S-shaped cutting seam cartridge and production method thereof

A production method and cutting technology, which is applied in blasting and other directions, can solve the problem that the crushing effect of rock mass cannot be optimally controlled, and achieve the effect of improving loading and unloading rate and reducing block rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

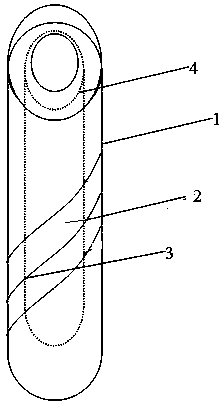

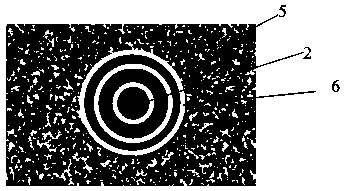

[0027] Combine below figure 1 with figure 2 , to further illustrate the present invention.

[0028] As shown in the figure, an S-shaped slotted charge includes a blasthole and a slotted tube 1 located in the blasthole, the slotted tube 1 is filled with explosives 2; the tube wall of the slotted tube 1 There are several equidistant S-shaped slits 3 on the top, and the S-shaped slits 3 are located on one side of the slit pipe. There is an S-shaped slit 3 on the slit pipe 1. At the moment of explosive blasting, a high-pressure gas jet is first generated, and then through the energy gathering of the S-shaped slit, an S-shaped water jet is formed, and then impacts the wall of the blast hole to achieve the directional fracture of a specific rock. Purpose. The S-shaped slit is located on one side of the slit tube, which can ensure that the jet formed after energy gathering is ejected according to the predetermined plan.

[0029] In order to ensure that the slit cartridge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com