Elastic hook heat sink structure

A heat sink and hook type technology, applied in the field of the hook type heat sink structure, can solve the problems of affecting the heat dissipation effect, the deflection of the heat sink, the inability of the chip and the heat sink to fit, etc., and achieve the effect of improving the assembly deflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

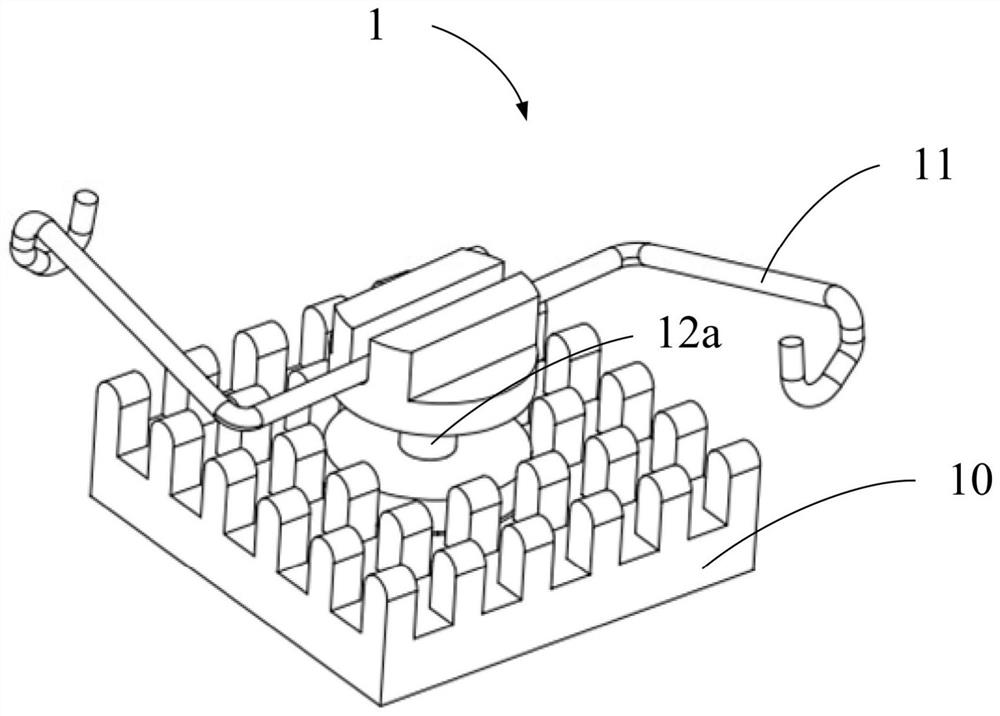

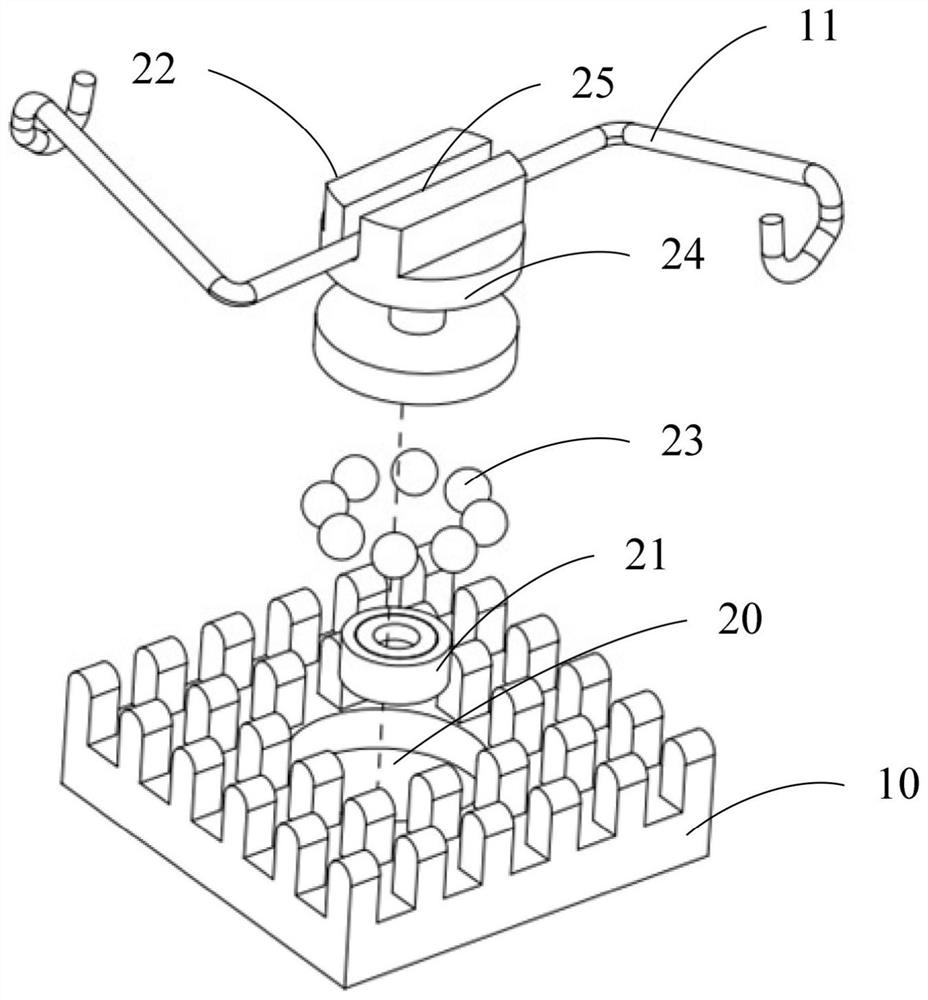

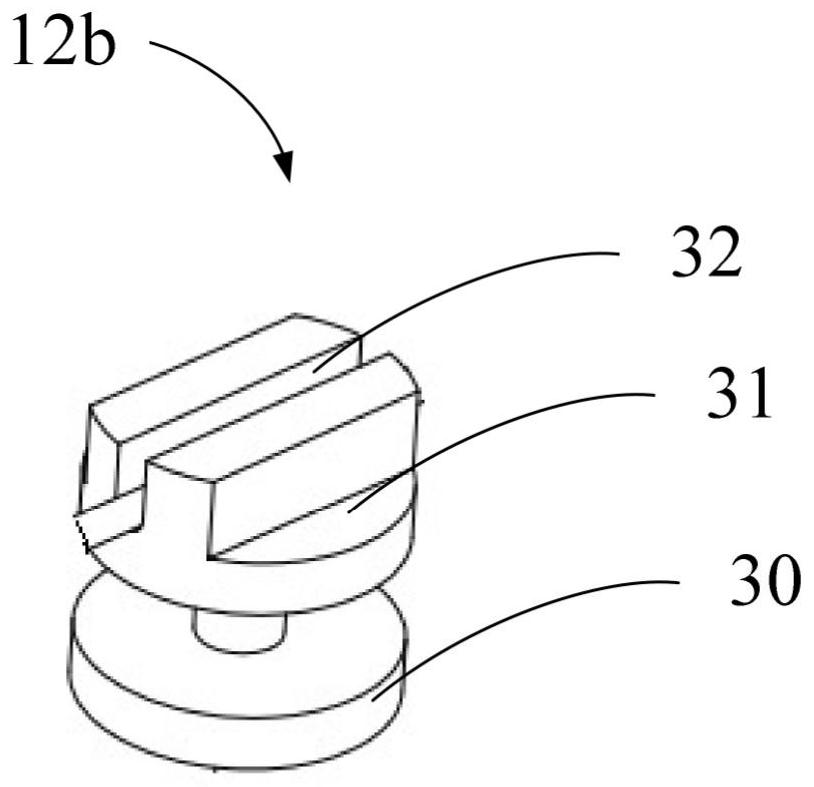

[0041] refer to figure 1 , figure 1 It is a schematic diagram of the snap-hook heat sink structure 1 of the embodiment of the present invention. The spring-hook heat sink structure 1 includes a heat sink 10 , a spring hook 11 and a rotating shaft 12 a. One end of the rotating shaft 12 a is connected to the heat sink 10 , and the other end is connected to the spring hook 11 , and the spring hook 11 can rotate along the rotating shaft 12 . That is to say, in this embodiment, the rotating shaft 12a can rotate, and the rotating shaft 12 will not drive the heat sink 10 connected thereto to rotate.

[0042] The spring-hook type heat sink structure 1 provided in the embodiment of the present invention replaces the existing method of directly riveting the spring hook 11 to the body of the heat sink 10 by connecting the rotating shaft 12 a to the spring hook 11 . Since the spring hook 11 is connected to the rotatable shaft 12a, the body of the heat sink 10 will only be subjected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com