Transmission device and transmission control method

A transmission device and sensor technology, applied in transportation and packaging, thin material handling, function indication, etc., can solve problems such as complex operation and unstable tension control, and achieve high stability, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

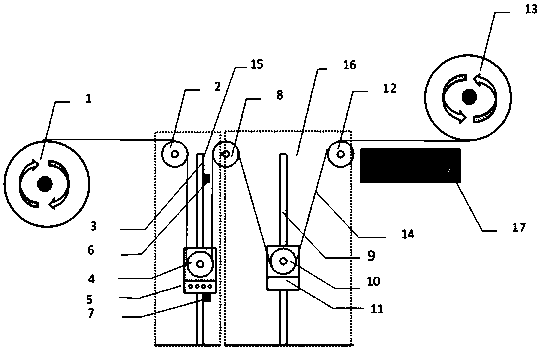

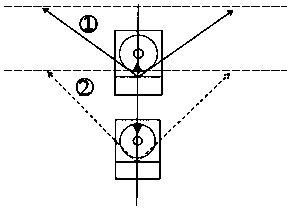

[0031] This embodiment relates to a transmission device for roll-to-roll transmission of strips, such as figure 1 As shown, it mainly includes a horizontally placed unwinding shaft 1 and a winding shaft 13, and also includes a first guide wheel 2 connected to the unwinding shaft 1, a third guide wheel 12 connected to the winding shaft 13, and a first guide wheel 2 located on the first guide wheel 2. and the second guide wheel 8 between the third guide wheel 12, wherein an adjustment mechanism 15 is arranged between the first guide wheel 2 and the second guide wheel 8, and an adjustment mechanism 15 is arranged between the second guide wheel 8 and the third guide wheel 12 There is a buffer mechanism 16; the adjustment mechanism 15 includes a vertically placed first guide rod 3 and a first movable runner 4 that can move up and down along the first guide rod 3, and the strip 14 passing through the first movable runner 4 Parallel to the first guide rod 3; the buffer mechanism 16 i...

Embodiment 2

[0038] This embodiment relates to a transmission control method, refer to the attached figure 1 , first place the strip on the unwinding shaft 1, and then pass through the first guide wheel 2, the first movable wheel 4, the second guide wheel 8, the second movable wheel 10, the third guide wheel 12 and the console 17 is wound on the take-up reel 13.

[0039] The transmission control method in this embodiment includes the following steps:

[0040] Step 1, start the unwinding shaft 1, the first movable wheel 4 and the first weight 5 move downward along the first guide rod 3 as a whole, and the second movable wheel 10 and the second weight 11 move along the second guide rod 9 moves down, when the first movable runner 4 and the first weight 5 move at a constant speed, the second movable runner 10 and the second weight 11 move up to the initial state along the second guide rod 9, and the lower end position When the induction detector 7 detects that the first movable wheel 4 reaches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com