Warehouse board

A library board and plate technology, used in building components, thermal insulation, construction, etc., can solve the problems of cumbersome installation and production, cumbersome production process, poor self-bearing capacity, etc., to achieve flexible and convenient assembly, fast and simple production, and good integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

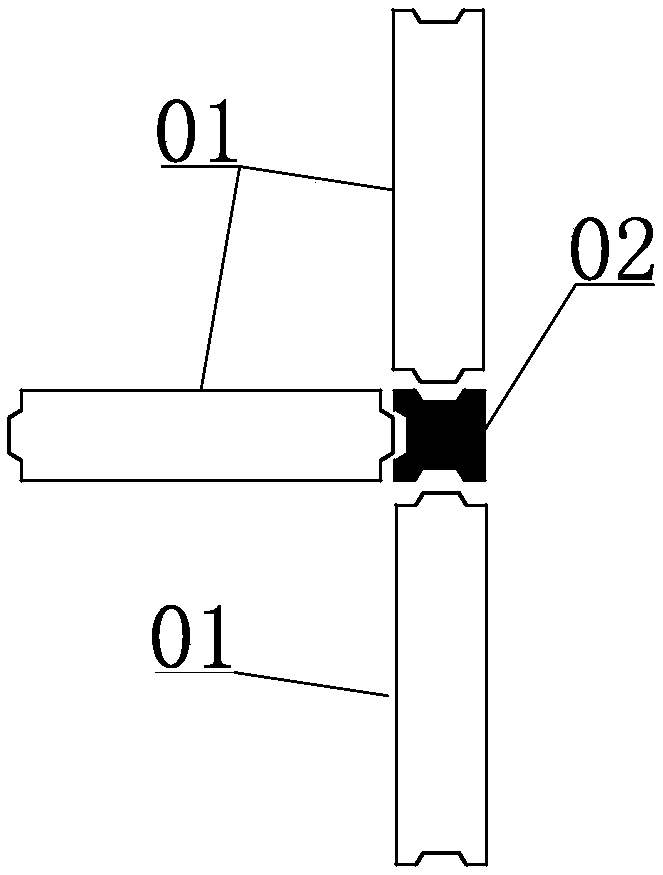

[0023] Example 1, the deformation design of module connection node 02

[0024] The module connection node 02 includes a square cylinder 21 and third recesses 23 respectively provided on three adjacent surfaces of the cylinder 21 .

example 2

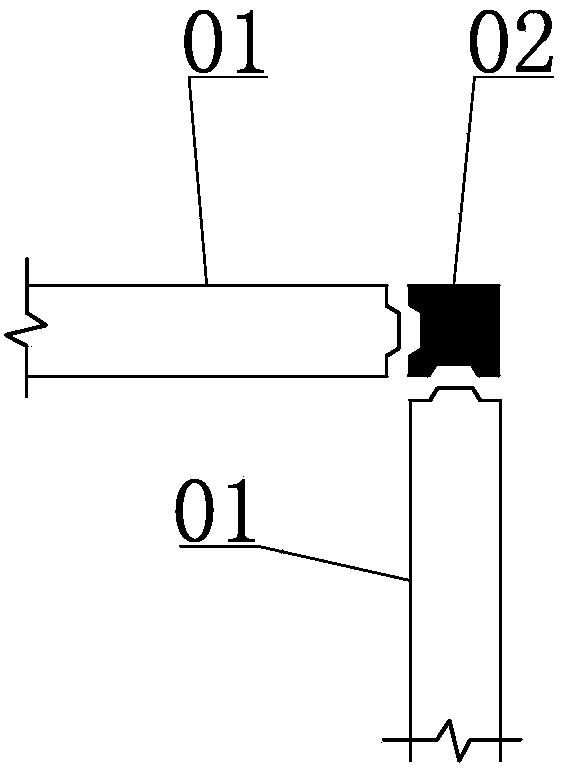

[0025] Example 2, two wall panels are respectively connected to module connection node 02

[0026] The second bump 13 on the plate 11 is inserted into the second recess 22 on one side of the cylinder 21 to form a wallboard, and then the plate 11 and the cylinder 21 are fixed as a whole by hooks hooking the fixing pins; The second protrusion 13 on the plate 11 is inserted into the second recess 22 on the other side of the column 21 to form a wallboard, and then the plate 11 and the column 21 are fixed together by hooks hooking the fixing pins.

example 3

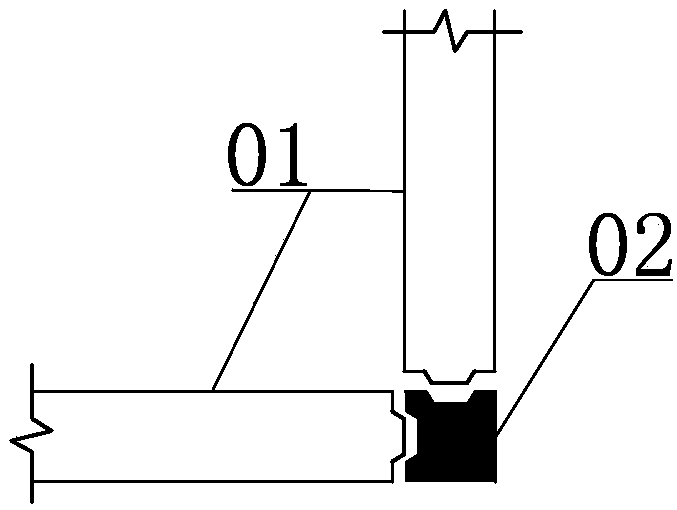

[0027] Example 3, vertical wall panels and horizontal roof panels are respectively connected to module connection node 02

[0028] The first bump 12 on the plate 11 is inserted into the second recess 22 on one side of the cylinder 21 to form a wallboard, and then the plate 11 and the cylinder 21 are fixed as a whole by hooks hooking the fixing pin; The second protrusion 13 on the plate 11 is inserted into the second recess 22 on the other side of the cylinder 21 to form a top plate, and then the plate 11 and the cylinder 21 are fixed together by hooks hooked on the fixing pins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com