Cast rod locating cutting device

A technology for positioning cutting and casting rods, which is applied in the field of short casting rod devices and casting rod positioning and cutting devices. The effect of returning to the furnace and increasing the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

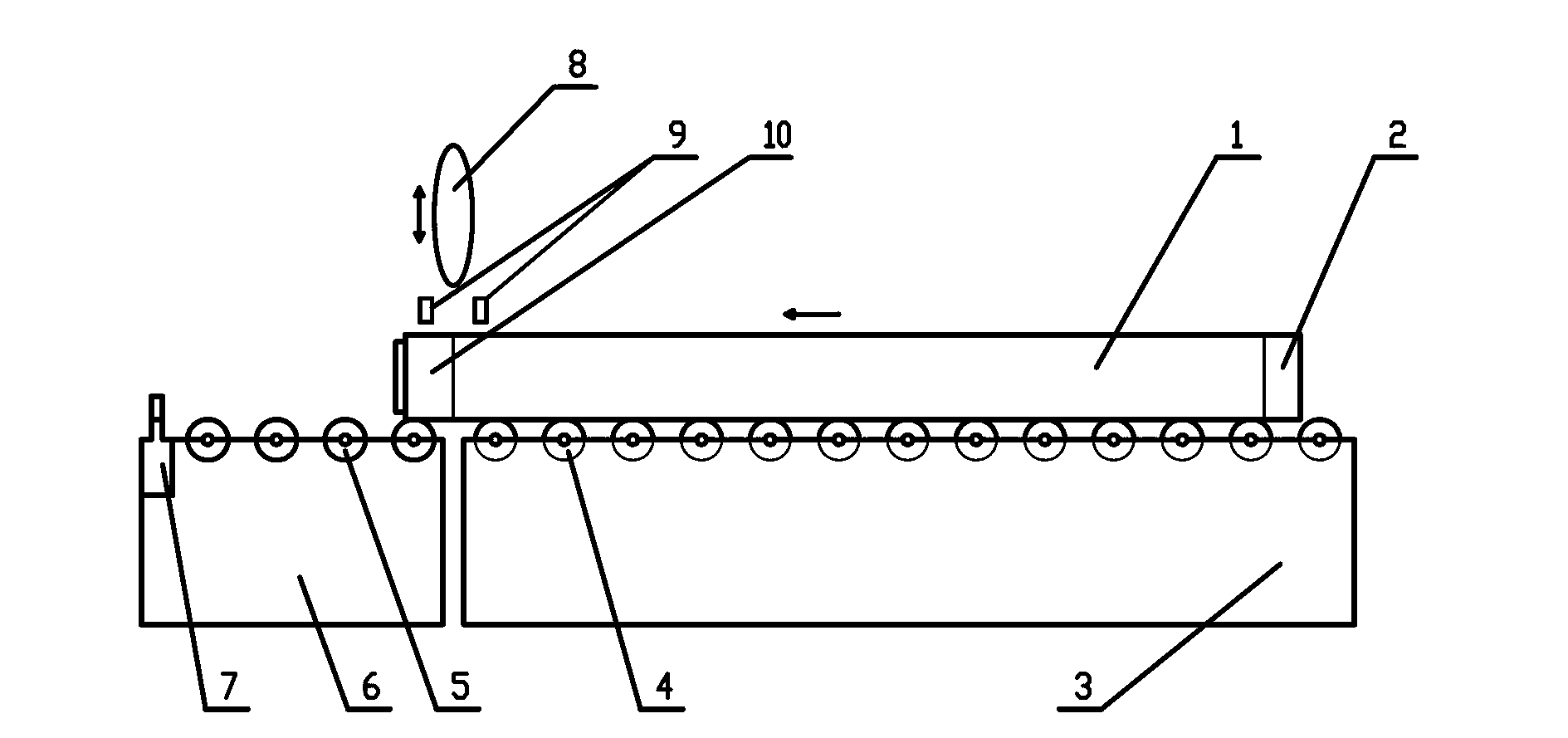

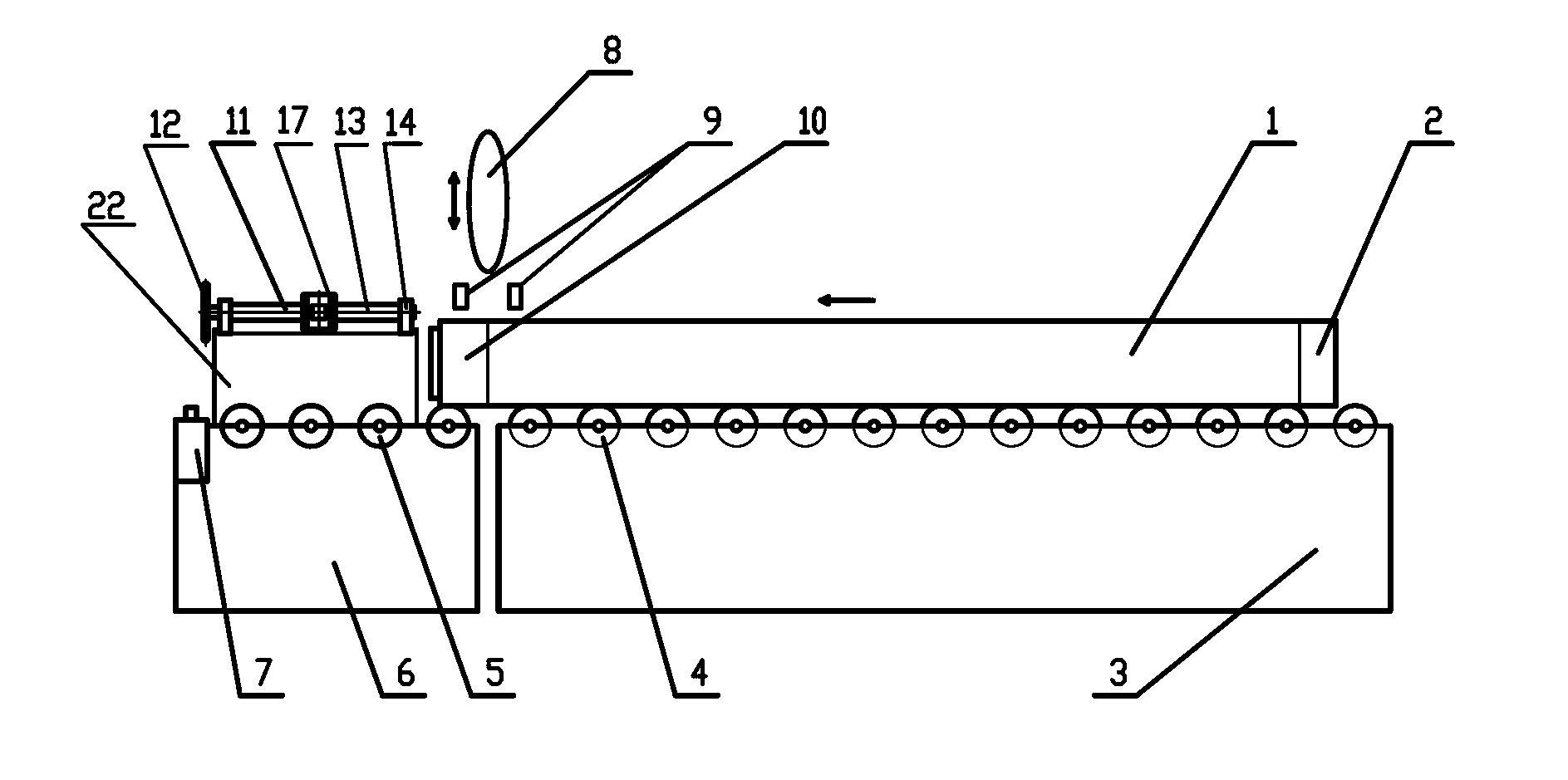

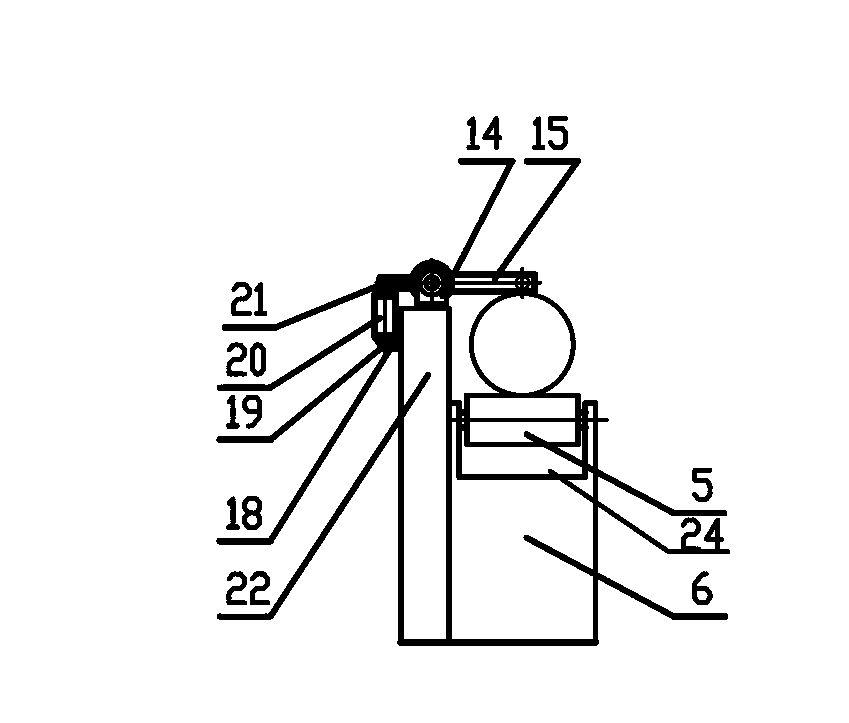

[0011] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0012] Such as Figure 1~4 As shown, it includes long casting rod 1, tail waste area 2, long material transmission table 3, long material transmission wheel 4, short material transmission wheel 5, short material transmission table 6, positioning rod 7, cutting saw blade 8, left and right double pressure Claw 9, head waste area 10, short positioning device 11, hand wheel 12, screw shaft 13, bearing with seat 14, short positioning swing arm 15, bushing 16, lock nut 17, oil cylinder support 18, the first A pin 19, a hydraulic cylinder 20, a second pin 21, a frame 22, a connecting rod 23, a groove 24, and the like.

[0013] Such as Figure 2~4 As shown, the present invention is a casting rod positioning and cutting device. The frame 22 is arranged at the rear part of the short material transfer table 6, and the short material transfer table 6 is placed at the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com