A Simulation Platform for Cable Radial Insulation Damage in Humid Environment

A damage simulation, wet environment technology, applied in the direction of measuring electricity, measuring electrical variables, testing dielectric strength, etc., can solve the problem of not being able to detect the ability of the cable to resist radial damage well, and achieve the effect of accurate judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

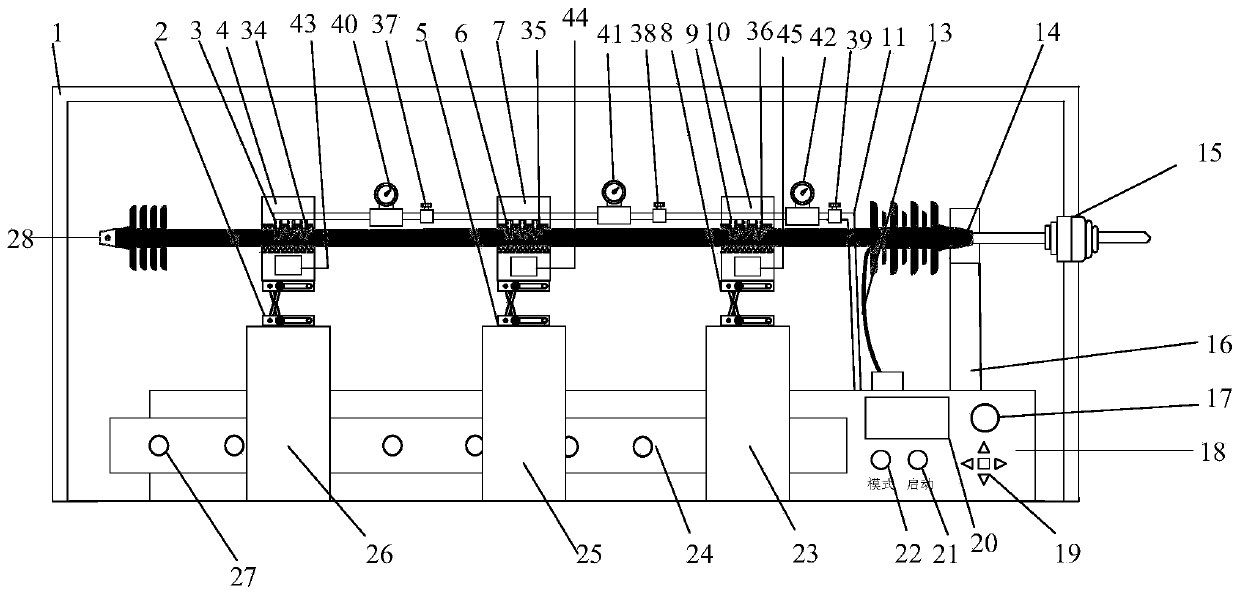

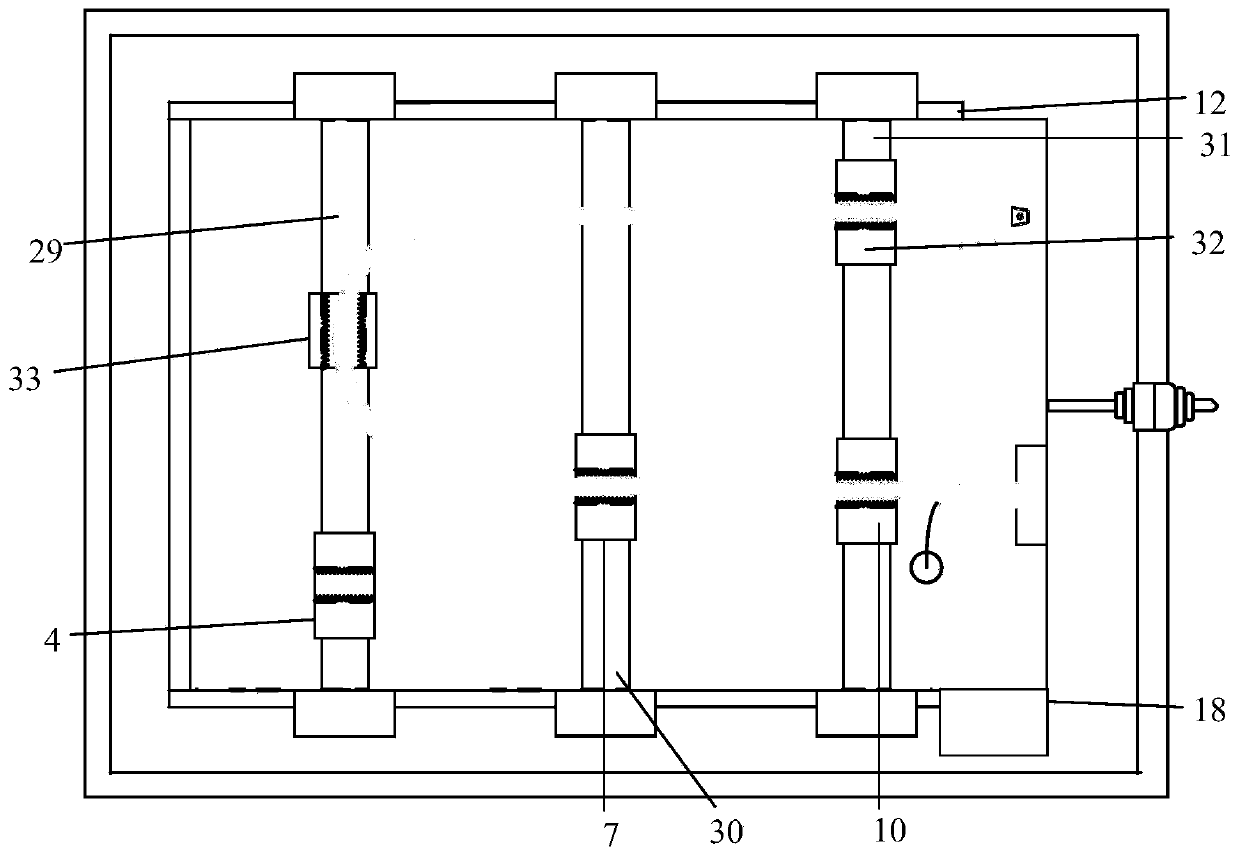

[0011] figure 1 Shown is a schematic diagram of the cable radial insulation damage simulation platform in a humid environment according to the present invention, figure 2 Shown is a top view of the cable radial insulation damage simulation platform in a humid environment according to the present invention. Radial local moisture damage simulation platform includes shielding shell 1, lifting platform 2, wedge-shaped hollow acupuncture assembly 3, U-shaped fixture 4, lifting platform 5, wedge-shaped hollow acupuncture assembly 6, U-shaped fixture 7, lifting platform 8, wedge-shaped hollow Acupuncture assembly 9, U-shaped clamp 10, U-shaped clamp 32, U-shaped clamp 33, signal line 11, signal transmission test line 13, cable terminal input port 14, high-voltage bushing 15, connection test bench 16, start indicator light 17 , platform controller 18, selection button 19, control display 20, start button 21, mode setting button 22, first support assembly 23, left lateral slide track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com