Automatic temperature and humidity control method for airtight cabinet based on temperature feedback

A technology of temperature and humidity control and temperature feedback, which is applied in the direction of non-electric variable control, control/regulation system, and simultaneous control of multiple variables. The effect of rapid stabilization of temperature and humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

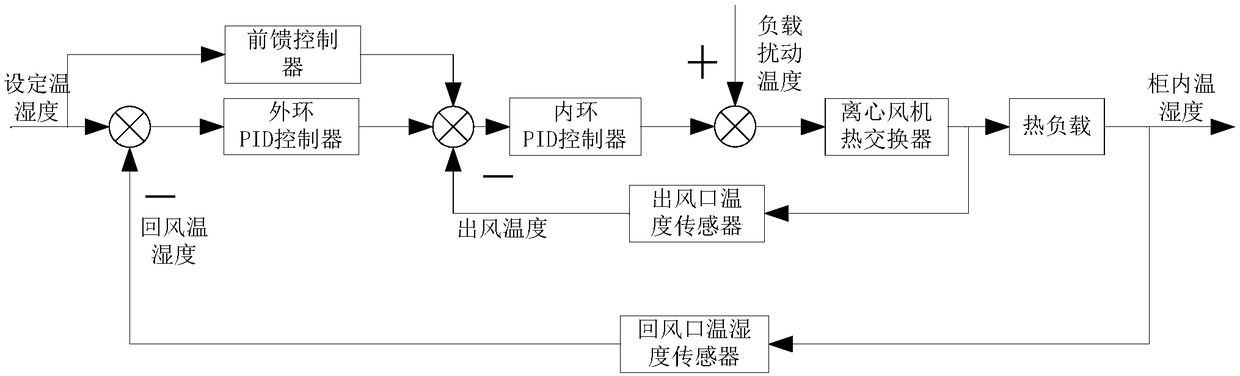

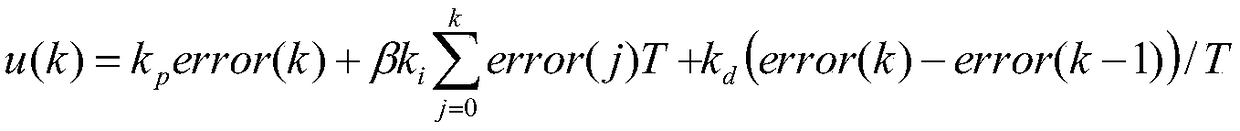

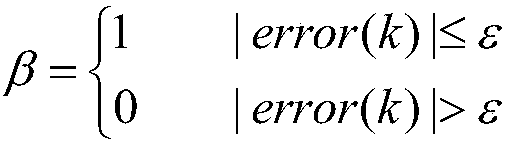

[0011] The present invention combines the advantages of feedforward compensation control technology and cascaded PID control technology, adopts integral separation PID control algorithm, adjusts the speed of centrifugal fan according to the real-time heating power of each cabinet, automatically corrects the input cooling capacity, and ensures the stability of the temperature inside the cabinet in the set value.

[0012] For the temperature and humidity control system, how to ensure that the temperature fluctuation inside the airtight cabinet is less than the temperature and humidity threshold is the core of the design of this control algorithm. Due to the large range of load variation of the internal components of the cabinet, the heat generated by it also fluctuates within a large range (1.5kW ~ 4.5kW), so how to quickly, accurately and stably track the change of heat load inside the cabinet, and ensure that the temperature and humidity inside the cabinet are stable at the set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com