A method for optimizing cutting length of continuous casting tail billet

A technology of continuous casting and sizing, applied in the field of steelmaking, can solve problems such as difficulty in completing optimization work, and achieve the effects of simple structure, reliable data collection, and low cost investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

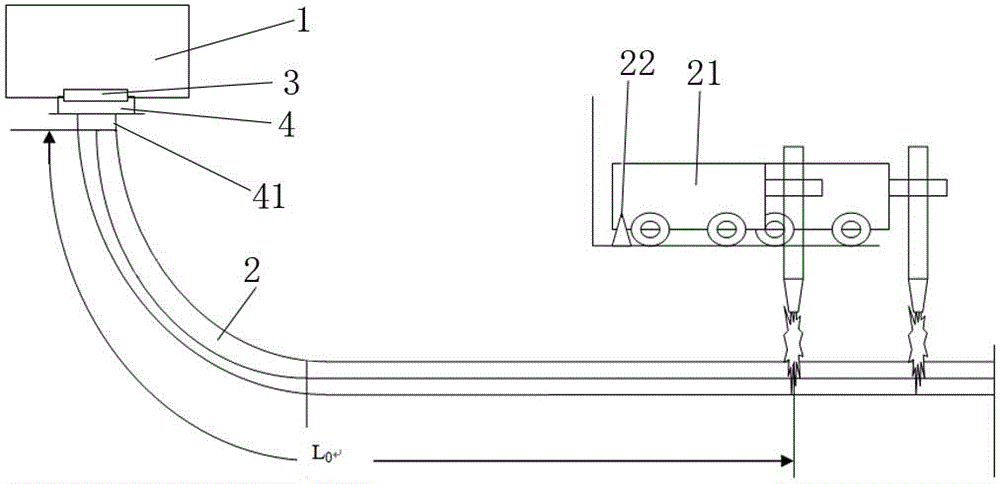

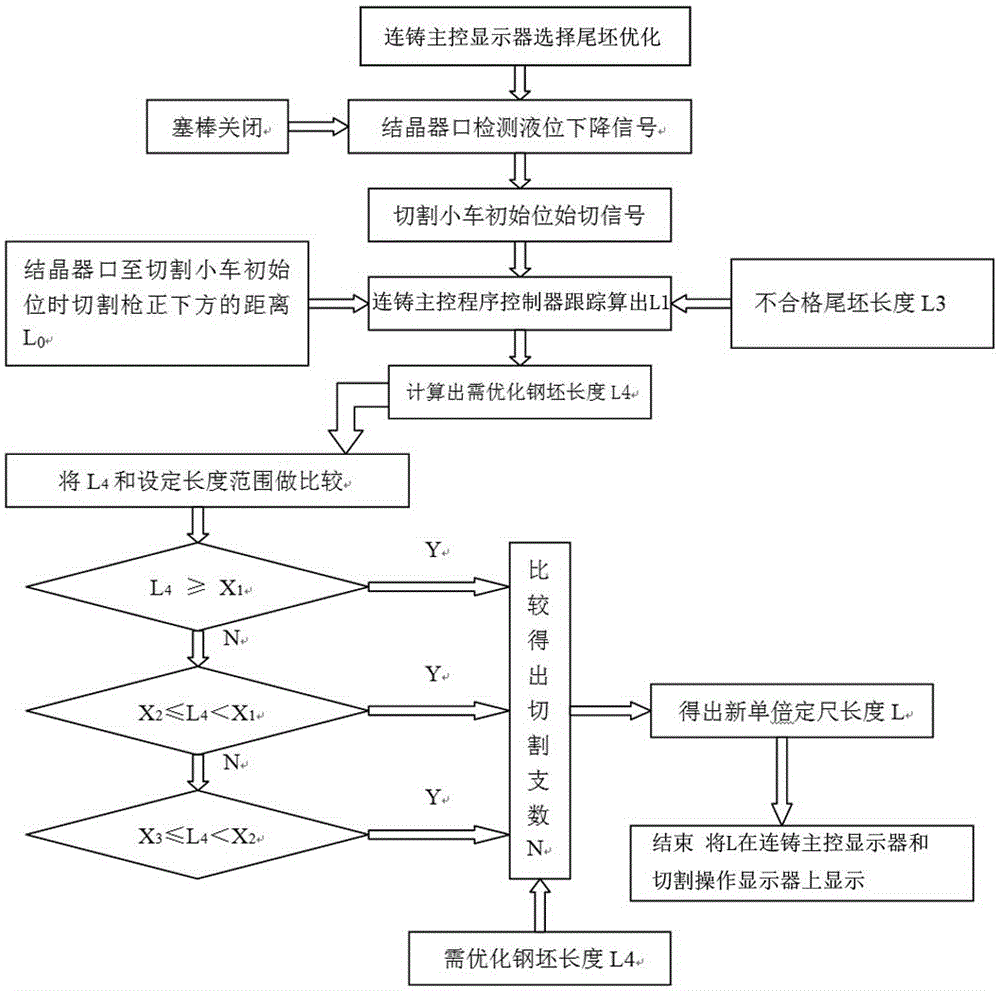

[0043] The method of using a computer program to optimize the cutting of continuous casting tail billet includes the following steps:

[0044] 1. Select the continuous casting tail stock optimization program to start on the continuous casting main control display.

