Tensile shielding insulating cable for charging pile

A technology of shielding insulation and charging piles, applied in the field of tensile shielding insulated cables for charging piles, can solve the problems of shortened service life of charging pile cables, poor cable tensile strength and mechanical properties, etc. The effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

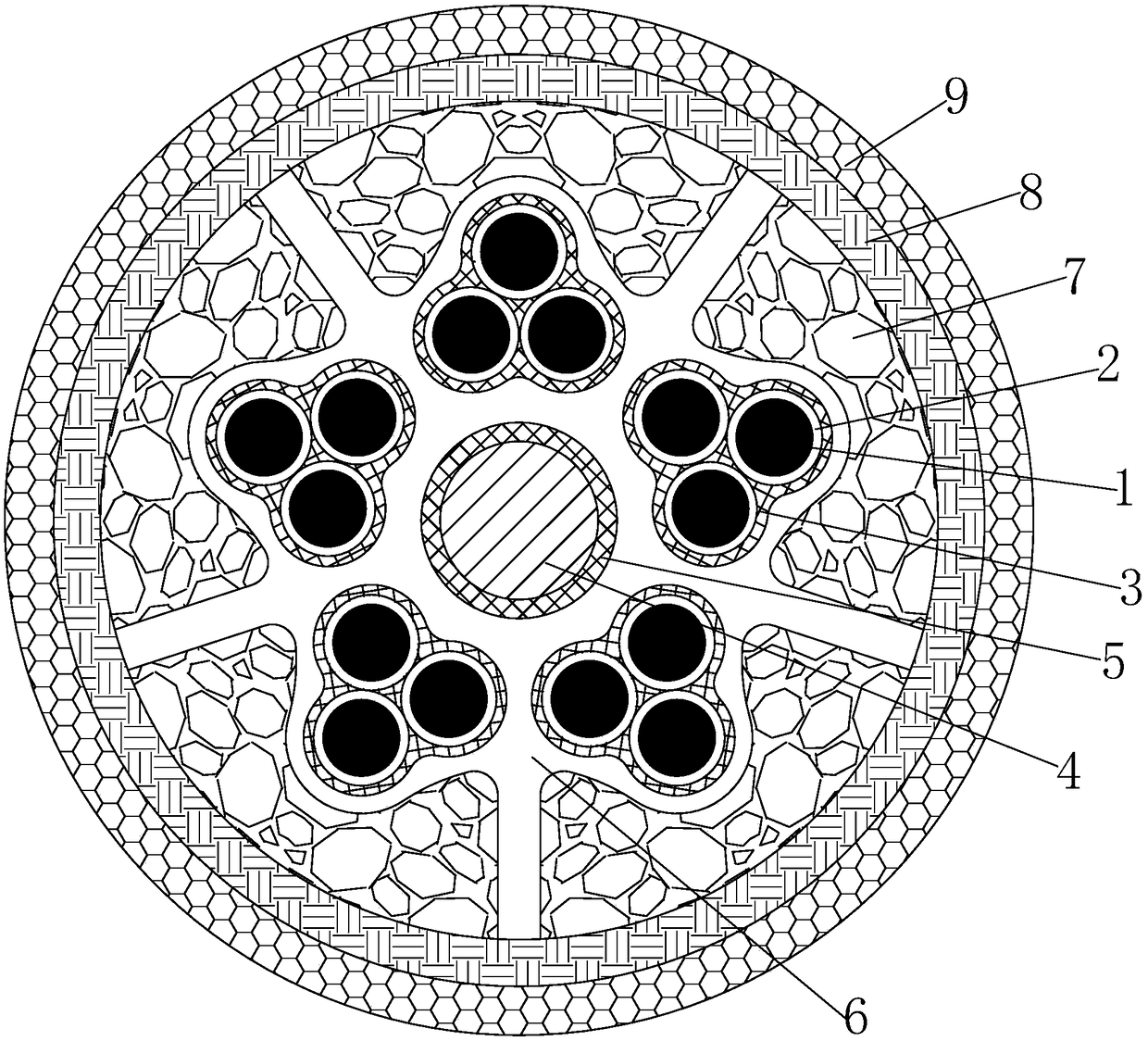

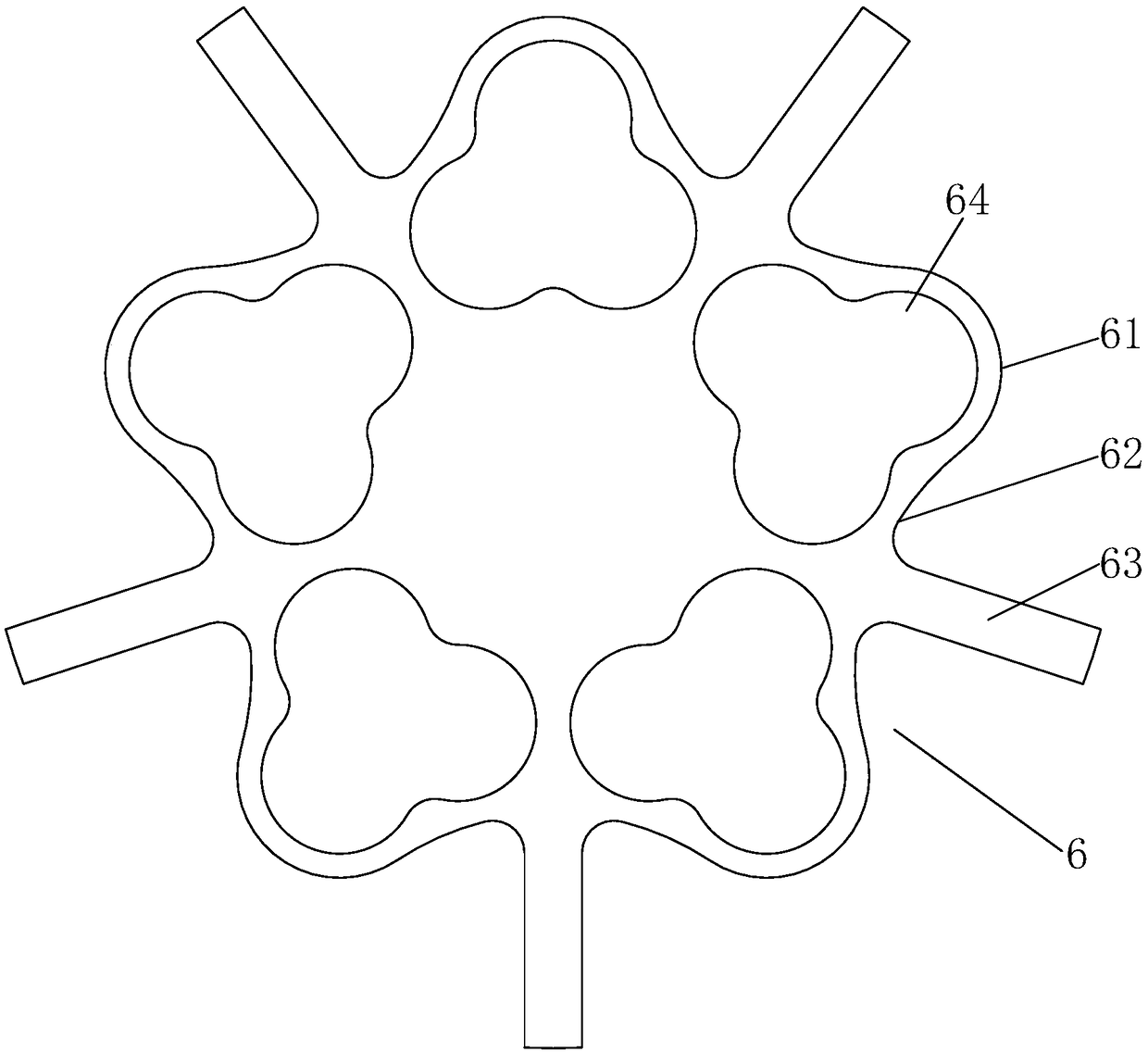

[0022] Such as Figure 1 to Figure 2 As shown, a tensile shielded insulated cable for a charging pile includes a wire core wrapping group and a control wire core wrapping group. "Product" shape twisted, the first shielding layer 3 is wrapped outside the core package group, the core includes a conductor 1, and an inner insulating layer 2 wrapped outside the conductor 1; the core package group is composed of The advantage of twisting the three wire cores in the shape of a "pin" is that its tensile capacity is enhanced, and it will not be easily broken during frequent pulling.

[0023] The control wire core package group is composed of the control wire core 4 arranged at the center of the cable and the second shielding layer 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com