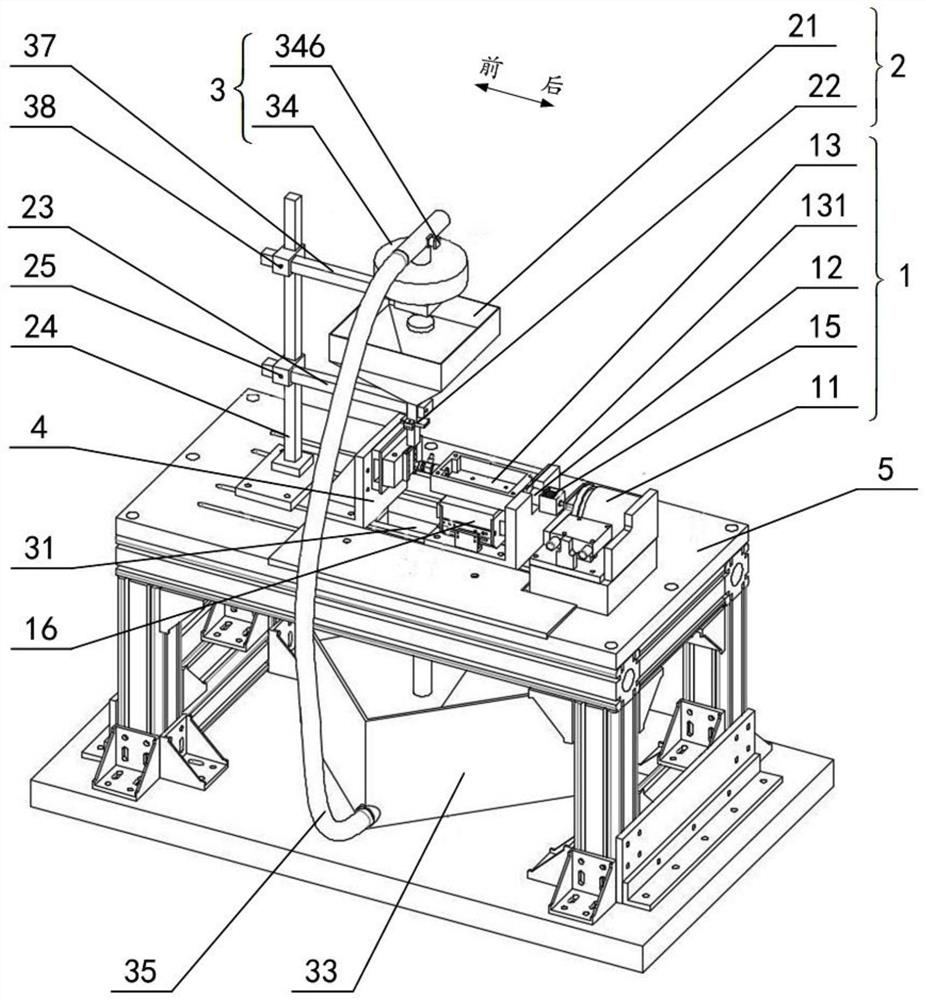

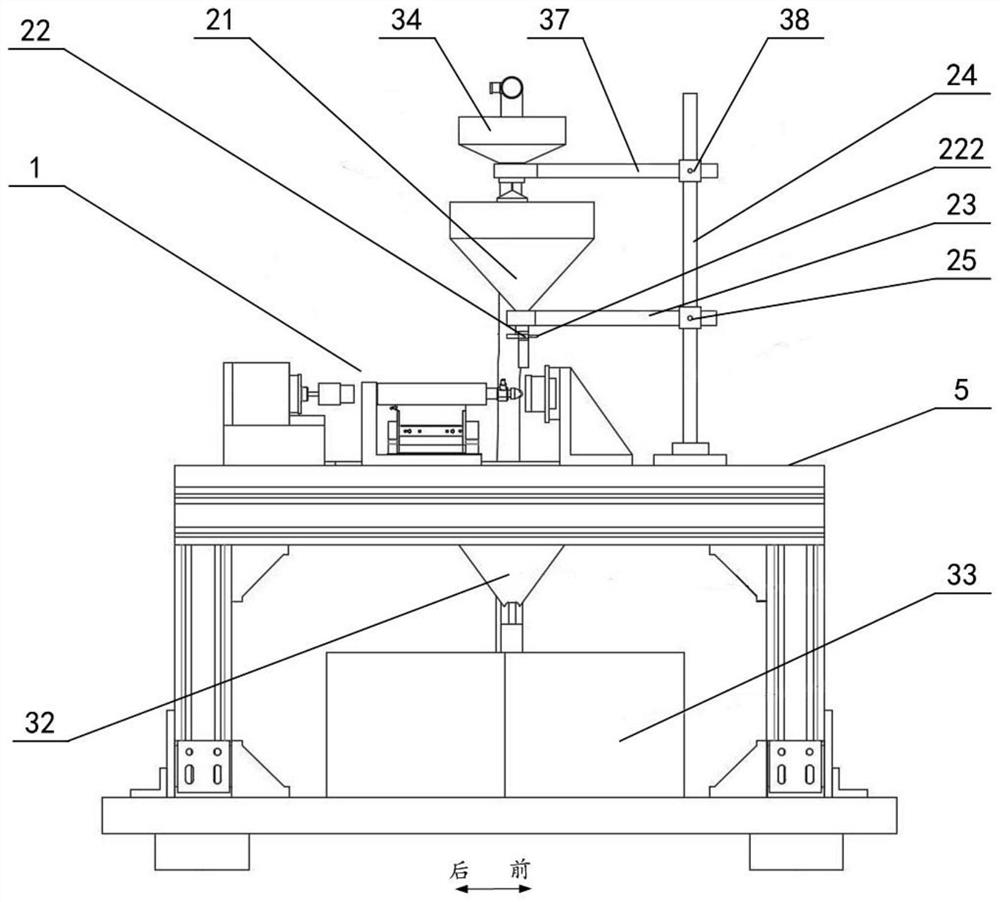

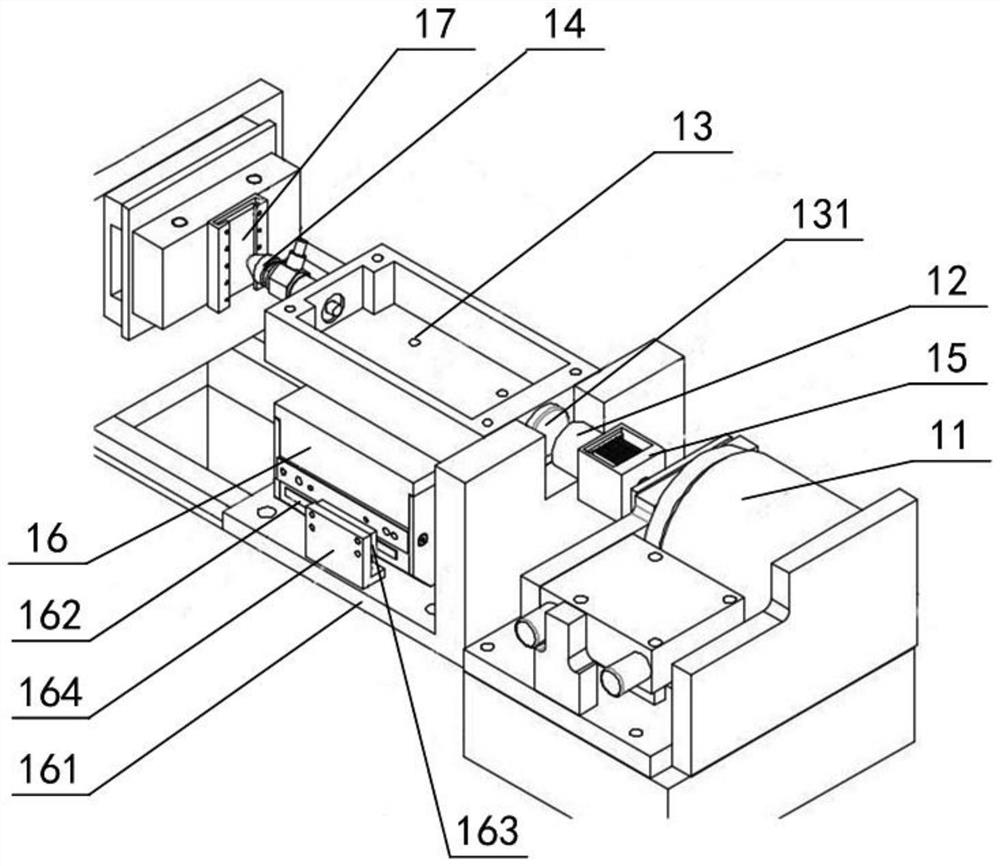

[0054] Such as Figure 1 ~ 11 As shown, the impact wear test device capable of simulating sand and high temperature complex environments, including impact mechanism 1, sewing mechanism 2, sand automatic circulating mechanism 3, sample heating mechanism 4, and installing the aforementioned mechanism Rack 5; the impact mechanism 1 includes a straight drive motor 11, a shock electric suction cup 12, a punch mounting base 13 and a punch fixture 14, wherein the linear drive motor 11 is used for Driveing the impact electroacup plate 12 in front and rear direction, a linear reciprocating motion, the impact electric suction cup 12 is used to make the punch mounting base 13 in the front and rear direction by the upper and rear direction by the upper and rear direction. Movement, the punch mounting base 13 is used to mount the punch fixture 14 at the front end surface; the sand mechanism 2 includes a sand funnel 21 and a sandflow speed control valve 22, wherein the sand funnel 21 is dispos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com