[0045] 2. After closing the stopper of the tundish ladle, the liquid steel level data is collected by the liquid level detector.

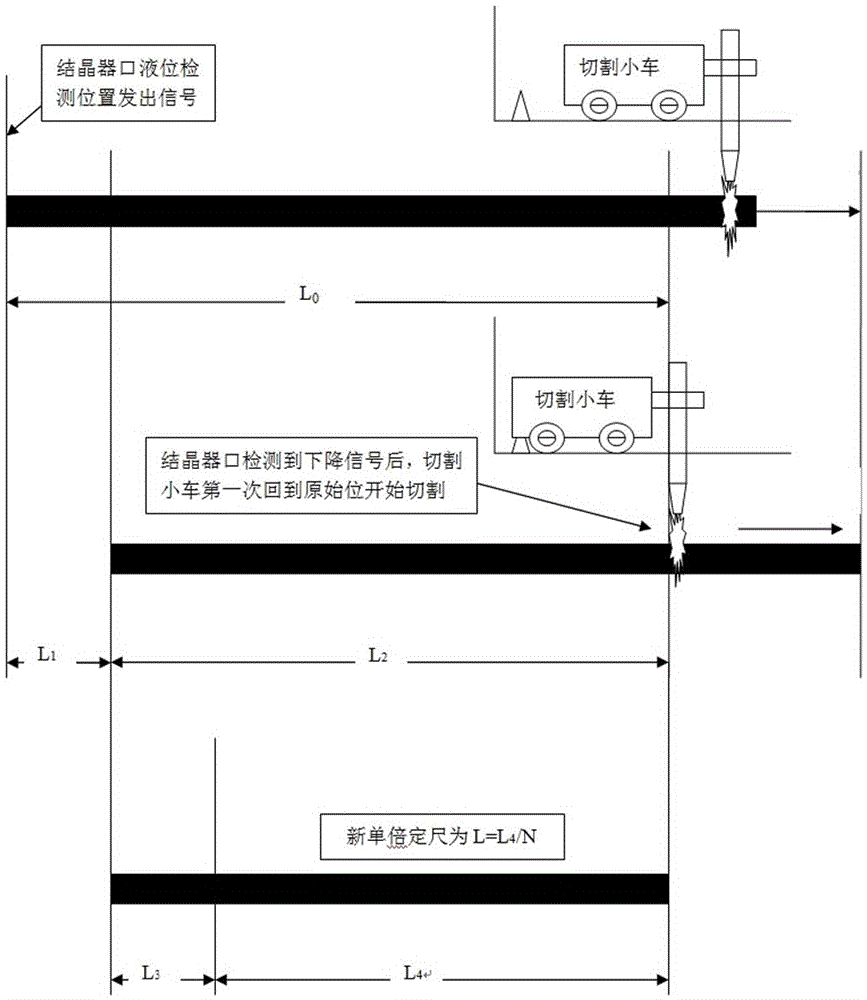

[0046] 3. Send the molten steel level data to the continuous casting main control program controller, and the continuous casting main control program controller calculates the optimized billet length L4.

[0047] Fourth, the continuous casting main control program controller compares and optimizes the pre-set process control requirements of the remaining billet with L4 to obtain a new single slab length L, and sends L to the continuous casting main control display and cutting operation display On display.

[0048] The range of process control requirements is based on the length of the steel trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com