A method for positioning and identifying pointer instruments based on machine vision

A machine vision and recognition method technology, applied in character and pattern recognition, instruments, computer parts, etc., can solve the problems of high requirements for image clarity and strong contrast, difficult to obtain dial information, difficult to obtain scale information, etc. Achieve accurate and reliable identification results, avoid the influence of interference factors, and improve the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Below in conjunction with example the present invention is described in detail:

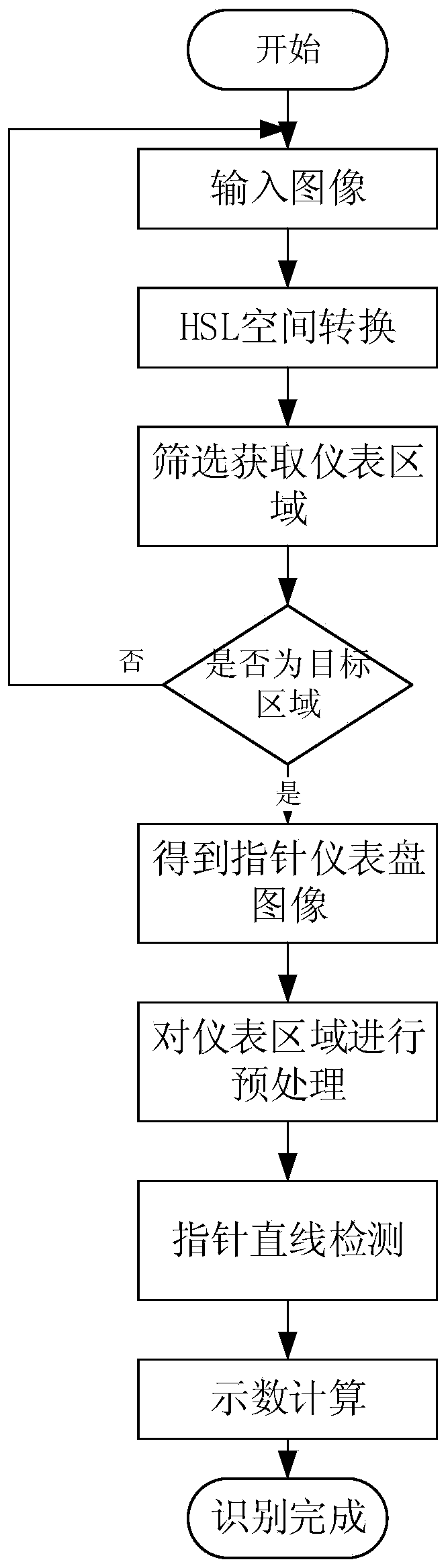

[0058] Such as figure 1 As shown, the pointer instrument positioning and identification method based on machine vision of the present invention comprises the following steps:

[0059] (1) Obtain the image of the instrument cabinet (note: the instrument panel is located on the surface of the instrument cabinet):

[0060] Capture images of the instrument cabinet with a digital camera or video camera.

[0061] (2) Segment the image of the instrument cabinet to obtain the image of the instrument panel, as follows:

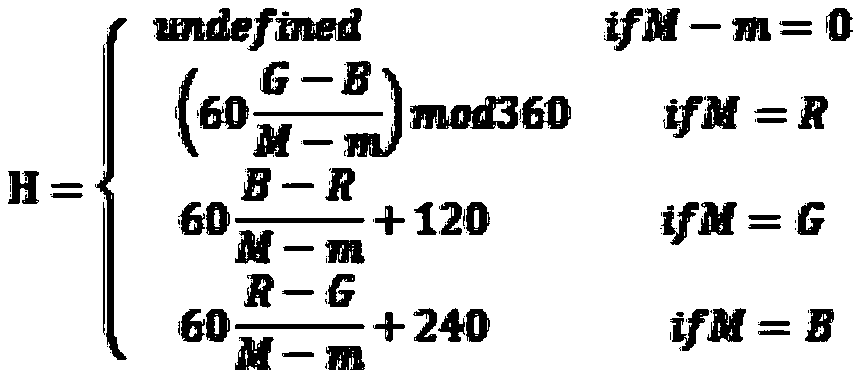

[0062] A. Convert the image of the instrument cabinet from RGB to HSL. The specific conversion formula is as follows:

[0063]

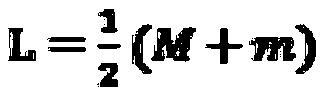

[0064]

[0065]

[0066] Wherein, M=max(R,G,B), m=min(R,G,B).

[0067] B. Binarize the luminance map of the instrument cabinet. The L component of the HSL space image is extracted to obtain the brightness map of the instrument cabinet. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com