A kind of protection device for top angle of shell structure

A technology of shell structure and protection device, which is applied in the direction of packaging, transportation and packaging, and containers to prevent mechanical damage. It can solve the problems of easy damage of rubber protective pads, easy falling off of protective pads, and failure of protection, etc., to protect the shell structure. The effect of top corner, good shell structure top corner, good cushioning force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

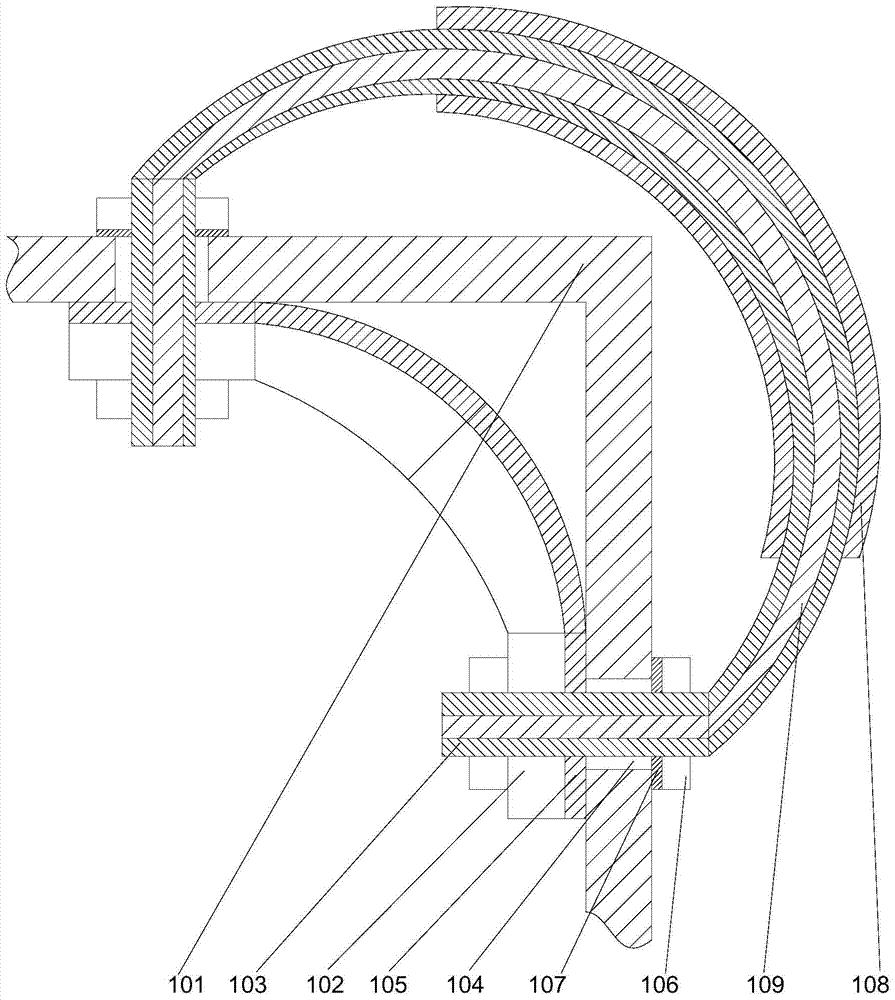

[0020] Such as figure 1 As shown, a shell structure corner protection device includes a support base 102 arranged inside the shell structure 101 and a support tube 103 set outside the shell structure 101, and the two ends of the support tube 103 are respectively located at the On the two side walls of the shell structure 101, the middle part of the support tube 103 is bent away from the support base 102 to form an arched structure, and two sets of through holes are arranged on the shell structure 101 The structure 104 is provided with external threads at both ends of the support pipe 103, and the two ends of the support pipe 103 pass through the through-hole structure 104 and are screwed on the ground support base 102. A cushion layer 105 is provided on the side of the base 102 facing the inner wall of the shell structure 101, and a lock nut 106 is set on the end of the support tube 103 close to the shell structure 101. 106 is provided with a rubber cushion 107 on the side fa...

Embodiment 2

[0023] In this embodiment, on the basis of Embodiment 1, in order to improve the impact resistance of the support tube, in this embodiment, preferably, an anti-skid rubber 108 is set in the middle of the support tube 103, and the outer wall of the anti-skid rubber 108 is There are anti-slip embossed on it. By setting anti-slip rubber and anti-slip embossed structure, the friction force between the support tube and the external structure can be increased, so that when it is impacted by an external force, it is not easy to drive the entire shell structure to tilt, which helps to improve the shell structure. structural stability.

[0024] Further preferably, in order to facilitate installation and prevent the anti-slip rubber from falling off at high temperature, in this embodiment, the inner wall of the anti-slip rubber 108 is coated with a high-temperature resistant resin adhesive, and the inner wall of the anti-slip rubber 108 passes through The high temperature resistant res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com