Amplitude changing device special for quadrilateral steel plate

A quadrilateral and steel plate technology, applied in the field of special luffing devices for quadrilateral steel plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

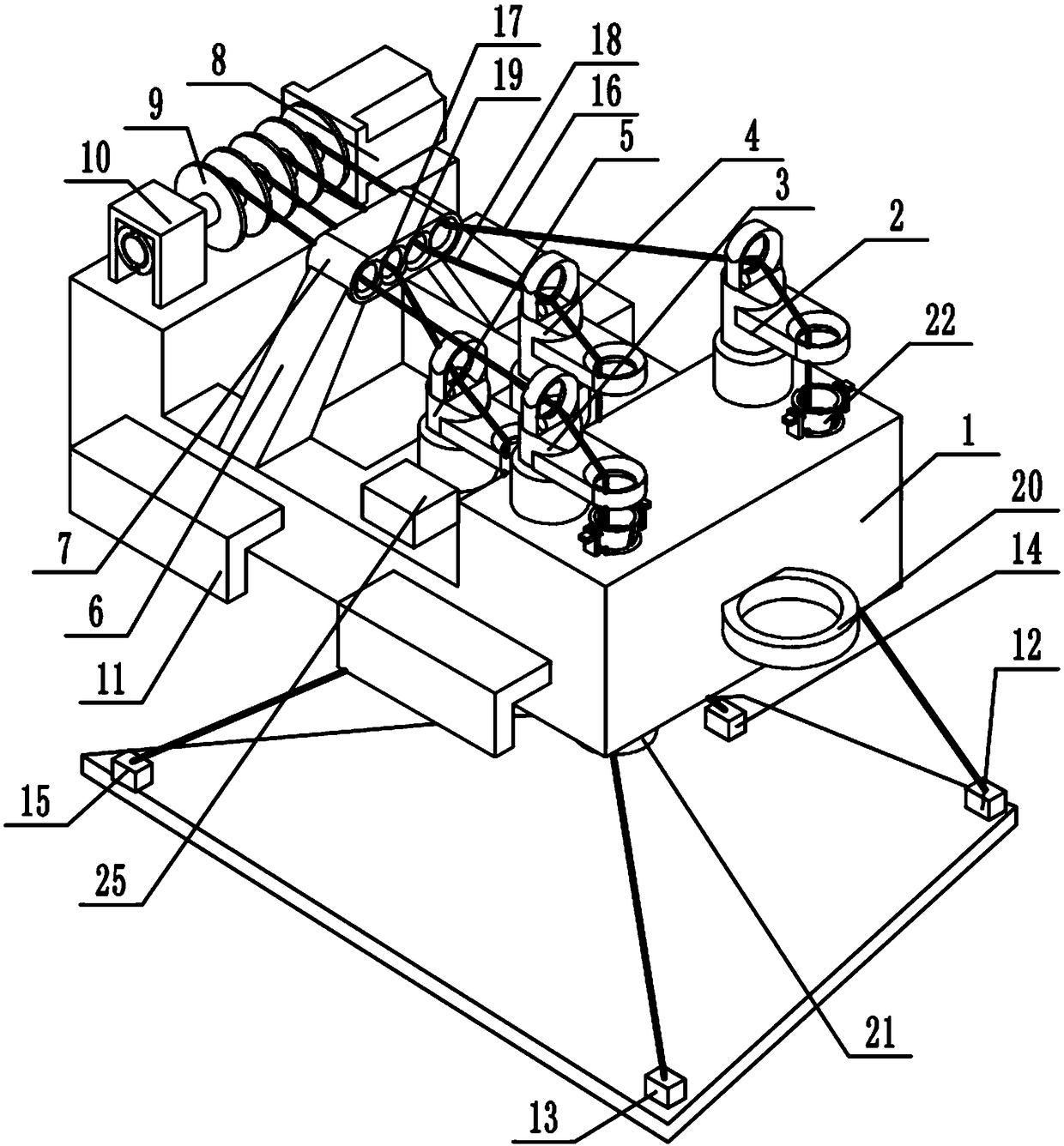

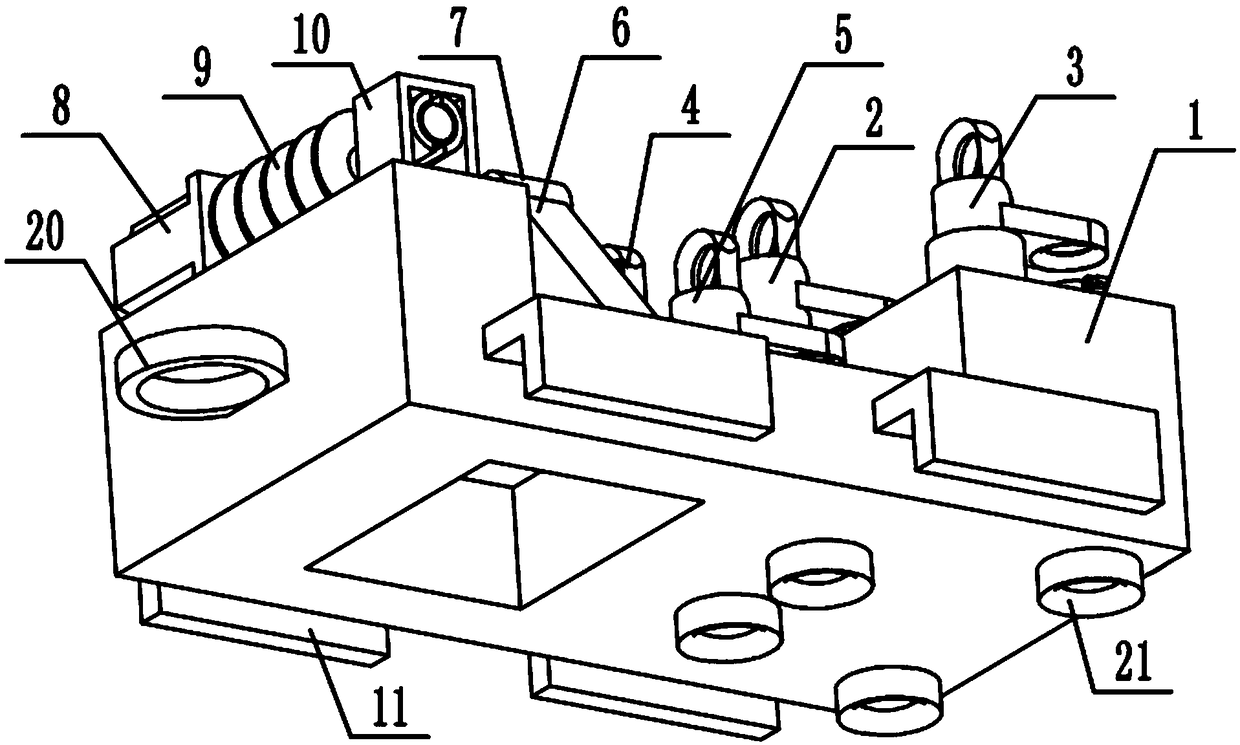

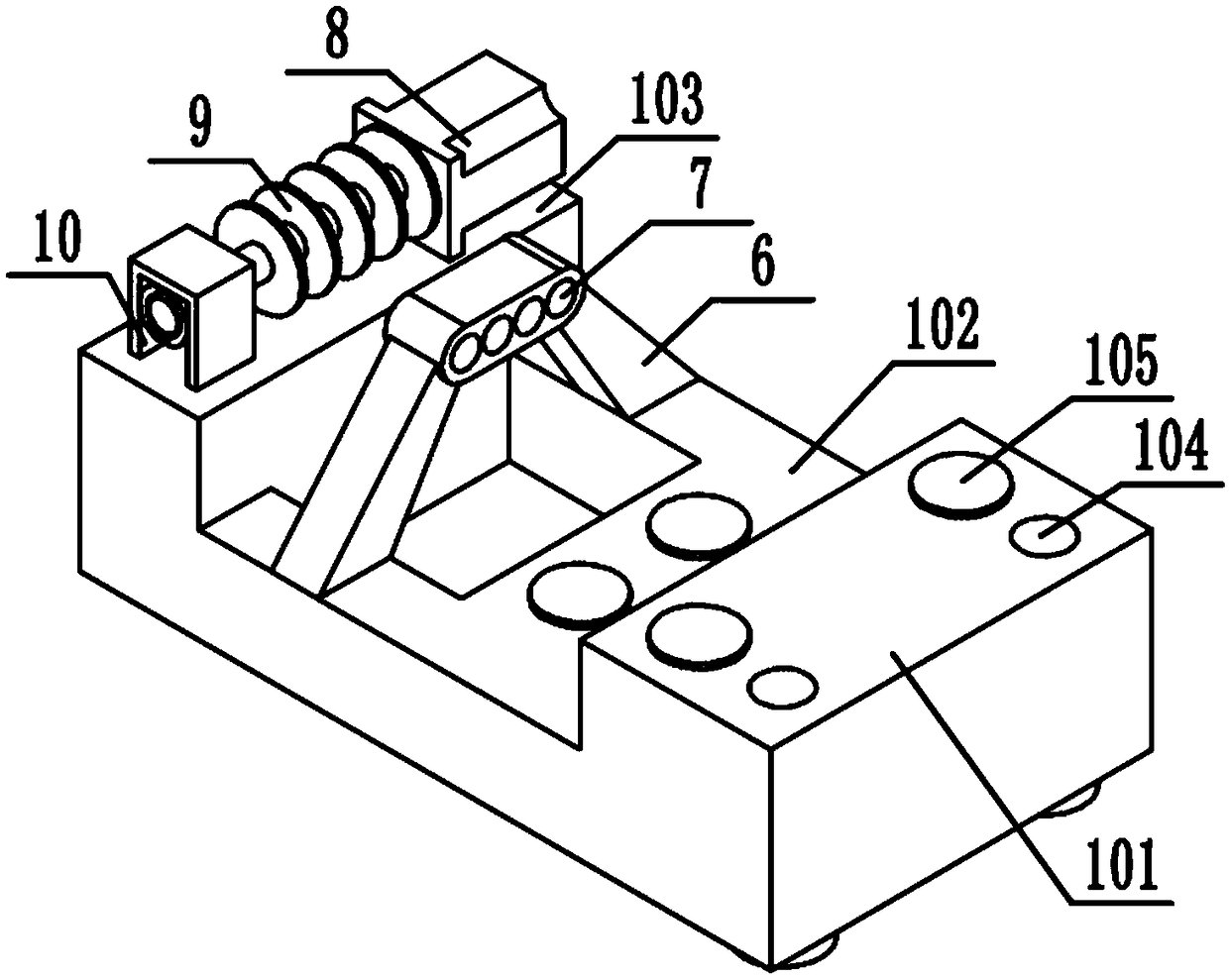

[0024] A special luffing device for quadrilateral steel plates is composed of a frame 1, a first telescopic rod 2, a second telescopic rod 3, a third telescopic rod 4, a fourth telescopic rod 5, a guide groove frame 6, a guide groove 7, a traction Machine 8, rope winding wheel 9, lock 10, chute 11, first hook 12, second hook 13, third hook 14, fourth hook 15, first traction rope 16, second hook The hoisting rope 17, the third hoisting rope 18, the fourth hoisting rope 19, the pull ring 20, the first guide ring 21, the safety lock 22, the second guide ring 23, the third guide ring 24 and the controller 25 are composed of , the frame 1 is composed of a first boss 101, a second concave block 102 and a third boss 103. The first boss 101 is provided with a corresponding first traction rope 16 and a second traction rope The hoisting rope hole 104 of 17, the first boss 101 is provided with a telescopic rod installation bump 105 corresponding to the first hoisting rope 16 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com