Novel high-strength anchorage device

A high-strength, anchorage technology, which is applied in the direction of building reinforcements, bridge parts, structural elements, etc., can solve the problems of wire cutting damage to steel wire cutting, uneven force on the wire splitting board, and reduced anchorage bearing capacity. Achieve the effects of being conducive to axial force bearing, easy to popularize, and improving strength and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

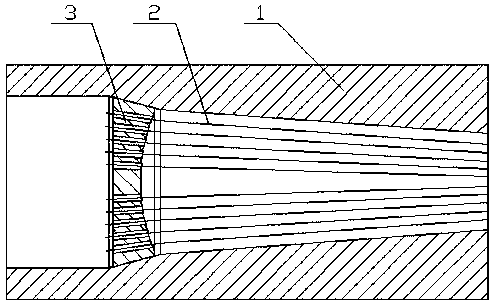

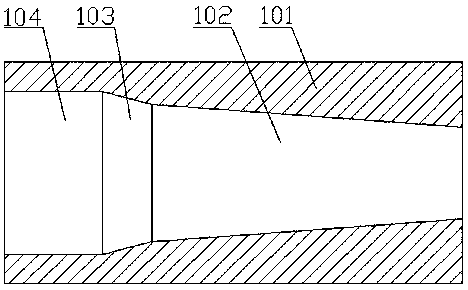

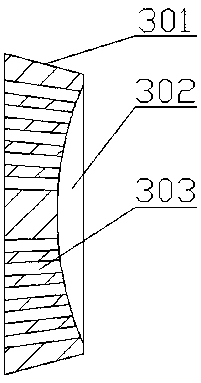

[0014] Such as figure 1 It is a structural schematic diagram of the present invention, a new type of high-strength anchorage, including anchor cup (1), prestressed steel wire (2), and splitter plate (3), characterized in that the splitter plate (3) is placed in the anchor cup Inside (1), the prestressed steel wire (2) passes through the anchor cup (1) and the splitter plate (3), and is fixed on the end face of the splitter plate (3). The anchor cup (1) includes an anchor cup body (101), a first tapered hole (102), a second tapered hole (103), and a through hole (104). The inner hole is divided into three parts, namely the first tapered hole (102), the second taper hole (103), the through hole (104), the taper of the first taper hole (102) is 0.1~0.2, the taper of the second taper hole (103) is 0.2~0.3, the second taper hole Using a taper larger than the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com