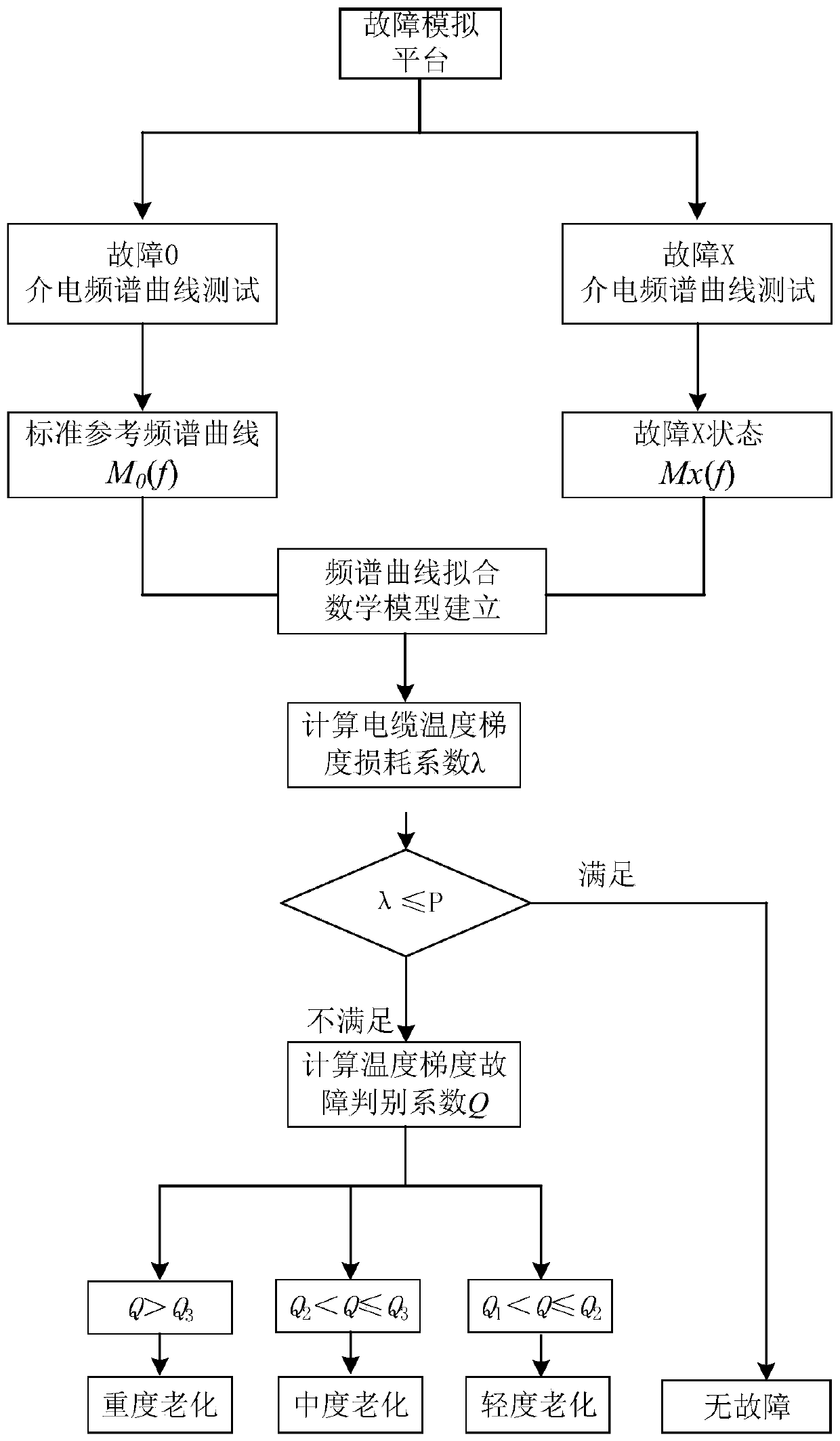

A Method for Simulating and Testing Cable Radial Damage Fault Under Temperature Gradient

A technology of temperature gradient and test method, applied in the direction of fault location, fault detection according to conductor type, etc., to achieve the effect of accurate damage degree judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with embodiment.

[0047] The implementation cases are as follows:

