Composite template for building

A technology for building and formwork, applied in the direction of building, building structure, formwork/formwork components, etc., can solve the problems of unfriendly waste gas, increase energy and machining cost, etc., to reduce the quantity, reduce the discharge, reduce The effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

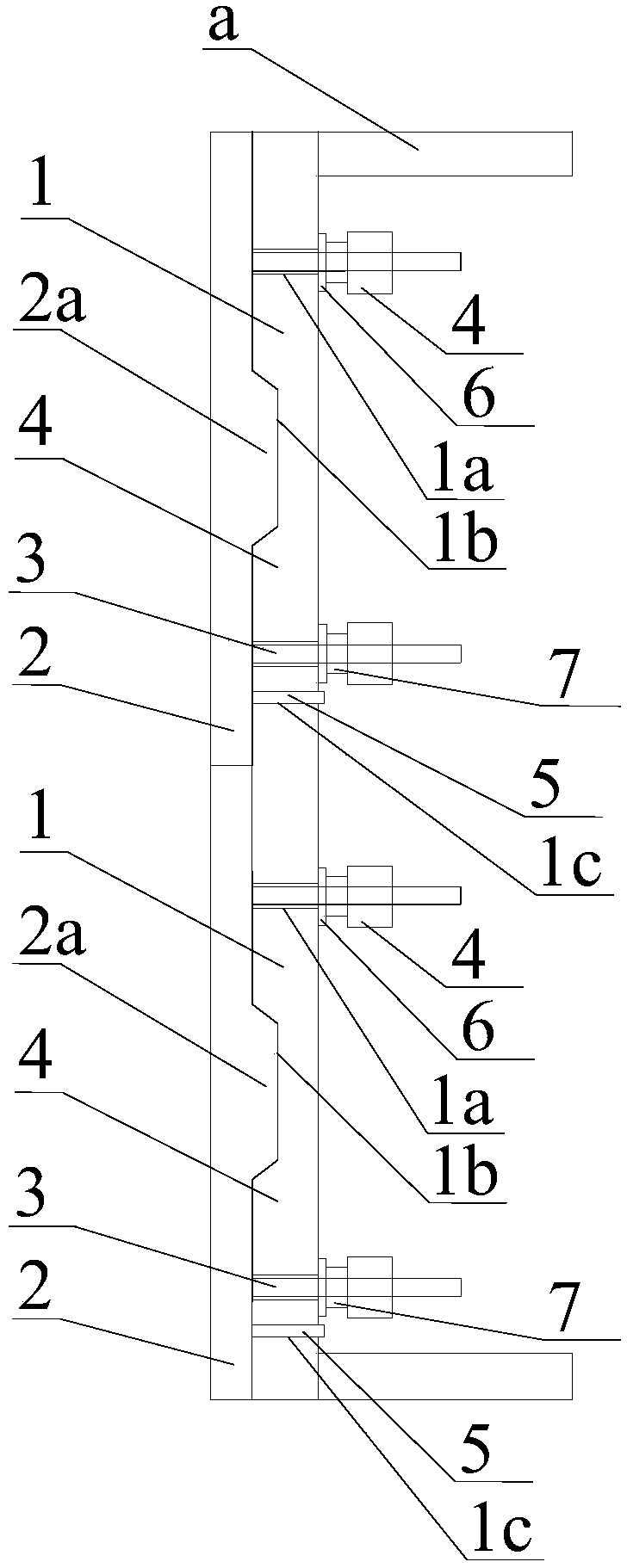

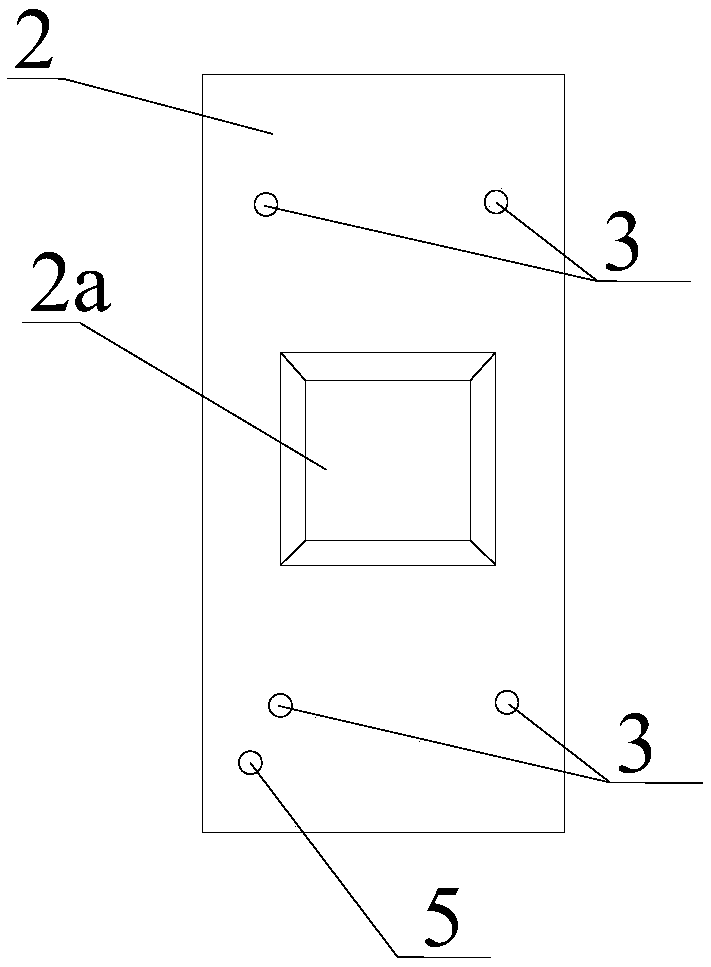

[0025] The embodiment of the invention provides a formwork for composite construction. Such as figure 1 As shown, the formwork for the composite building includes a panel 1 and at least two aluminum alloy panels 2, each side wall of the aluminum alloy panel 2 is equipped with bolts 3, and at least two aluminum alloy panels 2 are arranged along the length direction of the panel 1 Arranged side by side on the surface of the panel 1, the position corresponding to the bolt 3 on the panel 1 is provided with a through hole 1a, the bolt 3 passes through the through hole 1a and is connected with the nut 4, and the side wall of each aluminum alloy plate 2 is provided with a limit As for the protrusion 2a, a groove 1b corresponding to the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com