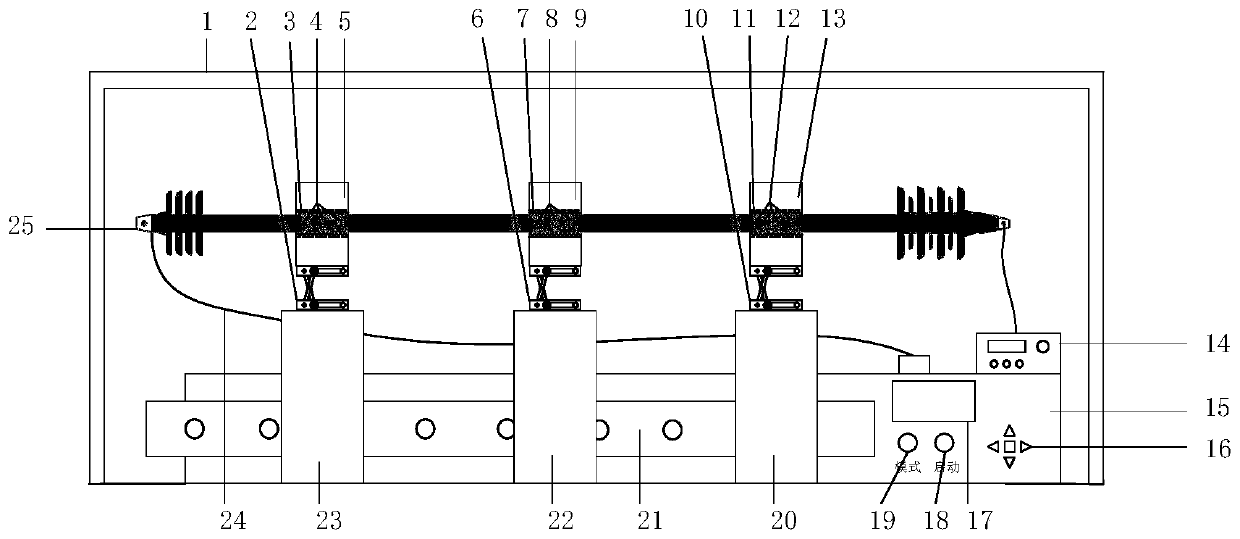

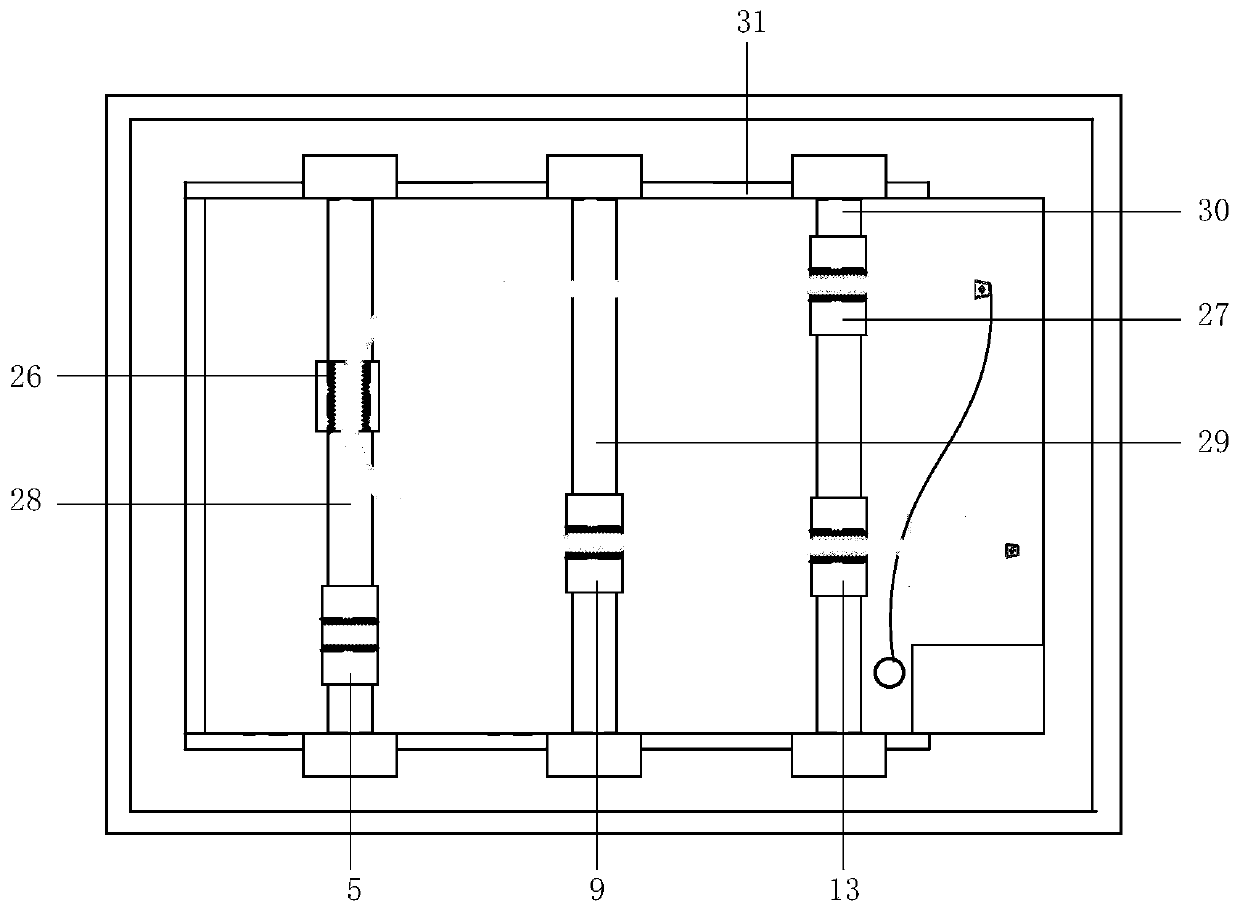

[0048] figure 1 Shown is the cable radial damage fault simulation device under temperature gradient, including shielding shell (1), height adjuster 1 (2), cooling assembly 1 (3), temperature sensor 1 (4), U-shaped clamp 3 (5) , height adjuster 2(6), cooling assembly 2(7), temperature sensor 2(8), U-shaped clamp 2(9), height adjuster 3(10), cooling assembly 3(11), temperature sensor 3( 12), U-shaped fixture 1 (13), DC current source (14), console (15), selection button (16), display screen (17), start button (18), mode selector (19), the first A support assembly (20), left lateral slide rail (21), right lateral slide rail (31), second support assembly (22), third support assembly (23), data collection line (24), cable to be tested ( 25), U-shaped clamp 4 (26), U-shaped clamp 5 (27), longitudinal sliding rod 1 (28), longitudinal slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com